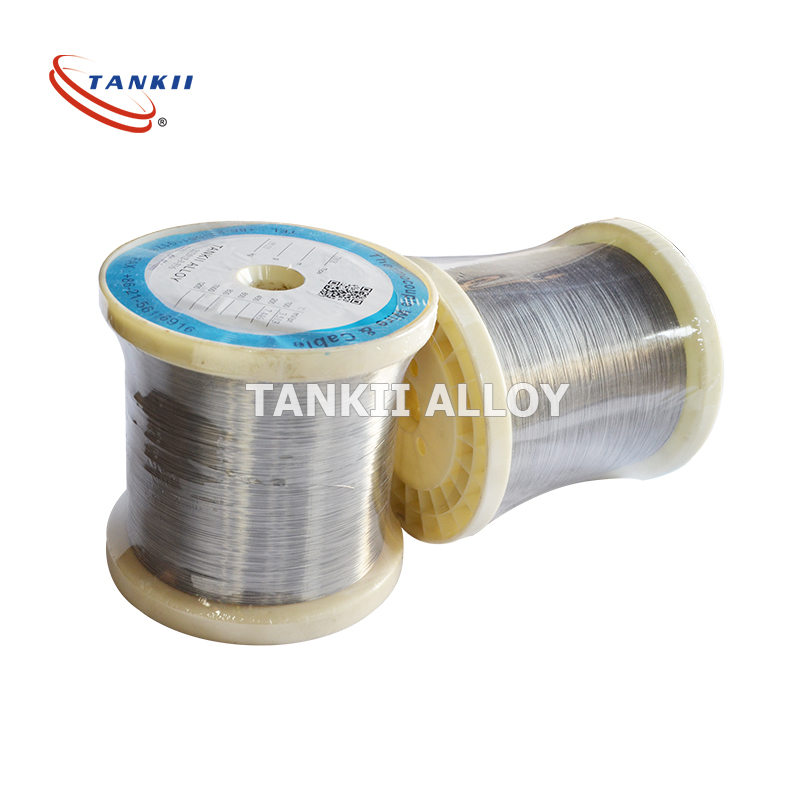

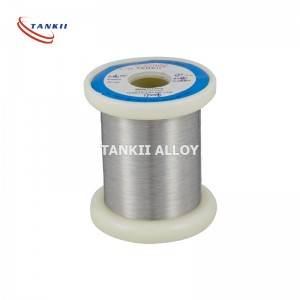

I-Radiator Resistant Heat Wire 0cr25al5 Alloy Wire I-Fecral resistant wire

I-Radiator Resistance Heating Wire Fecral 0cr25al5 Alloy Ngombala wesilivere ongwevu

1. Inkcazo eneenkcukacha

I-FeCrAl Alloy, 1Cr13Al4,0Cr23Al5, 0Cr25Al5, 0Cr20Al6RE, 0Cr21Al6Nb, 0Cr27Al7Mo2

I-FeCrAl Alloy yi-ferritic iron-chromium-aluminium alloy (i-FeCrAl alloy) esetyenziswa kwiinkqubo zokutshiza i-arc kunye ne-flame. Le alloy ivelisa iingubo ezixineneyo nezibopha kakuhle, ezimelana ne-oxidation kunye nokugqwala kumaqondo obushushu aphezulu.

Ukusetyenziswa okanye iiPropati: Intambo yokutshiza enamandla okubopha agqwesileyo. Iileya ezitshiziweyo zale nto azikwazi ukumelana nokuguquguquka kumaqondo obushushu aphezulu kwaye zisetyenziswa njengomaleko we-buffer kuzo zonke ezinye ii-alloys zokutshiza.

0Cr25Al5

I-0Cr25Al5 yi-ferritic iron-chromium-aluminium alloy (i-FeCrAl alloy) esetyenziswa kwiinkqubo zokutshiza i-arc kunye nelangatye. Le ngxubevange ivelisa iingubo ezixineneyo nezibopha kakuhle, ezimelana ne-oxidation kunye nokugqwala kumaqondo obushushu aphezulu.

2. Iipropati zoomatshini

| Ubushushu beNkonzo eQhubekayo obuphezulu | 980ºC |

| Ukuqina kwakhona kwi-20ºC | 1.28 ohm mm2/m |

| Uxinano | 7.4 g/cm3 |

| Ukuqhuba kweThermal | 52.7 KJ/m@h@ºC |

| I-Coefficient yoKwandiswa koBushushu | 15.4×10-6/ºC |

| Indawo yokunyibilika | 1450ºC |

| Tensile strength | 637~784 Mpa |

| Ukwandiswa | Ubuncinci be-12% |

| Utshintsho lweCandelo Isantya sokuNciphisa | 65~75% |

| Ukugoba Ngokuphindaphindiweyo | Ubuncinane amaxesha ama-5 |

| Ixesha leNkonzo eliQhubekekayo | - |

| Ukuqina | 200-260HB |

| Ulwakhiwo lweMicrographic | I-Ferrite |

| Ipropati yeMagnetic | Imagnethi |

3. Iimpawu

Ukusebenza okuzinzileyo; Ukuchasana ne-oxidation; Ukumelana nokugqwala; I-coefficient yokwandiswa ephantsi; Uzinzo lobushushu obuphezulu; Amandla amahle okwenza ikhoyili; Umthwalo ophezulu womphezulu; Imeko efanayo kwaye intle yomphezulu engenamabala

4. Iimveliso kunye neenkonzo

1). Ipasi: Isatifikethi se-ISO9001, kunye nesatifikethi se-SO14001;

2). Iinkonzo zokuhlawula emva kokuthengisa;

3). Iodolo encinci yamkelwe;

4). Iipropati ezizinzileyo kubushushu obuphezulu;

5). Ukuhanjiswa ngokukhawuleza.

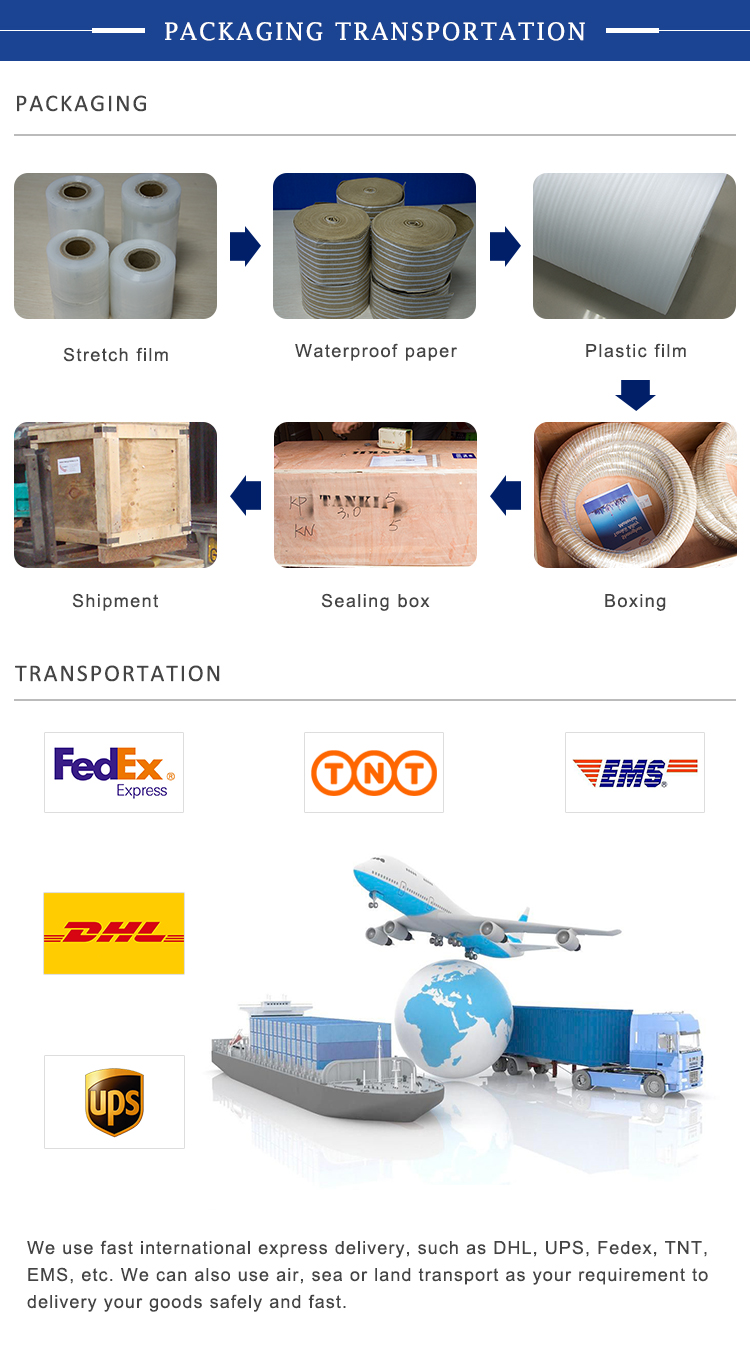

6). I-Spool, ikhoyili, ibhokisi, ibhokisi yomthi enefilimu yeplastiki okanye elinye iphepha lokusonga ngokweemfuno zomthengi.

5. Isici sobushushu sokuxhathisa umbane

| 20ºC | 100ºC | 200ºC | 300ºC | 400ºC | 500ºC | 600ºC | 700ºC | 800ºC | 900ºC | 1000ºC |

| 1 | 1.005 | 1.014 | 1.028 | 1.044 | 1.064 | 1.090 | 1.120 | 1.132 | 1.142 | 1.150 |

6. Ukwakheka kweekhemikhali

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Okunye | ||

| Ubuninzi | |||||||||||

| 0.12 | 0.025 | 0.025 | 0.70 | Ubuninzi 1.0 | 13.0~15.0 | Ubuninzi 0.60 | 4.5~6.0 | Ibhala. | - | ||

Ukuba unomdla, nceda ungathandabuzi ukuqhagamshelana nathi.

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu