Irhasi eKhuselweyo i-Arc Copper yasimahla yokuWelding i-Er70s-6, i-Sg2 yokuWelding ucingo

Intshayelelo yeCopper free welding wire:

Emva kokusetyenziswa kwetekhnoloji ye-nanometer esebenzayo, umphezulu wocingo lwe-welding olungenalo ubhedu lukhululekile kwisikali sobhedu kwaye luzinzile ngakumbi ekutyaleni ucingo, olufaneleke ngakumbi kwifayile ye-welding ngerobhothi ezenzekelayo ngakumbi. uzinzo, ukutshiza okuncinci, ukunxiba okuncinci kombhobho woqhagamshelwano wangoku kunye nobunzulu obukhulu be-welding deposition.Imeko yokusebenza yabasebenzi iphuculwe kakhulu kuba ucingo lokuwelda olungenalo ubhedu lukhululekile kumsi wobhedu.Ngenxa yophuhliso lwendlela yonyango entsha umphezulu, ucingo lokuwelda olungenalo ubhedu lodlula olo lobhedu olukwipropathi echasene nomhlwa, olunezi mpawu zilandelayo.

1.i-arc ezinzile kakhulu.

2. Amasuntswana esitshizi ambalwa

3.Ipropati ephezulu yokutyisa ucingo.

4.Uthintelo lwe-arc elungileyo

5.Ipropathi elungileyo yokuchasana nomhlwa kumphezulu wocingo lwewelding.

6.Akukho sizukulwana somsi wobhedu.

7. Ukunxiba okuncinci kwe-nozzle yoqhagamshelwano yangoku.

Ukulumkela:

1. Iiparamitha zenkqubo ye-welding zichaphazela iimpawu ze-mechanical weld metal, kwaye umsebenzisi kufuneka enze isiqinisekiso senkqubo ye-welding kwaye ukhethe ngokufanelekileyo iiparitha zenkqubo ye-welding.

2. I-rust, umswakama, ioli, uthuli kunye nezinye izinto ezingcolileyo kwindawo ye-welding kufuneka zisuswe ngokungqongqo phambi kwe-welding.

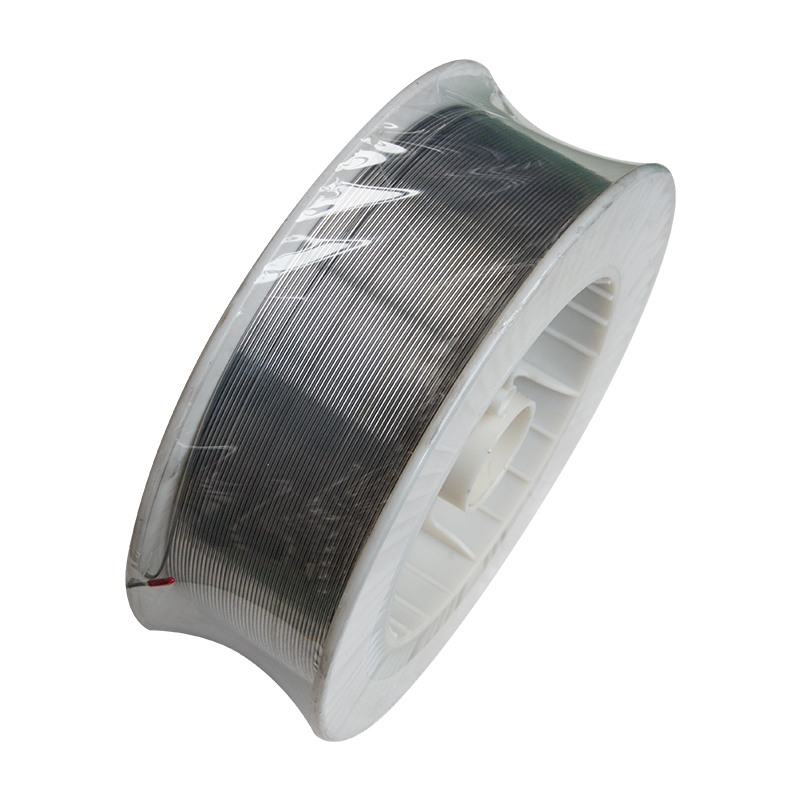

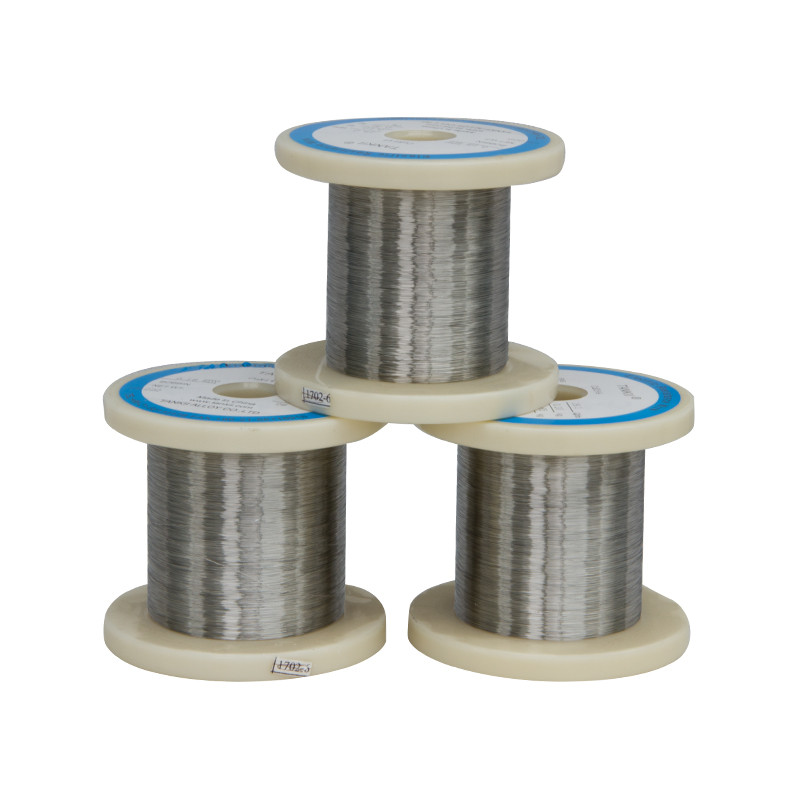

Iinkcukacha:Ububanzi: 0.8mm, 0.9mm, 1.0mm, 1.2mm, 1.4mm, 1.6mm, 2.0mm

Ubungakanani bokupakisha: 15kg / 20 kg ngespool nganye.

Ukuqulunqwa kweMichiza eqhelekileyo yocingo lwe-welding(%)

===========================================

| Isiqalelo | C | Mn | Si | S | P | Ni | Cr | Mo | V | Cu |

| Imfuneko | 0.06-0.15 | 1.40-1,85 | 0.80-1.15 | ≤0.025 | ≤0.025 | ≤0.15 | ≤0.15 | ≤0.15 | ≤0.03 | ≤0.50 |

| Esona siphumo se-AVG | 0.08 | 1.45 | 0.85 | 0.007 | 0.013 | 0.018 | 0.034 | 0.06 | 0.012 | 0.28 |

Iimpawu zeMechanical zentsimbi egciniweyo

==========================================

| Into yovavanyo | Tensile strength Rm(Mpa) | Unikeze Amandla Rm(Mpa) | Elongation A(%) | V imodeli ye-Bump Test | |

| Uvavanyo lweTemp (ºC) | Ixabiso leMpembelelo (J) | ||||

| Iimfuno | ≥500 | ≥420 | ≥22 | -30 | ≥27 |

| Esona siphumo se-AVG | 589 | 490 | 26 | -30 | 79 |

Ubungakanani kunye noluhlu lwangoku olucetyiswayo.

================================

| Ububanzi | 0.8mm | 0.9mm | 1.0mm | 1.2mm | 1.6mm | 1.6mm |

| Amps | 50-140 | 50-200 | 50-220 | 80-350 | 120-450 | 120-300 |