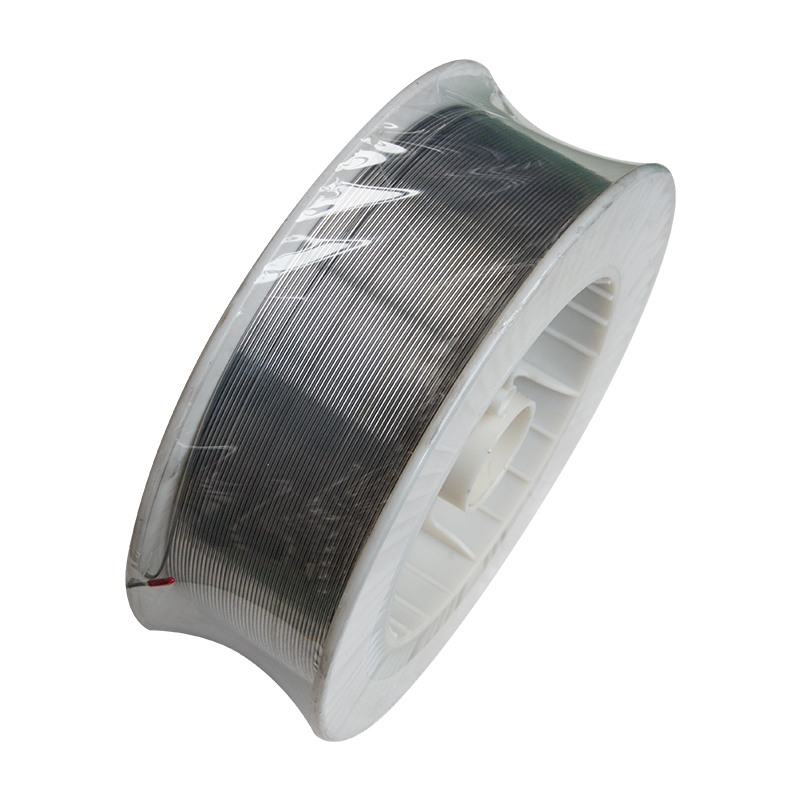

Intambo yokuWelda yeCopper ekhuselweyo ye-Arc yegesi Er70s-6, Sg2

Intshayelelo yocingo lokuwelda olungenaCopper:

Emva kokusetyenziswa kwetekhnoloji ye-nanometer esebenzayo, umphezulu wocingo lokuwelda olungenamthubi alunaso isikali sobhedu kwaye luzinzile ngakumbi ekutyisweni kweengcingo, nto leyo efanelekileyo ngakumbi kwifayili yokuwelda yirobhothi ezenzekelayo ngakumbi. I-arc ibonakala ngokuzinza okuzinzileyo, ukuchitheka okuncinci, ukuguguleka okuncinci kwe-nozzle yoqhagamshelwano lwangoku kunye nobunzulu obukhulu bokufakwa kwe-welding. Indawo yokusebenza yabasebenzi iphuculwe kakhulu kuba ucingo lokuwelda olungenamthubi alunaso umsi wobhedu. Ngenxa yophuhliso lwendlela yonyango lomphezulu omtsha, ucingo lokuwelda olungenamthubi ludlula olunemthubi kwipropati yokulwa nomhlwa, ngezi mpawu zilandelayo.

1. i-arc ezinzileyo kakhulu.

2. Amasuntswana ambalwa okuchitha

3. Ipropati ephezulu yokufunxa ucingo.

4. Ukunciphisa i-arc ngendlela elungileyo

5.Impahla elungileyo yokulwa nomhlwa kumphezulu wentambo yokuwelda.

6. Akukho mveliso yomsi wobhedu.

7. Ukungonakali kakhulu kwe-contact nozzle yangoku.

Ukulumkela:

1. Iiparameter zenkqubo yokuwelda zichaphazela iipropati zoomatshini zentsimbi yokuwelda, kwaye umsebenzisi kufuneka enze isiqinisekiso senkqubo yokuwelda kwaye akhethe ngokufanelekileyo iiparameter zenkqubo yokuwelda.

2. Umhlwa, ukufuma, ioyile, uthuli kunye nezinye izinto ezingcolileyo kwindawo yokuwelda kufuneka zisuswe ngokungqongqo ngaphambi kokuba ziwelding.

Iinkcukacha:Ububanzi: 0.8mm, 0.9mm, 1.0mm, 1.2mm, 1.4mm, 1.6mm, 2.0mm

Ubungakanani bokupakisha: 15kg/20 kg ngespool nganye.

Ulwakhiwo oluqhelekileyo lweekhemikhali zocingo lokuwelda(%)

=========================================================================

| I-elementi | C | Mn | Si | S | P | Ni | Cr | Mo | V | Cu |

| Imfuneko | 0.06-0.15 | 1.40-1.85 | 0.80-1.15 | ≤0.025 | ≤0.025 | ≤0.15 | ≤0.15 | ≤0.15 | ≤0.03 | ≤0.50 |

| Isiphumo sokwenyani se-AVG | 0.08 | 1.45 | 0.85 | 0.007 | 0.013 | 0.018 | 0.034 | 0.06 | 0.012 | 0.28 |

Iimpawu eziqhelekileyo zoomatshini zesinyithi esigciniweyo

==============================================================

| Into yoVavanyo | Tensile strength Rm(Mpa) | Unikeze Amandla Rm(Mpa) | Ukwandiswa I-A(%) | Uvavanyo lweBump lwemodeli ye-V | |

| Ubushushu bovavanyo (ºC) | Ixabiso leMpembelelo (J) | ||||

| Iimfuno | ≥500 | ≥420 | ≥22 | -30 | ≥27 |

| Isiphumo sokwenyani se-AVG | 589 | 490 | 26 | -30 | 79 |

Ubungakanani kunye noluhlu lwangoku olucetyiswayo.

===========================================

| Ububanzi | 0.8mm | 0.9mm | 1.0mm | 1.2mm | 1.6mm | 1.6mm |

| Ii-Amps | 50-140 | 50-200 | 50-220 | 80-350 | 120-450 | 120-300 |

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu