Wamkelekile kwiwebhusayithi zethu!

I-Tankii J-Type Thermocouple Bare Wire SWG30/SWG25/SWG19 Ubushushu obuphezulu

Ingcaciso yeMveliso

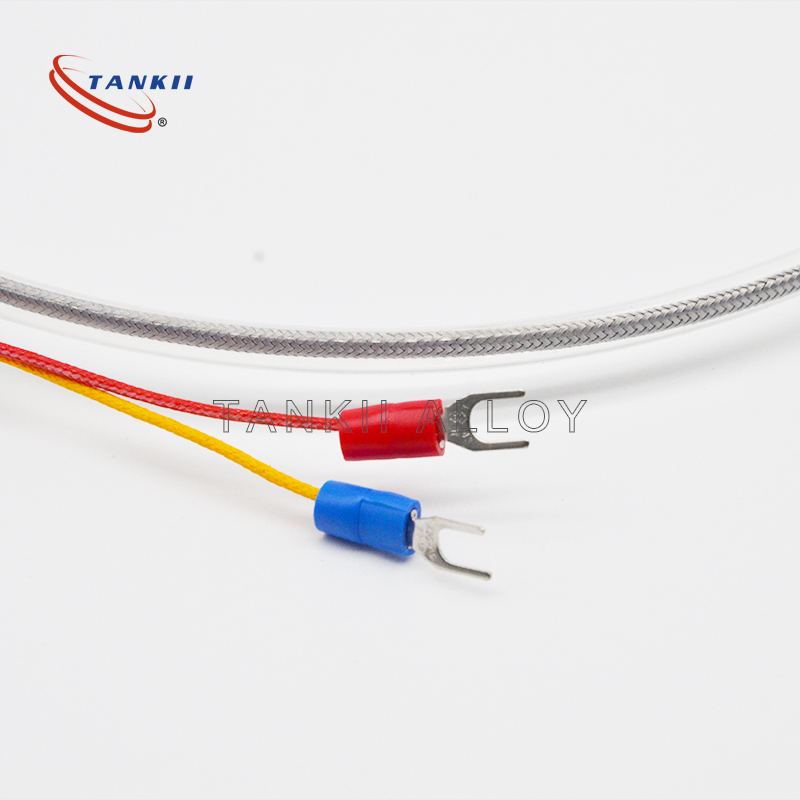

Uhlobo J Thermocouple Bare Wire (SWG30/SWG25/SWG19)

Isishwankathelo seMveliso

Uhlobo lwe-thermocouple bare wire, into eqonda ubushushu ngendlela echanekileyo eyenziwe yiTankii Alloy Material, inee-conductors ezimbini ze-alloy ezahlukeneyo—i-iron (positive leg) kunye ne-constantan (i-copper-nickel alloy, negative leg)—eyenzelwe ukulinganisa ubushushu ngendlela echanekileyo kwiindawo ezinobushushu obuphakathi. Ifumaneka kwiigeyiji ezintathu ze-wire standard: SWG30 (0.305mm), SWG25 (0.51mm), kunye ne-SWG19 (1.02mm), le wire bare isusa ukuphazamiseka kwe-insulation, okwenza ukuba ilungele ukuhlanganiswa kwe-thermocouple ngokwezifiso, ukulinganiswa kobushushu obuphezulu, kunye nezicelo ezifuna ukunxibelelana ngokuthe ngqo nemidiya elinganisiweyo. Isebenzisa ubuchwepheshe be-Huona bokunyibilikisa kunye nokuzoba i-alloy, igeyiji nganye igcina ukunyamezelana okungqongqo kunye neempawu ze-thermoelectric ezizinzileyo, iqinisekisa ukuhambelana kuzo zonke iibhetshi.

Iimpawu eziQhelekileyo

- Uhlobo lwe-Thermocouple: J (Iron-Constantan)

- Iigeyiji zocingo: SWG30 (0.315mm), SWG25 (0.56mm), SWG19 (1.024mm)

- Imigangatho yaMazwe ngaMazwe: Iyahambelana ne-IEC 60584-1, ASTM E230, kunye ne-GB/T 4990

- Uhlobo: Ucingo olungenanto (olungagqunywanga, ukuze lugqunywe/lukhuselwe ngokwezifiso)

- Umenzi: Izinto zeTankii Alloy, eziqinisekiswe yi-ISO 9001 kwaye zilinganiswe ngokwemigangatho yobushushu belizwe

Iingenelo eziphambili (xa kuthelekiswa neengcingo zohlobo lwe-J ezifakwe i-insulation kunye nezinye iintlobo ze-thermocouple)

Esi sisombululo sentambo engenanto sibonakala ngokuguquguquka kwaso, ukuchaneka, kunye nokuguquguquka ngokukodwa kwegeyiji:

- Ukusebenza Okulungelelaniswe NeeGauge: I-SWG30 (igauge encinci) inika ukuguquguquka okuphezulu kokufakelwa kwindawo exineneyo (umz., ii-sensors ezincinci); I-SWG19 (igauge etyebileyo) inika amandla oomatshini aphuculweyo kwiindawo zoshishino; I-SWG25 ilinganisela ukuguquguquka kunye nokuqina kokusetyenziswa ngokubanzi.

- Ukuchaneka kweThermoelectric okuPhezulu: Ivelisa amandla e-electromotive azinzileyo (i-EMF) anovakalelo lwe-~52 μV/°C (kwi-200°C), ephumelela kakhulu kwi-Type K kuluhlu lwe-0-500°C, kunye nokuchaneka kweKlasi 1 (ukunyamezela: ±1.5°C okanye ±0.25% yokufundwa, nokuba yeyiphi na enkulu).

- Ukuguquguquka kwengcingo engenanto: Akukho kufakwa kwengcingo kwangaphambili kuvumela abasebenzisi ukuba benze ngokwezifiso ukhuseleko (umz., iityhubhu zeseramikhi, ukugoba kwefiberglass) ngokusekelwe kwiimfuno ezithile zobushushu/ukubola, ukunciphisa inkunkuma evela kwiingcingo ezifakwe ingcingo ngaphambili ezingafanelaniyo.

- Ixabiso Eliphantsi: I-iron-constantan alloy ifikeleleka lula kune-thermocouples zesinyithi esixabisekileyo (ii-Types R/S/B) ngelixa inika uvakalelo oluphezulu kunohlobo lwe-K, nto leyo eyenza ukuba ilungele ukulinganisa ubushushu obuphakathi (0-750°C) ngaphandle kokuchitha imali eninzi.

- Ukumelana Okuhle Nokuxinana: Isebenza ngokuthembekileyo kwiindawo ezixinanayo ukuya kuthi ga kwi-750°C; umqhubi wentsimbi wenza umaleko we-oxide okhuselayo onciphisa ukushukuma, okwandisa ubomi benkonzo xa kuthelekiswa neengcingo zentsimbi ezingaxutywanga.

Iinkcukacha zobugcisa

| Uphawu | SWG30 (0.315mm) | SWG25 (0.56mm) | SWG19 (1.024mm) |

|---|---|---|---|

| Izinto zomqhubi | Okuhle: Intsimbi; Okungalunganga: Constantan (Cu-Ni 40%) | Okuhle: Intsimbi; Okungalunganga: Constantan (Cu-Ni 40%) | Okuhle: Intsimbi; Okungalunganga: Constantan (Cu-Ni 40%) |

| Ububanzi obuqhelekileyo | 0.305mm | 0.51mm | 1.02mm |

| Ukunyamezelana kobubanzi | ± 0.01mm | ± 0.015mm | ± 0.02mm |

| Uluhlu lobushushu | Iyaqhubeka: 0-700°C; Ixesha elifutshane: 750°C | Iyaqhubeka: 0-750°C; Ixesha elifutshane: 800°C | Iyaqhubeka: 0-750°C; Ixesha elifutshane: 800°C |

| I-EMF kwi-100°C (xa kuthelekiswa ne-0°C) | 5.268 mV | 5.268 mV | 5.268 mV |

| I-EMF kwi-750°C (xa kuthelekiswa ne-0°C) | 42.919 mV | 42.919 mV | 42.919 mV |

| Ukumelana nomqhubi (20°C) | ≤160 Ω/km | ≤50 Ω/km | ≤15 Ω/km |

| Amandla okuThamba (20°C) | ≥380 MPa | ≥400 MPa | ≥420 MPa |

| Ukwandiswa (20°C) | ≥20% | ≥22% | ≥25% |

Iinkcukacha zeMveliso

| Into | Inkcazo |

|---|---|

| Umphezulu wokugqiba | I-annealed eqaqambileyo (engena-oxide, iRa ≤0.2μm) |

| Ifomu yoNikezelo | IiSpools (ubude: 50m/100m/300m ngegeyiji nganye) |

| Ucoceko lweeKhemikhali | Intsimbi: ≥99.5%; Constantan: Cu 59-61%, Ni 39-41%, ukungcola ≤0.5% |

| Ukulinganisa | Ilandelelwa kwi-NIST/China National Institute of Metrology (CNIM) |

| Ukupakisha | Ivalwe nge-vacuum kwiingxowa ezizaliswe yi-argon (ukuthintela i-oxidation); iiplastiki ezifakwa kwiibhokisi ezingangenisi manzi |

| Ukwenziwa ngokwezifiso | I-cut-to-length (ubuncinci i-1m), i-alloy purity ekhethekileyo (i-high-purity iron for calibration), okanye iziphelo ezifakwe kwi-tin |

Izicelo eziqhelekileyo

- I-Custom Thermocouple Assembly: Isetyenziswa ngabavelisi bezinzwa ukwenza ii-probes ezinokhuselo olukhethekileyo (umz., ii-probes ezine-sheathed ceramic kwii-oven, ii-probes ezine-stainless steel-sheathed ze-liquids).

- Uvavanyo lobushushu kwimizi-mveliso: Ukulinganisa ngokuthe ngqo ekucutshungulweni kokutya (ukubhaka kwi-oven, 100-300°C) kunye nokubumba iplastiki (ubushushu bokunyibilika, 200-400°C)—I-SWG25 ikhethwa ngenxa yokulinganisela ukuguquguquka kunye namandla.

- Izixhobo zokulinganisa: Izinto ezibhekisa kwii-calibrators zobushushu (SWG30 kwiiseli zokulinganisa ezixineneyo).

- Uvavanyo lweeMoto: Ukubeka iliso kumaqondo obushushu enjini kunye nenkqubo yokukhupha umoya (SWG19 yokumelana nokungcangcazela).

- Uphando lweLebhu: Ukujonga iprofayili yobushushu kwiimvavanyo zesayensi yezinto (0-700°C) apho kufuneka khona ubushushu obuqhelekileyo.

Izinto zeTankii Alloy zijongana novavanyo lomgangatho oluqinileyo lwentambo engenanto yohlobo J: uvavanyo lozinzo lwe-thermoelectric (ii-cycles ezili-100 ze-0-750°C), ukuhlolwa kobukhulu (i-laser micrometry), kunye nohlalutyo lokwakheka kweekhemikhali (i-XRF). Iisampuli zasimahla (i-1m nge-gauge) kunye neziqinisekiso zokulinganisa ziyafumaneka xa ziceliwe. Iqela lethu lobuchwephesha libonelela ngesikhokelo esilungiselelwe wena—kubandakanya ukhetho lwe-gauge kwizicelo ezithile kunye neendlela ezilungileyo zokusongelwa/ukuwelda—ukuqinisekisa ukusebenza kakuhle kwi-thermocouple setups ezenziwe ngokwezifiso.

Bhala umyalezo wakho apha uze uwuthumele kuthi

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu