Impumelelo enkulu yeshishini leenqwelo-moya ayinakwahlulwa kuphuhliso kunye nophuhliso kwitekhnoloji yezixhobo zeenqwelo-moya. Ukuphakama okuphezulu, isantya esiphezulu kunye nokukwazi ukuqhuba kakuhle kweenqwelo-moya kufuna ukuba izixhobo zesakhiwo senqwelo-moya ziqinisekise amandla aneleyo kunye neemfuno zokuqina. Izixhobo zenjini kufuneka zanelise imfuno yokumelana nobushushu obuphezulu, ii-alloys zobushushu obuphezulu, izixhobo ezidityanisiweyo ezisekwe kwi-ceramic zezona zinto ziphambili.

Intsimbi eqhelekileyo ithambisa ngaphezu kwama-300℃, nto leyo eyenza ukuba ingafaneleki kwiindawo ezinobushushu obuphezulu. Ekufuneni ukusebenza kakuhle kokuguqulwa kwamandla, kufuneka amaqondo obushushu aphezulu naphezulu okusebenza kwicandelo lamandla enjini yobushushu. Ii-alloys ezinobushushu obuphezulu zenzelwe ukusebenza ngokuzinzileyo kumaqondo obushushu angaphezu kwama-600℃, kwaye ubuchwepheshe buyaqhubeka nokukhula.

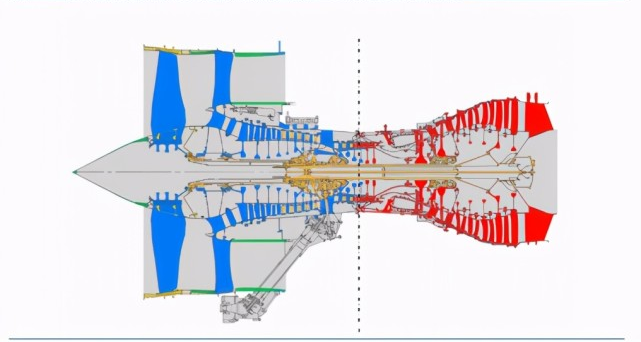

Ii-alloys ezinobushushu obuphezulu zizinto ezibalulekileyo kwiinjini zeenqwelo moya, ezahlulwe zibe zii-alloys ezisekelwe kwisinyithi ezinobushushu obuphezulu, ezisekelwe kwi-nickel zizinto eziphambili ze-alloy. Ii-alloys ezinobushushu obuphezulu zisetyenziswe kwiinjini zeenqwelo moya ukusukela ekuqaleni kwazo, kwaye zizinto ezibalulekileyo ekwenziweni kweenjini zeenqwelo moya. Inqanaba lokusebenza kwenjini lixhomekeke kakhulu kwinqanaba lokusebenza kwezinto ze-alloy ezinobushushu obuphezulu. Kwiinjini zeenqwelo moya zanamhlanje, ubungakanani bezinto ze-alloy ezinobushushu obuphezulu bufikelela kuma-40-60 ekhulwini obunzima benjini iyonke, kwaye zisetyenziswa kakhulu kwiindawo ezine eziphambili ezishushu: iindawo zokutsha, izikhokelo, ii-turbine blades kunye neediski ze-turbine, kwaye ukongeza, isetyenziselwa izinto ezifana neemagazini, iiringi, iindawo zokutshaja kunye nee-nozzles zomsila.

(Inxalenye ebomvu yomzobo ibonisa ii-alloys zobushushu obuphezulu)

Iialloy ezisekwe kwi-nickel ezinobushushu obuphezulu ngokubanzi isebenza kwi-600 ℃ ngaphezulu kweemeko zoxinzelelo oluthile, ayinayo nje kuphela i-oxidation entle yobushushu obuphezulu kunye nokumelana nokugqwala, kwaye inamandla aphezulu obushushu obuphezulu, amandla okuhamba kunye namandla okunyamezela, kunye nokumelana okuhle kokudinwa. Isetyenziswa kakhulu kwicandelo leenqwelo-moya kunye neenqwelo-moya phantsi kweemeko zobushushu obuphezulu, izinto zokwakha, ezifana neebhlade zeenjini zeenqwelo-moya, iidiski ze-turbine, amagumbi okutsha njalo njalo. Ii-alloys ezisekwe kwi-nickel ezinobushushu obuphezulu zinokwahlulwa zibe zii-alloys eziguquguqukayo zobushushu obuphezulu, ii-alloys ezifakwe kwi-cast high-temperature kunye nee-alloys ezintsha zobushushu obuphezulu ngokwenkqubo yokuvelisa.

Xa ubushushu bokusebenza kwe-alloy engatshisi ubushushu buphezulu, izinto eziqinisayo kwi-alloy ziyanda, kokukhona ukwakheka kwayo kuyinkimbinkimbi, nto leyo ebangela ukuba ezinye ii-alloy zingasetyenziswa kuphela kwimeko ye-cast, azinakuguqulwa zibe yi-hot processing. Ngaphezu koko, ukwanda kwezinto ezidibanisa i-alloy kwenza ii-alloy ezisekelwe kwi-nickel ziqine ngokwahlukana okukhulu kwee-compounds, nto leyo ebangela ukungahambelani kakuhle kwe-organization kunye ne-properties.Ukusetyenziswa kwenkqubo yokunyibilikisa isinyithi somgubo ukuvelisa ii-alloys ezinobushushu obuphezulu, kunokusombulula ezi ngxaki zingasentla.Ngenxa yamasuntswana amancinci e-powder, isantya sokupholisa i-powder, ukuphelisa ukwahlulwahlulwa, ukuphucula ukusebenza okushushu, i-alloy yokuqala yokuphosa ibe yi-eshushu esebenza kakuhle ye-alloys yobushushu obuphezulu, amandla okuvelisa kunye neempawu zokudinwa ziyaphucuka, i-alloy yobushushu obuphezulu yomgubo yokuvelisa i-alloys enamandla aphezulu ivelise indlela entsha.

Ixesha leposi: Jan-19-2024