Wamkelekile kwiwebhusayithi zethu!

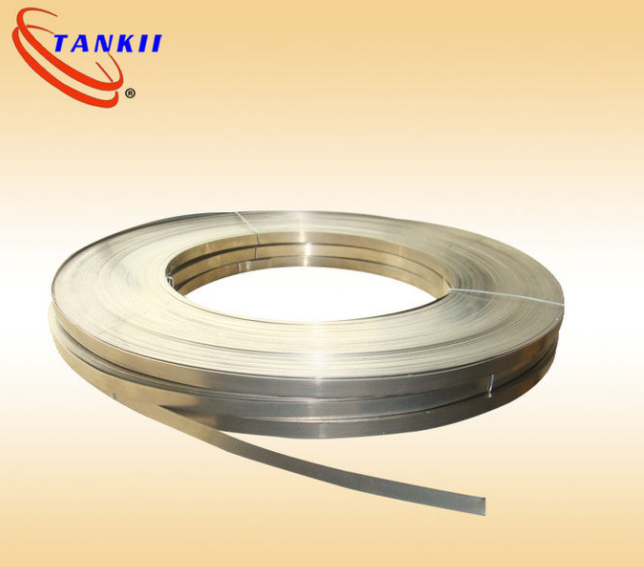

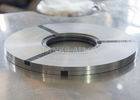

IiResistors eziKhazimlayo eziSicaba 5mm Ububanzi 1Cr13Al4 FeCrAl ucingo lokumelana

I-1Cr13Al4 FeCrAl alloy Bright Flat Strip/ Wide Strip yokusetyenziswa kweResistors

IiFecral Alloys kunye neeNickel-chromium alloys zikhethwe ukuba zibe zizinto ezikhuselayo kwi-resistor efakwe kuba ii-nickel-chromium alloys zine-electrical resistivity ephezulu esetyenziswa kakhulu kwi-thin film resistors [1, 2]. Ukumelana kweshiti kwefilimu ye-nickel-chrome alloy equlethe i-20% chromium kunokuba phezulu njenge-2-3 kilo ohms kwaye kusagcinwe uzinzo oluhle. I-temperature coefficient 1 of resistance (TCR) ye-bulk nickel-chrome alloy imalunga ne-110 ppm/°C. Ngokudibanisa inani elincinci le-silicon kunye ne-aluminium kunye ne-nickel-chromium, uzinzo lobushushu luphuculwa ngakumbi.

Isicelo:

Iiresistor ezifakwe kwibhodi yocingo eprintiweyo ziya kuba luncedo ekwenzeni iipakethe zibe ncinci ngokuthembeka okuphezulu kunye nokusebenza kombane okuphuculweyo. Ukudibanisa ukusebenza kweresistor kwi-substrate ye-laminate kukhulula indawo yomphezulu we-PWB esetyenziswa zizinto ezihlukeneyo, okuvumela ukusebenza kwesixhobo okwandisiweyo ngokubekwa kwezinto ezisebenzayo ngakumbi. Ii-alloy ze-nickel-chromium zinokumelana okuphezulu kombane, okwenza ukuba zibe luncedo ekusebenziseni kwiintlobo ngeentlobo zezicelo. I-nickel kunye ne-chromium zixutywe nge-silicon kunye ne-aluminium ukuphucula uzinzo lobushushu kunye nokunciphisa i-coefficient yobushushu yokumelana. Umaleko omncinci wefilimu osekelwe kwi-alloy ze-nickel-chromium ubekwe rhoqo kwimiqulu yefoyile yobhedu ukwenza izinto zokusetyenziswa kwe-resistor efakwe ngaphakathi. Umaleko omncinci wefilimu oncitshisiweyo phakathi kobhedu kunye ne-laminate unokunqunyulwa ngokukhetha ukwenza iiresistor ezihlukeneyo. Iikhemikhali zokunqunyulwa zixhaphakile kwiinkqubo zemveliso ye-PWB. Ngokulawula ubukhulu bee-alloy, amaxabiso okumelana neshiti ukusuka kwi-25 ukuya kwi-250 ohm/sq. afunyanwa. Eli phepha liza kuthelekisa izinto ezimbini ze-nickel-chromium kwiindlela zazo zokugrumba, ukufana, ukuphathwa kwamandla, ukusebenza kobushushu, ukunamathela kunye nesisombululo sokugrumba.

Iiresistor ezifakwe kwibhodi yocingo eprintiweyo ziya kuba luncedo ekwenzeni iipakethe zibe ncinci ngokuthembeka okuphezulu kunye nokusebenza kombane okuphuculweyo. Ukudibanisa ukusebenza kweresistor kwi-substrate ye-laminate kukhulula indawo yomphezulu we-PWB esetyenziswa zizinto ezihlukeneyo, okuvumela ukusebenza kwesixhobo okwandisiweyo ngokubekwa kwezinto ezisebenzayo ngakumbi. Ii-alloy ze-nickel-chromium zinokumelana okuphezulu kombane, okwenza ukuba zibe luncedo ekusebenziseni kwiintlobo ngeentlobo zezicelo. I-nickel kunye ne-chromium zixutywe nge-silicon kunye ne-aluminium ukuphucula uzinzo lobushushu kunye nokunciphisa i-coefficient yobushushu yokumelana. Umaleko omncinci wefilimu osekelwe kwi-alloy ze-nickel-chromium ubekwe rhoqo kwimiqulu yefoyile yobhedu ukwenza izinto zokusetyenziswa kwe-resistor efakwe ngaphakathi. Umaleko omncinci wefilimu oncitshisiweyo phakathi kobhedu kunye ne-laminate unokunqunyulwa ngokukhetha ukwenza iiresistor ezihlukeneyo. Iikhemikhali zokunqunyulwa zixhaphakile kwiinkqubo zemveliso ye-PWB. Ngokulawula ubukhulu bee-alloy, amaxabiso okumelana neshiti ukusuka kwi-25 ukuya kwi-250 ohm/sq. afunyanwa. Eli phepha liza kuthelekisa izinto ezimbini ze-nickel-chromium kwiindlela zazo zokugrumba, ukufana, ukuphathwa kwamandla, ukusebenza kobushushu, ukunamathela kunye nesisombululo sokugrumba.

Izinto ze-alloy

olunye uthotho lwemveliso:

I-FeCrAl Alloy: OCr15Al5,1Cr13Al4, 0Cr21Al4, 0Cr19Al3, 0Cr21Al6, 0Cr25Al5, 0Cr21Al6Nb, 0Cr27Al7Mo2.

I-NiCr Alloy: Cr20Ni80,Cr30Ni70,Cr20Ni35,Cr20Ni30,Cr15Ni60.

CuNi Ingxubevange: NC003,NC010,NC012,NC015,NC020,NC025,NC030,NC040,NC050,Constantan,6J8/11/12/13/.

Intambo yokuwelda: ERNiCrMo-3/4/13,ERNiCrFe-3/7,ERNiCr-3/7,ERNiCu-7,ERNi-1, ER70S-6.

I-alloy ye-thermocouple: K,J,E,T,N, S,R,B,KX,JX,EX,TX,NX.

I-alloy ye-Inconel: Inconel 600,601,617,X-750,625,690,718,825.

I-alloy ye-Incoloy: I-Incoloy 800,800H,800HT,825,925.

I-Hastelloy alloy: HC-276,C-22,C-4,HB,B/2/3,X,N.

I-Monel Alloy: I-Monel 400,K500.

I-alloy enobushushu obuphezulu: A-286,Nimonic80A/90,GH131,GH1140,GH36,GH2706,GH2901,GH3625,GH3536,GH4169.

Uthotho lwe-alloy echanekileyo: 1J33,3J01,3J9,4J29,4J32.4J33,Invar36,4J45.FeNi50.

I-alloy yokutshiza ngobushushu: Inconel 625,Ni95Al5,Monel400,45CT,HC-276,K500,Cr20Ni80.

olunye uthotho lwemveliso:

I-FeCrAl Alloy: OCr15Al5,1Cr13Al4, 0Cr21Al4, 0Cr19Al3, 0Cr21Al6, 0Cr25Al5, 0Cr21Al6Nb, 0Cr27Al7Mo2.

I-NiCr Alloy: Cr20Ni80,Cr30Ni70,Cr20Ni35,Cr20Ni30,Cr15Ni60.

CuNi Ingxubevange: NC003,NC010,NC012,NC015,NC020,NC025,NC030,NC040,NC050,Constantan,6J8/11/12/13/.

Intambo yokuwelda: ERNiCrMo-3/4/13,ERNiCrFe-3/7,ERNiCr-3/7,ERNiCu-7,ERNi-1, ER70S-6.

I-alloy ye-thermocouple: K,J,E,T,N, S,R,B,KX,JX,EX,TX,NX.

I-alloy ye-Inconel: Inconel 600,601,617,X-750,625,690,718,825.

I-alloy ye-Incoloy: I-Incoloy 800,800H,800HT,825,925.

I-Hastelloy alloy: HC-276,C-22,C-4,HB,B/2/3,X,N.

I-Monel Alloy: I-Monel 400,K500.

I-alloy enobushushu obuphezulu: A-286,Nimonic80A/90,GH131,GH1140,GH36,GH2706,GH2901,GH3625,GH3536,GH4169.

Uthotho lwe-alloy echanekileyo: 1J33,3J01,3J9,4J29,4J32.4J33,Invar36,4J45.FeNi50.

I-alloy yokutshiza ngobushushu: Inconel 625,Ni95Al5,Monel400,45CT,HC-276,K500,Cr20Ni80.

Bhala umyalezo wakho apha uze uwuthumele kuthi

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu