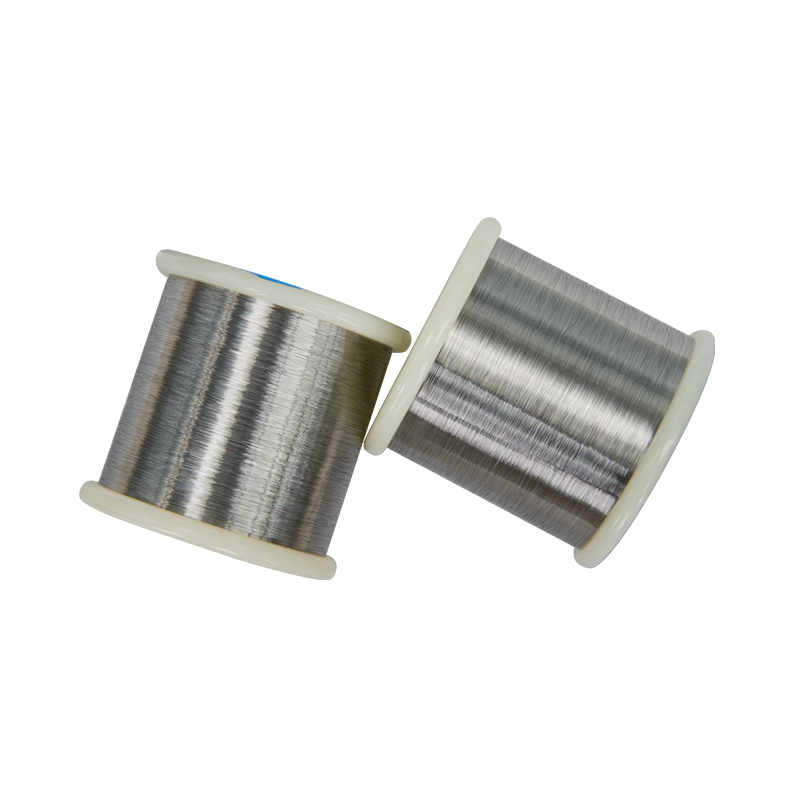

I-Nife52/Feni52/Alloy 52 Fe-Ni Constant Expansion Alloy Tube wire yeSealing Material ye-Sealing Material

I-Alloy 52 Iqulethe i-nickel engama-52% kunye ne-48% yentsimbi kwaye isetyenziswa kakhulu kushishino lonxibelelwano. Ikwasetyenziswa nakwiindidi ezahlukeneyo zezicelo ze-elektroniki, ingakumbi kwizitywino zeglasi.

I-Alloy 52 yenye yee-alloy zokutywina iglasi ukuya kwisinyithi ezenzelwe ukusetyenziswa kwiindidi ngeendidi zeeglasi ezithambileyo. Yaziwa ngomlinganiselo wokwanda kobushushu ophantse ungaguquguquki ukuya kuthi ga kwi-1050F (565 C).

Uluhlu Lobukhulu:

*Iphepha—Ubukhulu 0.1mm ~ 40.0mm, ububanzi: ≤300mm, Imeko: iqengqeleke ngokubandayo (ishushu), ikhanya, igqunyiwe ngokukhanyayo

*Intambo Ejikelezayo—Ububanzi obuyi-0.1mm~Ububanzi obuyi-5.0mm, Imeko: itsaliwe kubanda, ikhanya, igqunyiwe kakuhle

*Intambo Ethe tyaba—Umda 0.5mm ~Umda 5.0mm, ubude: ≤1000mm, Imeko: igobile ngokucaba, igqunyiwe ngokukhanyayo

*Ibhari—Ububanzi obuyi-5.0mm ~ Ububanzi obuyi-8.0mm, ubude: ≤2000mm, Imeko: itsaliwe kubanda, ikhanya, icwebezelayo

Ububanzi obuyi-8.0mm ~ Ububanzi obuyi-32.0mm, ubude: ≤2500mm, Imeko: ishushu iqengqelekile, ikhanya, icwebezelayo

Ububanzi obuyi-32.0mm ~ Ububanzi obuyi-180.0mm, ubude: ≤1300mm, Imeko: ishushu, ixotyulwe, ijikwe, ishushu iphathwe

*I-Capillary—OD 8.0mm~1.0mm,ID 0.1mm~8.0mm,ubude:≤2500mm,Imeko: itsaliwe kubanda, ikhanya, igqunyiwe kakuhle.

*Ipayipi—OD 120mm~8.0mm,ID 8.0mm~129mm,ubude:≤4000mm,Imeko: itsaliwe kubanda, ikhanya, iqhotsiweyo kakuhle.

Ikhemistri:

| Cr | Al | C | Fe | Mn | Si | P | S | Ni | Mg | |

| Ubuncinci | – | – | – | – | – | – | – | – | 50.5 | – |

| Ubuninzi | 0.25 | 0.10 | 0.05 | Ibhala. | 0.60 | 0.30 | 0.025 | 0.025 | – | 0.5 |

I-Avareji ye-Linear Expansion Coefficient:

| Ibanga | α1/10-6ºC-1 | |||||||

| 20~100ºC | 20~200ºC | 20~300ºC | 20~350ºC | 20~400ºC | 20~450ºC | 20~500ºC | 20~600ºC | |

| 4J52 | 10.3 | 10.4 | 10.2 | 10.3 | 10.3 | 10.3 | 10.3 | 10.8 |

Iipropati:

| Imeko | Amandla okuxinana aqikelelwayo | Ubushushu obuqhelekileyo bokusebenza | ||

| N/mm² | ksi | °C | °F | |

| I-Annealed | 450 – 550 | 65 – 80 | ukuya kuthi ga kwi +450 | ukuya kuthi ga kwi +840 |

| Itsalwe Kanzima | 700 – 900 | 102 – 131 | ukuya kuthi ga kwi +450 | ukuya kuthi ga kwi +840 |

| Ukwenziwa: |

| I-alloy inamandla okuguquguquka kwaye inokwenziwa ngeendlela eziqhelekileyo. |

| Ukuwelda: |

| Ukuwelda ngeendlela eziqhelekileyo kufanelekile kule alloy. |

| Unyango lobushushu: |

| I-alloy 52 kufuneka ifakwe kwi-1500F ilandelwe kukupholisa umoya. Ukunciphisa uxinzelelo oluphakathi kungenziwa kwi-1000F. |

| Ukwenziwa: |

| Ukubumba kufanele kwenziwe kubushushu obuyi-2150 F. |

| Ukusebenza Ngobandayo: |

| Ingxubevange ilula ukuyisebenzisa kubanda. Umgangatho wokuzoba onzulu kufuneka uchazwe kuloo msebenzi wokwakha kunye nomgangatho ofakwe kwi-anneal wokwakha ngokubanzi. |

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu