Ikhoyili yentwasahlobo

pinkcazo yemveliso

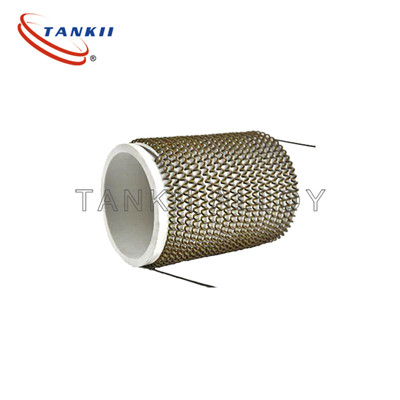

Inkampani yethu ivelisa iingcingo ze-alloy zokufudumeza zombane ze-iron-chromium-aluminium kunye ne-nickel-chromium ezikumgangatho ophezulu, ezisebenzisa amandla eengcingo zesithando somlilo ezilawulwa yikhompyutha kwaye zijijeke zibe yimo ngumatshini wokujika ozenzekelayo okhawulezayo. Iimpawu zale mveliso: ukumelana nobushushu obuphezulu, ukufudumeza ngokukhawuleza, ubomi benkonzo ende, ukumelana okuzinzileyo, ukuphambuka kwamandla amancinci, i-pitch efanayo emva kokusolula, umphezulu okhanyayo nococekileyo; isetyenziswa kakhulu kwiifeni zombane ezincinci, iifeni zomoya opholileyo, izixhobo zokufudumeza kunye nomoya opholileyo, ii-oveni ezahlukeneyo, iityhubhu zokufudumeza zombane kunye nezixhobo zasekhaya, njl. Iibhari ezahlukeneyo zefeni zombane ezingezizo ezisemgangathweni zoshishino kunye nezoluntu zinokuyilwa kwaye ziveliswe ngokweemfuno zomsebenzisi.

| Amandla W | Vi-oltage V | Ububanzi mm | OD mm | Li-ength (Isalathiso) mm | Wisibhozo g |

| 300 | 220 | 0.25 | 3.7 | 122 | 1.9 |

| 500 | 220 | 0.35 | 3.9 | 196 | 4.3 |

| 600 | 220 | 0.40 | 4.2 | 228 | 6.1 |

| 800 | 220 | 0.50 | 4.7 | 302 | 11.1 |

| 1000 | 220 | 0.60 | 4.9 | 407 | 18.5 |

| 1200 | 220 | 0.70 | 5.6 | 474 | 28.5 |

| 1500 | 220 | 0.80 | 5.8 | 554 | 39.0 |

| 2000 | 220 | 0.95 | 6.1 | 676 | 57.9 |

| 2500 | 220 | 1.10 | 6.9 | 745 | 83.3 |

| 3000 | 220 | 1.20 | 7.1 | 792 | 98.3 |

Ubushushu kunye nokwakheka kweekhemikhali kwintambo yokufudumeza

| Ibanga | Ubuninzi. Iyaqhubeka Ubushushu bokusebenza. | I-Cr% | I-Ni% | I-Al% | I-Fe% | I-Re% | I-Nb% | I-Mo% |

| I-Cr20Ni80 | 1200℃ | 20~23 | Ibhala. |

|

|

|

|

|

| I-Cr30Ni70 | 1250℃ | 28~31 | Ibhala. |

|

|

|

|

|

| Cr15Ni60 | 1150℃ | 15~18 | 55~61 |

| Ibhala. |

|

|

|

| I-Cr20Ni35 | 1100℃ | 18~21 | 34~37 |

| Ibhala. |

|

|

|

| I-TANKII APM | 1425℃ | 20.5~23.5 |

| 5.8 | Ibhala. | / |

|

|

| 0Cr27Al7Mo2 | 1400℃ | 26.5~27.8 |

| 6~7 | Ibhala. |

|

| 2 |

| 0Cr21Al6Nb | 1350℃ | 21~23 |

| 5~7 | Ibhala. |

| 0.5 |

|

| 0Cr25Al5 | 1250℃ | 23~26 |

| 4.5~6.5 | Ibhala. |

|

|

|

| 0Cr23Al5Y | 1300℃ | 22.5~24.5 |

| 4.2~5.0 | Ibhala. |

|

|

|

| 0Cr19Al3 | 1100℃ | 18~21 |

| 3~4.2 | Ibhala. |

|

|

|

Iimpawu eziphambili zobugcisa zentambo ye-FeCrAl alloy:

①Ubushushu bokusetyenziswa buphezulu, ubushushu bokusetyenziswa kwentambo ye-aluminium ye-iron-chromium emoyeni bunokufikelela kwi-1300℃;

②Ubomi benkonzo ende;

③Umthwalo womphezulu ovumelekileyo mkhulu;

⑤Umxhuzulane othile mncinci kune-nickel-chromium alloy; ④Ukumelana nokuxinana kwe-oxidation kulungile, kwaye ifilimu ye-AI2O3 eyenziwe emva kokuxinana inokumelana okuhle kweekhemikhali kunye nokuxhathisa okuphezulu;

⑥Ukumelana okuphezulu;

⑦Ukumelana kakuhle nesalfure;

⑧Ixabiso liphantsi kakhulu kunele-nickel-chromium alloy;

⑨Ingxaki kukuba njengoko ubushushu busanda, bubonakalisa ukuba buthambile, kwaye amandla xa kushushu aphezulu aphantsi.

Iimpawu zentambo yesitovu sombane se-nickel-chromium zezi:

① Amandla aphezulu kubushushu obuphezulu;

②Ukuba ipholile emva kokusetyenziswa ixesha elide, loo nto ayiyi kuba buthathaka;

③Ukuphuma kwe-alloy ye-Ni-ming e-oxidized ngokupheleleyo kuphezulu kune-alloy ye-Fe-Cr-Al;

④Akukho magnetism;

⑤Ngaphandle kwesimo sezulu sesalfure, sinokumelana nokugqwala okungcono

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu