Ikhoyili yoMcu wocingo lokumelana neFeCrAl oluyi-0.05mm Ubungqingqwa

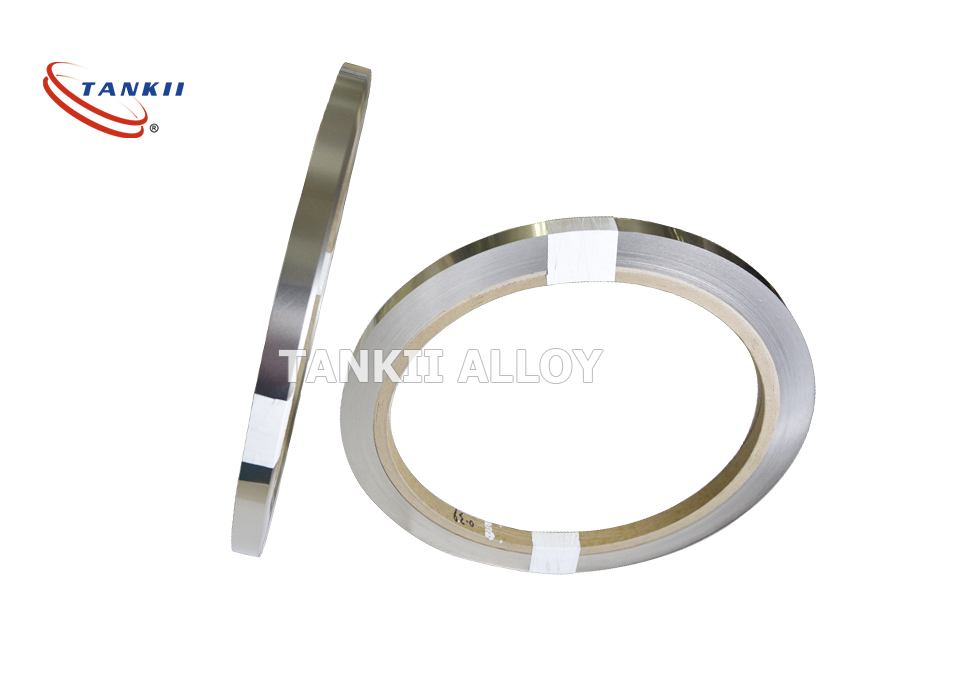

I-FeCrAl AlloyI-Foil/Strip Coil 0.05mm Ubungqingqwa beMetallic Honeycomb Substrates

Umxholo ophezulu we-aluminiyamu, xa udibene nomxholo ophezulu we-chromium kubangela ukuba ubushushu bokulinganisa bunyuke bufikelele kwi-1425 C (2600F); Phantsi kwesihloko, eziI-alloy ye-FeCrAlii-s zithelekiswa nee-alloys zesiseko ze-Fe kunye ne-Ni ezisetyenziswa rhoqo. Njengoko kunokubonwa kuloo theyibhile,I-alloy ye-FeCrAlIi-s zineempawu eziphezulu xa zithelekiswa nezinye ii-alloys kwiindawo ezininzi.

Kufuneka kuqatshelwe ukuba, ngexesha lokutshintshana kweemeko zobushushu, ukongezwa kwe-yttrium kwi-AF alloy eyaziwa ngokuba zii-Fecralloys alloys, kuphucula ukunamathela kwe-oxide ekhuselayo, okwenza ubomi benkonzo yezinto ezikwi-AF alloy bube bude kunobo be-A-1 grade.

Iingcingo ze-Fe-Cr-Al zenzelwe ii-alloy ze-aluminium zesinyithi ze-chromium eziqulathe ubungakanani obuncinci bezinto ezisabelayo ezifana ne-yttrium kunye ne-zirconium kwaye ziveliswa ngokunyibilikisa, ukuqengqeleka kwentsimbi, ukubumba, ukutsalwa, unyango lomphezulu, uvavanyo lokulawula ukumelana, njl.

Ucingo lwe-Fe-Cr-Al lwenziwe ngomatshini wokupholisa ozenzekelayo okhawulezayo apho amandla ombane alawulwa yikhompyutha, afumaneka njengocingo kunye neribhoni (umcu).

Iimpawu kunye neenzuzo

1. Ubushushu obuphezulu obusetyenziswayo, ubushushu obuphezulu obusetyenziswayo bungafikelela kwi-1400C (0Cr21A16Nb, 0Cr27A17Mo2, njl.njl.)

2. Umlinganiselo wokumelana nobushushu obuphantsi

3. I-coefficient yokwandiswa kobushushu ephantsi kune-Ni-base super-alloys.

4. Ukumelana okuphezulu kombane

5. Ukumelana nokugqwala okuhle phantsi kobushushu obuphezulu, ingakumbi phantsi komoya oqulethe iisulfide

6. Umthwalo ophezulu womphezulu

7. Ayikwazi ukurhubuluza

8. Ixabiso eliphantsi lezinto ezikrwada, Uxinano oluphantsi kunye nexabiso eliphantsi xa kuthelekiswa nocingo lweNichrome.

9. Ukumelana okuphezulu kwe-oxidation kwi-800-1300ºC

10. Ubomi benkonzo ende

Ukwakheka kwezigaba ze-alumina eziguquguqukayo ngenxa yokuxinana kweemveliso zorhweboI-alloy ye-FeCrAliingcingo (ubukhulu obuyi-0.5 mm) kubushushu obahlukeneyo kunye namaxesha ahlukeneyo zihloliwe. Iisampulu zifakwe i-oxidation emoyeni kusetyenziswa i-thermogravimetric analyzer (TGA). Imo yeesampulu ezifakwe i-oxidation yahlalutywa kusetyenziswa i-Electronic Scanning Electron Microscope (ESEM) kwaye i-X-ray kuhlalutyo lomphezulu yenziwe kusetyenziswa i-Energy Dispersive X-Ray (EDX) analyzer. Indlela ye-X-Ray Diffraction (XRD) yasetyenziswa ukuchaza isigaba sokukhula kwe-oxide. Lonke uphando lubonise ukuba kunokwenzeka ukukhulisa i-gamma alumina kwindawo ephezulu kumphezuluI-alloy ye-FeCrAlimiphezulu yentambo xa i-isothermally oxidized engaphezulu kwe-800°C kangangeeyure ezininzi.

| I-aluminiyam ye-Chrome yentsimbi | |||||||

| OCr25Al5 | I-CrAl25-5 | 23.0 | 71.0 | 6.0 | |||

| OCr20Al5 | I-CrAl20-5 | 20.0 | 75.0 | 5.0 | |||

| OCr27Al7Mo2 | 27.0 | 65.0 | 0.5 | 7.0 | 0.5 | ||

| OCr21Al6Nb | 21.0 | 72.0 | 0.5 | 6.0 | 0.5 | ||

| I-aluminiyam ye-Chrome yentsimbi | ||

| OCr25Al5 | Ingasetyenziswa kwiimeko zokusebenza ukuya kuthi ga kwi-1350°C, nangona inokuba buthathaka. | Izinto zokufudumeza zee-oven ezishushu kakhulu kunye nezifudumezi ezikhazimlayo. |

| OCr20Al5 | I-alloy ye-ferromagnetic enokusetyenziswa kumaqondo obushushu afikelela kwi-1300°C. Ifanele isetyenziswe kwindawo eyomileyo ukuze kuthintelwe ukugqwala. Ingaqhekeka xa amaqondo obushushu aphezulu. | Izinto zokufudumeza zee-oven ezishushu kakhulu kunye nezifudumezi ezikhazimlayo. |

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu