Wamkelekile kwiwebhusayithi zethu!

I-Tankii S-Type Thermocouple Sensor Ukulinganisa Ubushushu Obuphezulu Kwemizi-mveliso kunye Nokuqonda Okuchanekileyo

Ingcaciso yeMveliso

I-S-Type Thermocouple Sensor (0-1300℃, Ubude obuyi-250mm)

Isishwankathelo seMveliso

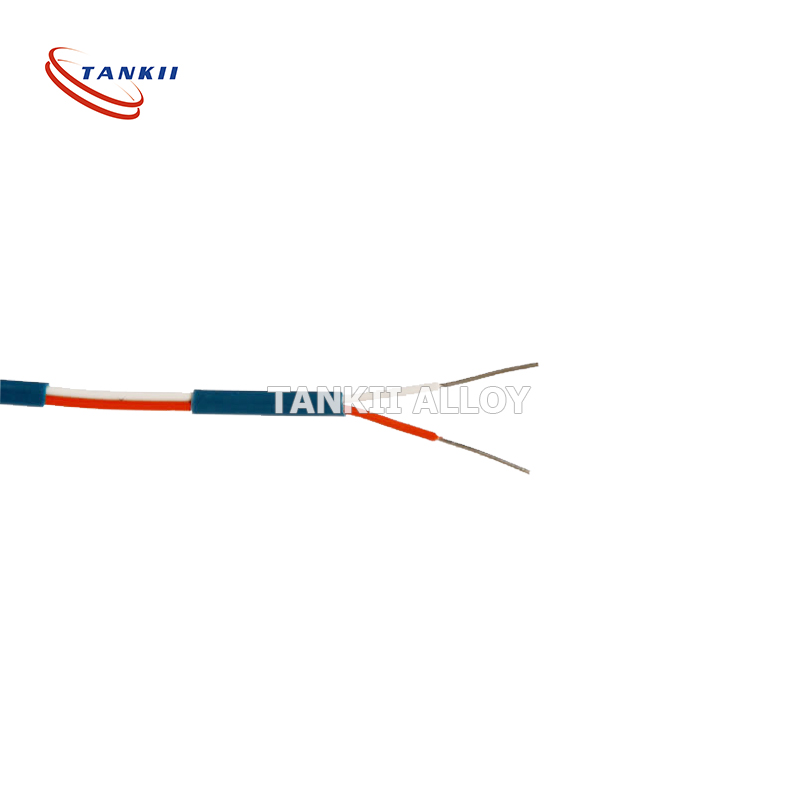

I-S-type thermocouple sensor (platinum-rhodium 10%-platinum, Pt10Rh/Pt) evela kwiTankii Alloy Material yinxalenye yokulinganisa ubushushu obuphezulu echanekileyo kakhulu eyenzelwe iimeko ezishushu kakhulu. Ngoyilo olulungiselelweyo oluyi-250mm ubude iyonke, ityhubhu yokukhusela i-ceramic enobubanzi obuyi-7-8mm, kunye nentambo yomqhubi enobubanzi obuyi-0.2mm, le sensor ifumana ukufunyanwa kobushushu ngokuchanekileyo kwi-0-1300℃ ngesiphumo seSeebeck se-noble metal alloys. Iyadibanisauzinzo oluhle kakhulu lobushushu obuphezulu,ukushukuma okuphantsi komlinganiselokunyeukuqina kwesakhiwo okuqinileyo—okuyenza ibe lolona khetho lukhethwayo kwiinkqubo zobushushu obuphezulu ezifana nokubeka esweni ubushushu besithando soshishino, iprofayili yobushushu yonyango lobushushu, kunye novavanyo lokuthembeka kobushushu obuphezulu becandelo le-elektroniki.

Iimpawu eziMiselweyo kunye neSiseko soLwakhiwo

- Ibanga leSensor: Uhlobo lwe-S (IEC 60584-1 Udidi 1; olulingana ne-ANSI/ASTM E230 Uhlobo S) – i-thermocouple yesinyithi esinobuhle ene-Pt10Rh (i-electrode elungileyo) kunye nee-conductor ze-Pt (i-electrode engalunganga) ezicocekileyo

- Iinkcukacha ezingundoqo: Ubushushu obuphakathi kwe-0-1300℃ (ukusetyenziswa kwexesha elifutshane ukuya kuthi ga kwi-1400℃ kangangemizuzu eyi-≤30); ubude obupheleleyo yi-250mm (ukulinganisa ubude bokuphela yi-50mm, ubude bocingo lwe-lead yi-200mm); ityhubhu yokukhusela i-ceramic ububanzi obungaphandle yi-7-8mm (ubukhulu bodonga yi-1.2-1.5mm); ububanzi bocingo lwe-conductor yi-0.2mm (ukunyamezelana ± 0.01mm)

- Imigangatho ehambelanayo: IEC 60584-1 (udidi lokuchaneka kwe-thermocouple), GB/T 1672-1997 (ii-thermocouple zeplatinum-rhodium), ASTM E230-19 (umgangatho wee-thermocouple zesinyithi ezihloniphekileyo)

- Umenzi: Izinto zeTankii Alloy, eziqinisekiswe yi-ISO 9001 kunye ne-ISO 14001, ezinokukwazi ukunyibilikisa i-alloy yesinyithi esidumileyo kunye nokukwazi ukulinganisa i-sensor.

Iingenelo eziphambili (Zenzelwe i-0-1300℃ kunye neenkcukacha zolwakhiwo)

1. Ubungakanani bokuGcina ubushushu obuphezulu Ukuchaneka kunye nozinzo

Isebenzisa intambo yomqhubi ye-Pt10Rh/Pt engu-99.99% ecocekileyo kakhulu (ububanzi obuyi-0.2mm) enomxube we-alloy ofanayo—ukuchaneka komlinganiselo kufikelela kwiKlasi yoku-1 (impazamo ≤±1.5℃ kwi-0-600℃, ≤±0.25% t kwi-600-1300℃, t=ubushushu obulinganisiweyo). Emva kweeyure ezili-1000 zokusebenza okuqhubekayo kwi-1200℃, i-thermoelectric potential drift yi-<3μV (ilingana nempazamo yobushushu <0.4℃)—ingcono kakhulu kune-K-type thermocouples (drift >10μV kwi-800℃) kwaye ifanelekile ukujonga ubushushu obuphezulu ixesha elide.

2. Ukuqina Kwesakhiwo Okulungiselelweyo

- Ityhubhu yoKhuseleko lweCeramic: 7-8mm ububanzi bangaphandle be-alumina ceramic ephezulu (umxholo we-Al₂O₃ ≥95%) kunye nokumelana nobushushu obuphezulu ukuya kuthi ga kwi-1600℃, amandla okucinezela ≥150MPa—eyahlula ngokufanelekileyo isinyithi esinyibilikisiweyo, uthuli lwesithando, kunye neegesi ezirhabaxa ngelixa iqinisekisa ukusebenza kakuhle kokudluliselwa kobushushu (ukuqhuba kobushushu ≥20 W/(m·K) kwi-800℃).

- Uyilo lweConductor kunye noQhagamshelo: Umqhubi we-0.2mm ububanzi ulinganisela ukuguquguquka kunye namandla obushushu obuphezulu (amandla okutsalwa ≥350MPa kwi-25℃, ≥150MPa kwi-1300℃); isiphelo sokulinganisa sisebenzisa i-spot welding (ububanzi be-weld spot yi-0.3-0.4mm) ukuqinisekisa imveliso eqinileyo ye-thermoelectric potential ngaphandle kokumelana nokuchukumisa.

- Ukulingana koBude obupheleleyo: Ubude obupheleleyo obuyi-250mm (isiphelo sokulinganisa esingu-50mm + ucingo lwe-lead oluyi-200mm) lulungiselelwe ukufakwa kodonga olusecaleni lwe-oven yemizi-mveliso—luthintela ukugoba kakhulu kocingo lwe-lead ngelixa luqinisekisa ukuba isiphelo sokulinganisa sifikelela kwindawo yobushushu obuphakathi.

3. Ukuthembeka okuhlengahlengisiweyo kwesicelo

I-sensor inokumelana okuhle kwe-oxidation (yenza ifilimu yokukhusela i-PtO₂ exineneyo kubushushu obuphezulu) kunye nokumelana nokutshatyalaliswa kobushushu (ingamelana nokutshintsha kobushushu obuyi-500℃/min ngaphandle kokuqhekeka kwetyhubhu ye-ceramic). Intambo ye-lead isebenzisa i-insulation ye-Teflon yobushushu obuphezulu (ubushushu bokusebenza obuyi--60℃ ukuya kwi-260℃) ukuthintela iisekethe ezimfutshane kwiindawo zokusebenzela zobushushu obuphezulu, kwaye i-terminal ixhotyiswe ngesixhumi esiqhelekileyo se-M12 sokunxibelelana ngokukhawuleza kwii-transmitters zobushushu.

Iinkcukacha zobugcisa

| Uphawu | Ixabiso (Eliqhelekileyo) | Ukubaluleka kweSicelo |

|---|---|---|

| Uhlobo lweSensor | Uhlobo lwe-S (Pt10Rh/Pt) | Isinyithi esihloniphekileyo esicocekileyo kakhulu siqinisekisa uzinzo kubushushu obuphezulu |

| Uluhlu lobushushu | 0-1300℃ (iyaqhubeka); 0-1400℃ (ixesha elifutshane ≤30min) | Igubungela uninzi lweenkqubo zoshishino ezishushu kakhulu |

| Ukuchaneka kokulinganisa | Udidi 1: ±1.5℃ (0-600℃); ±0.25% t (600-1300℃) | Ihlangabezana neemfuno zonyango lobushushu oluchanekileyo (umz., ukucima iindawo zeemoto) |

| Ubude obupheleleyo | 250mm (Yenzelwe wena) | Yenzelwe ukufakwa kodonga olusecaleni kwesithando somlilo |

| Iinkcukacha zeCeramic Tube | Ububanzi obungaphandle 7-8mm | Ukukhusela ubushushu ngendlela elinganiselayo kunye nokusebenza kakuhle kokudlulisa ubushushu |

| Ububanzi bentambo yomqhubi | 0.2mm (ukunyamezelana ± 0.01mm) | Iqinisekisa uzinzo kunye nokuguquguquka kwamandla ombane |

| Amandla ombane asebenzisa i-thermoelectric (1000℃) | 10.591mV (xa kuthelekiswa ne-0℃ reference junction) | Iyahambelana nemilinganiselo yokulinganisa eqhelekileyo ye-IEC 60584-1 |

| Ixesha Lokuphendula (τ₅₀) | ≤2s (emoyeni kwi-800℃) | Iyakwazi ukuziqhelanisa notshintsho olutshintshayo lobushushu kunyango lobushushu |

| Ubomi beNkonzo (1200℃ iyaqhubeka) | iiyure eziyi-≥1000 | Inciphisa ukugcinwa rhoqo kwee-oven zoshishino |

Iinkcukacha zeMveliso

| Into | Inkcazo | Inzuzo yokusebenza |

|---|---|---|

| Izinto zoKhuseleko lweThubhu | I-95% ye-alumina ephezulu yodongwe | Ukumelana nobushushu obuphezulu kunye nokumelana nokugqwala |

| Ukufakwa kweConductor | I-alumina ceramic bead ecocekileyo kakhulu (icandelo le-250℃); iTeflon (icandelo lobushushu begumbi) | Ithintela ukujikeleza okufutshane kubushushu obuphezulu |

| Isixhumi seTerminal | Isixhumi esingangeni manzi se-M12 (inqanaba lokhuseleko lwe-IP65) | Ukufakwa ngokukhawuleza kunye nothuli/ukungangeni manzi |

| Isatifikethi soLungiso | Ingxelo yokulinganisa enokulandeleka ye-NIST (ukhetho) | Ihlangabezana neemfuno zokuqinisekiswa kwemetrology |

| Ukupakisha | Ifoam engashukumiyo + ibhokisi yekhadibhodi; ukupakishwa kwento enye | Ithintela ukwaphuka kwetyhubhu yeseramikhi ngexesha lokuthuthwa |

| Ukwenziwa ngokwezifiso | Ubude obupheleleyo (100-1000mm); izinto zetyhubhu yeseramikhi (99% ye-alumina ye-1600℃); uhlobo lwesixhumi (isixhumi esincinci sezixhobo ze-elektroniki) | Ilungelelanisa neemfuno zofakelo olukhethekileyo kunye nesicelo |

Imizekelo yeSicelo esiQhelekileyo

1. Iinkqubo zoShishino olunobushushu obuphezulu

Isetyenziselwa ukujonga ubushushu kwii-oven zesinyithi zonyango lobushushu (umz., i-stainless steel annealing kwi-900-1100℃) kunye nee-oven ze-ceramic sintering (1200-1300℃)—ityhubhu ye-ceramic eyi-7-8mm iyamelana nokukhukuliseka kothuli lwe-oven, kwaye ukuchaneka kweKlasi loku-1 kuqinisekisa umgangatho wemveliso ohambelanayo.

2. Uvavanyo lokuthembeka kweCandelo le-elektroniki

Isetyenziswa kwiimvavanyo zokuguga ezisebenzisa ubushushu obuphezulu zeetships ze-semiconductor kunye neemodyuli zamandla (0-1200℃)—i-0.2mm thin conductor kunye nexesha lokuphendula ngokukhawuleza (≤2s) zibamba ngokuchanekileyo utshintsho lobushushu oludlulayo ngexesha lokufudumeza kwecandelo, zibonelela ngenkxaso yedatha yokuvavanya ukuthembeka.

3. Ukulinganisa ubushushu obuphezulu beSensor yoxinzelelo

Njengesalathiso sobushushu kwiinkqubo zokulinganisa ubushushu obuphezulu be-sensor yoxinzelelo (umz., ukulinganisa ii-sensor zoxinzelelo lwenjini yeemoto kwi-800-1000℃)—ukuphuma kwamandla ombane okuzinzileyo kuqinisekisa ukuchaneka kokulinganisa kwee-sensor zoxinzelelo.

4. Uphando lweLebhu olunobushushu obuphezulu

Isetyenziswa kwiilabhoratri zesayensi yezinto ezibonakalayo xa kuvavanywa utshintsho lwesigaba esishushu kakhulu (0-1300℃)—ubude obuyi-250mm bufanelekile kwiifeni ezibekwe phezulu, kwaye ukulinganiswa kwe-NIST okunganyanzelekanga kuyahlangabezana neemfuno zokulandelela idatha yophando.

Uqinisekiso loMgangatho kunye neNkxaso yoBugcisa

Izinto zeTankii Alloy zisebenzisa ulawulo lomgangatho olunezigaba ezintathu kwiisensa ze-thermocouple zohlobo lwe-S:

- Uhlolo lomqhubi: Uhlalutyo lokwakheka kwe-alloy ye-XRF (luqinisekisa umxholo we-Pt10Rh oyi-9.5-10.5%) kunye novavanyo lokumelana neprobe enamanqaku amane (luqinisekisa ubunyulu).

- Uvavanyo lweNdibano: Ukulinganiswa kobushushu obuphezulu kwisithando somlilo esichanekileyo (ukuchaneka kobushushu ±0.1℃) kunye novavanyo lomothuko olushushu (imijikelo engama-50 ye-25℃-1300℃).

- Uqinisekiso lokugqibela: Uvavanyo oluqhubekayo lokusebenza iiyure ezingama-24 kwi-1200℃ ukuqinisekisa ukusebenza kokushukuma kunye novavanyo lokungena kwamanzi lwesixhumi (IP65).

Iisampuli zasimahla (ezinengxelo yokulinganisa) kunye nesikhokelo sokufakela kwindawo ziyafumaneka xa ziceliwe. Iqela lethu lobuchwephesha libonelela ngezisombululo ezenzelwe wena ezifana nokwenza ngcono ubude benzwa kwiifeni ezikhethekileyo kunye nesikhokelo sokufanisa neetransmitter zobushushu ukuqinisekisa ukusebenza kakuhle kokulinganisa.

Bhala umyalezo wakho apha uze uwuthumele kuthi

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu