I-Spiral Electric Resistor CuNi Alloy 1 – 5 Mohm Yezinto Zokufudumeza Umoya Opholileyo

I-Spiral Electric Resistor Nicr Alloy 1 – 5 Mohm Yezinto Zokufudumeza Ezisebenzisa I-Air Conditioner

1. Inkcazelo Jikelele yezinto eziphathekayo

uConstantanyi-alloy ye-copper-nickel eyaziwa ngokuba yiI-Eureka,PhambilikunyeIsikhephe. Ngokwesiqhelo iqulathe i-55% yobhedu kunye ne-45% ye-nickel. Uphawu lwayo oluphambili kukumelana kwayo, okuhlala kuhleli kubushushu obahlukeneyo. Ezinye ii-alloys ezine-coefficients ezifanayo zobushushu obuphantsi ziyaziwa, njenge-manganin (Cu).86Mn12Ni2).

Ukulinganisa iintlobo ezinkulu kakhulu, i-5% (50 000 microstrian) okanye ngaphezulu, i-annealed constantan (i-P alloy) zizinto zegridi ezikhethwa rhoqo. I-Constantan kule fomu ilula kakhulu.i-ductilekwaye, kubude begauge obuyi-0.125 intshi (3.2 mm) nangaphezulu, bunokuhluzwa bufikelele kwi->20%. Nangona kunjalo, kufuneka kukhunjulwe ukuba phantsi kwe-high cyclic strains i-P alloy iya kubonisa utshintsho oluthile oluhlala luhleli kumjikelo ngamnye, kwaye ibangele utshintsho olufanelekileyo.unothiukutshintsha kwe-strain gauge. Ngenxa yolu phawu, kunye nokuthambekela kokusilela kwegridi ngaphambi kwexesha ngokuxinwa okuphindaphindiweyo, i-P alloy ayikhuthazwa rhoqo kwizicelo ze-cyclic strain. I-P alloy iyafumaneka ngeenombolo ze-STC ezingama-08 kunye nama-40 ukuze isetyenziswe kwisinyithi kunye neplastiki, ngokwahlukeneyo.

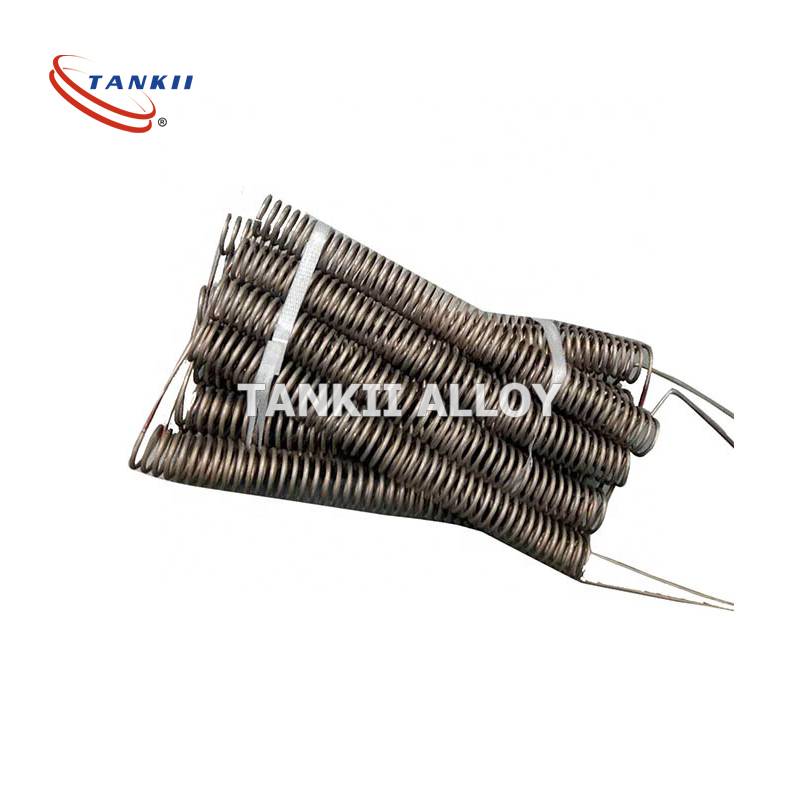

2. Intshayelelo yaseNtwasahlobo kunye nezicelo

Intwasahlobo ejikelezayo, okanye intwasahlobo yeenwele, kwiwotshi ye-alamu.

Intwasahlobo eguquguqukayo. Xa icinezelwe, iikhoyili ziyatyibilika phezu kwezinye, nto leyo evumela ukuba zihambe ixesha elide.

Imithombo yevolute ethe nkqo yetanki yaseStuart

Iispring zoxinzelelo kwisixhobo sokujika esinomgca osongiweyo.

Ibha yokujika ejijekileyo phantsi komthwalo

Intwasahlobo yegqabi kwilori

Iisprings zingahlulwa-hlulwa ngokuxhomekeke kwindlela amandla omthwalo asetyenziswa ngayo kuzo:

Intwasahlobo yoxinzelelo/yolwandiso – intwasahlobo yenzelwe ukusebenza nomthwalo woxinzelelo, ngoko ke intwasahlobo iyolula njengoko umthwalo ufakwa kuyo.

Intwasahlobo yokucinezelwa – yenzelwe ukusebenza ngomthwalo wokucinezelwa, ukuze intwasahlobo ibe mfutshane njengoko umthwalo ufakwa kuyo.

Intwasahlobo yokujika – ngokungafaniyo neentlobo ezingentla apho umthwalo ungamandla ajikelezayo, umthwalo osetyenziswa kwintwasahlobo yokujika yintshukumo okanye amandla okujika, kwaye isiphelo sentwasahlobo sijikeleza nge-engile njengoko umthwalo usetyenziswa.

Umthwalo oxhaswayo wentwasahlobo ohlala uhleli ufana kulo lonke umjikelo wokuphambuka.

Intwasahlobo eguquguqukayo – ukumelana kwekhoyili nomthwalo kuyahluka ngexesha lokucinezelwa.

Intwasahlobo yokuqina eguquguqukayo – ukumelana kwekhoyili xa ilayishwa kunokwahluka ngokuguquguqukayo umzekelo yinkqubo yolawulo, ezinye iintlobo zezi springs nazo ziyahluka ngobude bazo ngaloo ndlela zibonelela nangobuchule bokusebenza.

Zinokwahlulwa ngokwemilo yazo:

Intwasahlobo ethe tyaba – olu hlobo lwenziwe ngentsimbi yentwasahlobo ethe tyaba.

Intwasahlobo ematshinini – olu hlobo lwentwasahlobo lwenziwa nge-machining bar stock ene-lathe kunye/okanye i-milling operation endaweni yokusebenza nge-coiling. Ekubeni imashinini, intwasahlobo inokubandakanya iimpawu ukongeza kwi-elastic element. Intwasahlobo ematshinini inokwenziwa kwiimeko eziqhelekileyo zomthwalo wokucinezelwa/ukwandiswa, i-torsion, njl.njl.

Intwasahlobo yeserpentine – ucingo olugobileyo oluziingceba – isetyenziswa rhoqo kwimpahla/ifenitshala yanamhlanje.

3. Ukwakhiwa kweekhemikhali kunye nePropathi ephambili yeCu-Ni Low Resistance Alloy

| IGrade yeeProperties | I-CuNi1 | I-CuNi2 | I-CuNi6 | I-CuNi8 | I-CuMn3 | I-CuNi10 | |

| Ulwakhiwo oluPhambili lweeKhemikhali | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | I-Bal | I-Bal | I-Bal | I-Bal | I-Bal | I-Bal | |

| Ubushushu obuphezulu beNkonzo eQhubekayo (oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Ukuqina kwakhona kwi-20oC (Ωmm2/m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Uxinano (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| Ukuqhuba kwe-Thermal (α×10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Amandla okuThamba (i-Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| I-EMF vs Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Indawo yokunyibilika eqikelelweyo (oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Ulwakhiwo lweMicrographic | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | |

| Ipropati yeMagnetic | akukho | akukho | akukho | akukho | akukho | akukho | |

| IGrade yeeProperties | I-CuNi14 | I-CuNi19 | I-CuNi23 | I-CuNi30 | I-CuNi34 | I-CuNi44 | |

| Ulwakhiwo oluPhambili lweeKhemikhali | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | I-Bal | I-Bal | I-Bal | I-Bal | I-Bal | I-Bal | |

| Ubushushu obuphezulu beNkonzo eQhubekayo (oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| Ukuqina kwakhona kwi-20oC (Ωmm2/m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Uxinano (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Ukuqhuba kwe-Thermal (α×10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Amandla okuThamba (i-Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| I-EMF vs Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Indawo yokunyibilika eqikelelweyo (oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Ulwakhiwo lweMicrographic | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | |

| Ipropati yeMagnetic | akukho | akukho | akukho | akukho | akukho | akukho | |

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu