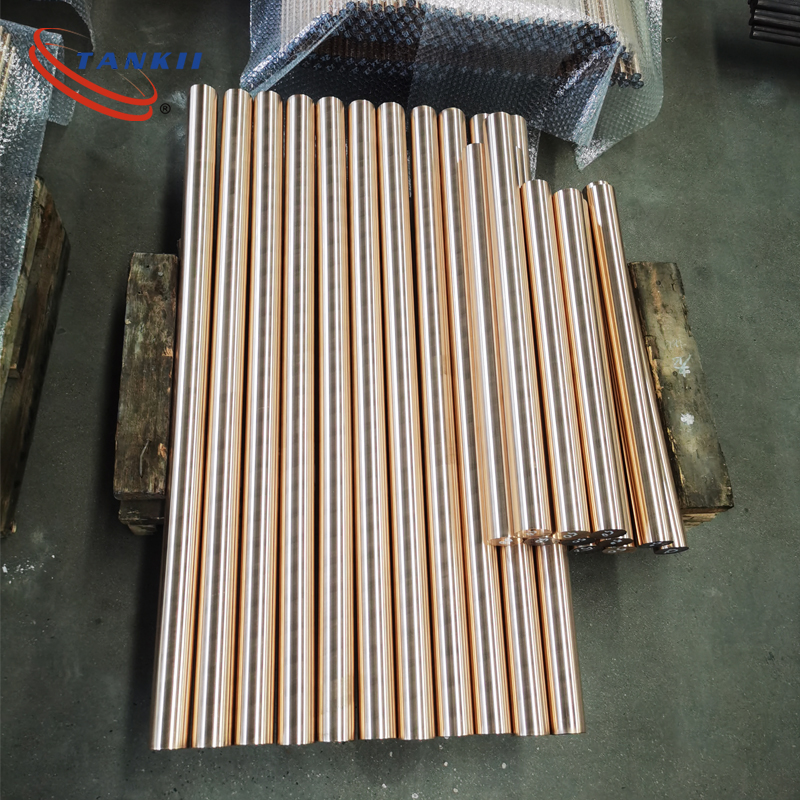

I-Inconel Alloy 625 718 600 Wire Uns N06625 Fine/ Filler/ Welding Wires

I-Inconel yintsapho yee-super alloys ezisekelwe kwi-nickel chromium e-austenitic.

Ii-alloys ze-Inconel zizixhobo zokumelana ne-oxidation corrion ezifanelekileyo kakhulu kwinkonzo kwiindawo ezixineneyo eziphantsi koxinzelelo kunye

ubushushu. Xa ishushu, i-Inconel yenza umaleko we-oxide oqinileyo, ohlala uhleli, okhusela umphezulu ekuhlaselweni ngakumbi. I-Inconel igcina

amandla kuluhlu olubanzi lobushushu, inomtsalane kwizicelo zobushushu obuphezulu apho i-aluminium kunye nentsimbi ziya kuphelelwa ngamandla

ngenxa yezithuba zekristale ezibangelwa bubushushu. Amandla aphezulu obushushu e-Inconel aphuhliswa sisisombululo esiqinileyo

ukuqina okanye ukuqina kwemvula, kuxhomekeke kwi-alloy.

I-Inconel 718 yi-alloy ye-nickel-chromium-molybdenum eyenzelwe ukumelana noluhlu olubanzi lweendawo ezinobungozi kakhulu, ukubola kwemigodi kunye nokuqhekeka kwe-cravice. Le alloy yentsimbi ye-nickel ikwabonisa iipropati eziphezulu kakhulu zemveliso, ukuxinana, kunye nokuqhekeka kwiqondo lobushushu eliphezulu. Le alloy ye-nickel isetyenziswa ukusuka kumaqondo obushushu aqinileyo ukuya kuthi ga kwinkonzo yexesha elide kwi-1200° F. Enye yeempawu ezahlulayo zokwakheka kwe-Inconel 718 kukongeza i-niobium ukuvumela ukuqina kobudala okuvumela ukuqhobosheka kunye nokuwelda ngaphandle kokuqina okuzenzekelayo ngexesha lokufudumeza nokuphola. Ukongezwa kwe-niobium kusebenza ne-molybdenum ukuqinisa i-matrix ye-alloy kunye nokubonelela ngamandla aphezulu ngaphandle konyango lobushushu oluqinisiweyo. Ezinye ii-alloy ze-nickel-chromium ezidumileyo ziqiniswa ngokuguga ngokongezwa kwe-aluminium kunye ne-titanium. Le alloy yentsimbi ye-nickel yenziwe ngokulula kwaye inokudityaniswa kwimeko eqinileyo ye-annealed okanye yemvula (ubudala). Le superalloy isetyenziswa kumashishini ahlukeneyo afana ne-aerospace, i-chemical processing, i-marine engineering, izixhobo zokulawula ungcoliseko, kunye nee-reactors zenyukliya.

Izinto ezisetyenziswa kubushushu obuphezulu, ezinje ngee-turbine blades, ii-guide vanes, ii-turbine disks, ii-compressor disks zoxinzelelo oluphezulu, ukwenziwa koomatshini kunye namagumbi okutsha asetyenziswa ekwenziweni kwee-aircraft, ii-naval kunye nee-industrial gas turbines.

| Into | I-Inconel 600 | Inconel | Inconel 617 | Inconel | Inconel | Inconel | Inconel | |

| 601 | 690 | 718 | X750 | 825 | ||||

| C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

| Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

| Fe | 6~10 | ukuphumla | ≤3 | ukuphumla | 7~11 | ukuphumla | 5~9 | ≥22 |

| P | ≤0.015 | ≤0.02 | ≤0.015 | – | – | – | – | – |

| S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

| Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

| Cu | ≤0.5 | ≤1 | – | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

| Ni | ≥7.2 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

| Co | – | – | 10~15 | ≤10 | – | ≤1 | ≤1 | – |

| Al | – | 1-1.7 | 0.8-1.5 | ≤0.8 | – | 0.2-0.8 | 0.4-1 | ≤0.2 |

| Ti | – | – | ≤0.6 | ≤1.15 | – | – | 2.25-2.75 | 0.6-1.2 |

| Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

| Nb+Ta | – | – | – | 4.75-5.5 | – | 4.75-5.5 | 0.7-1.2 | – |

| Mo | – | – | 8~10 | 2.8-3.3 | – | 2.8-3.3 | – | 2.5-3.5 |

| B | – | – | ≤0.006 | – | – | – | – | – |

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu