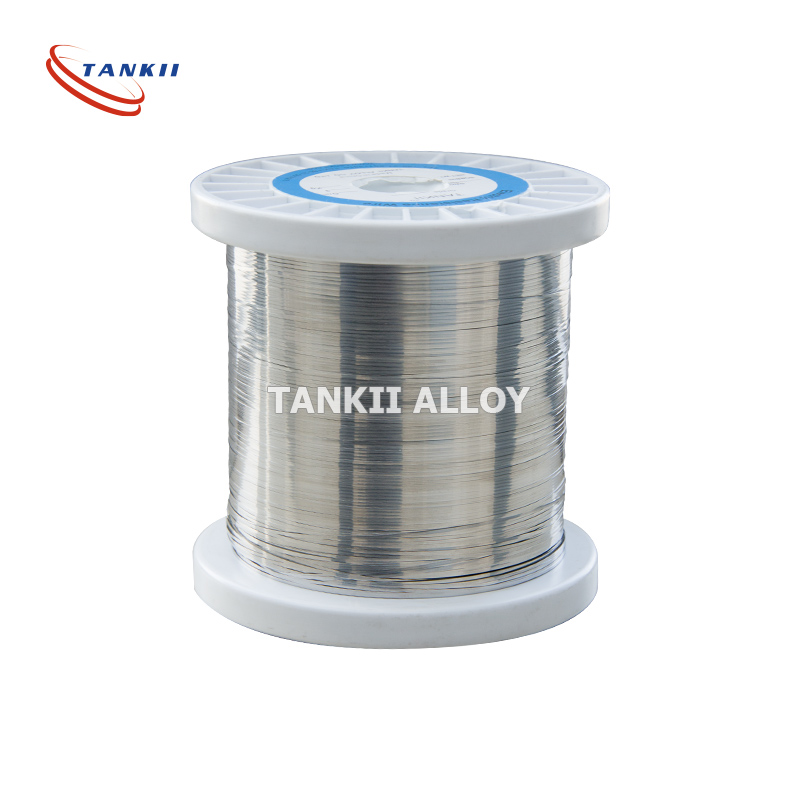

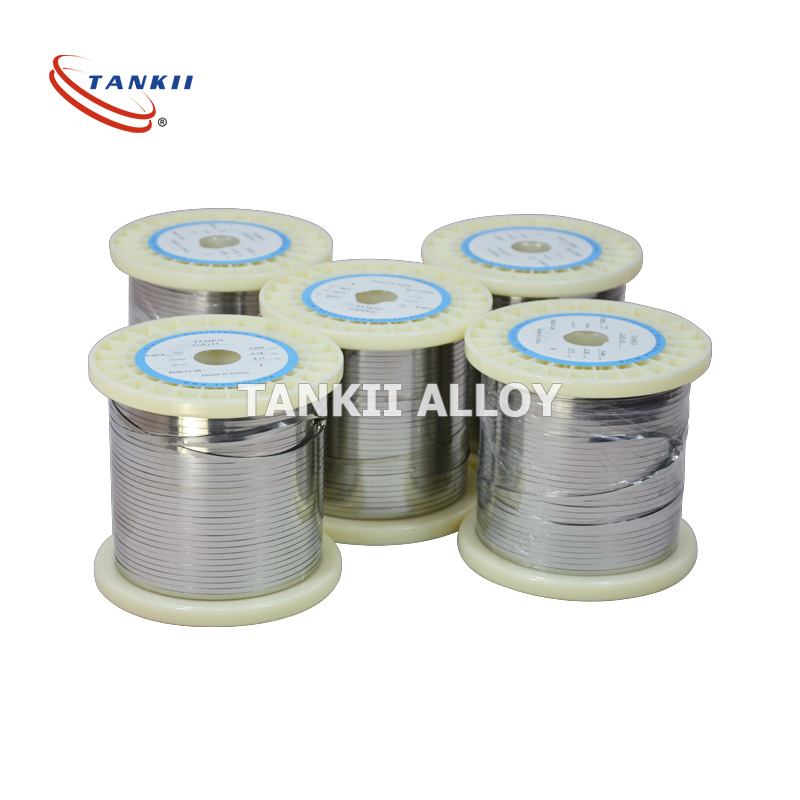

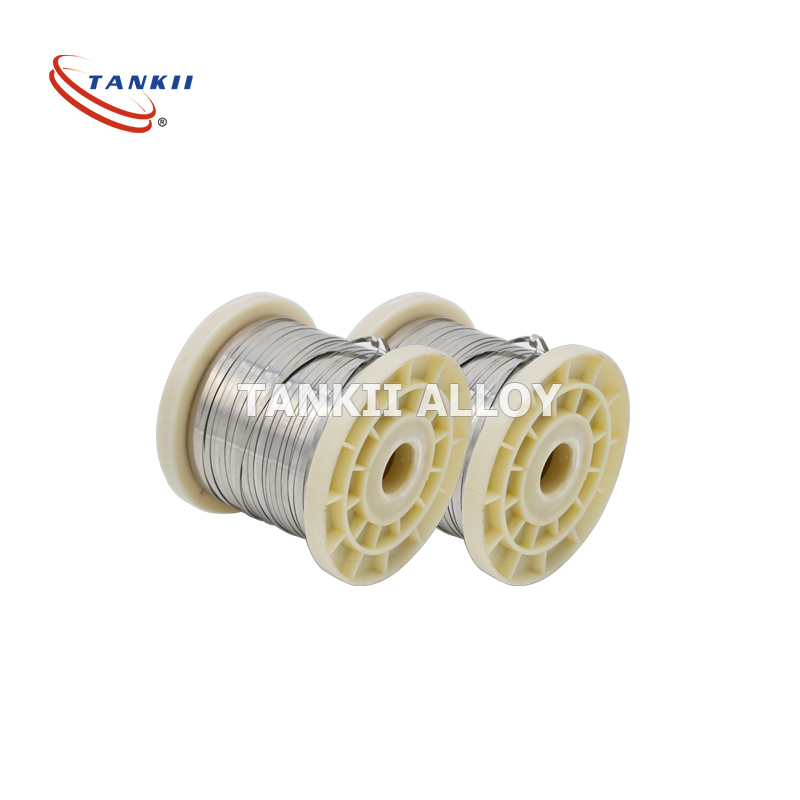

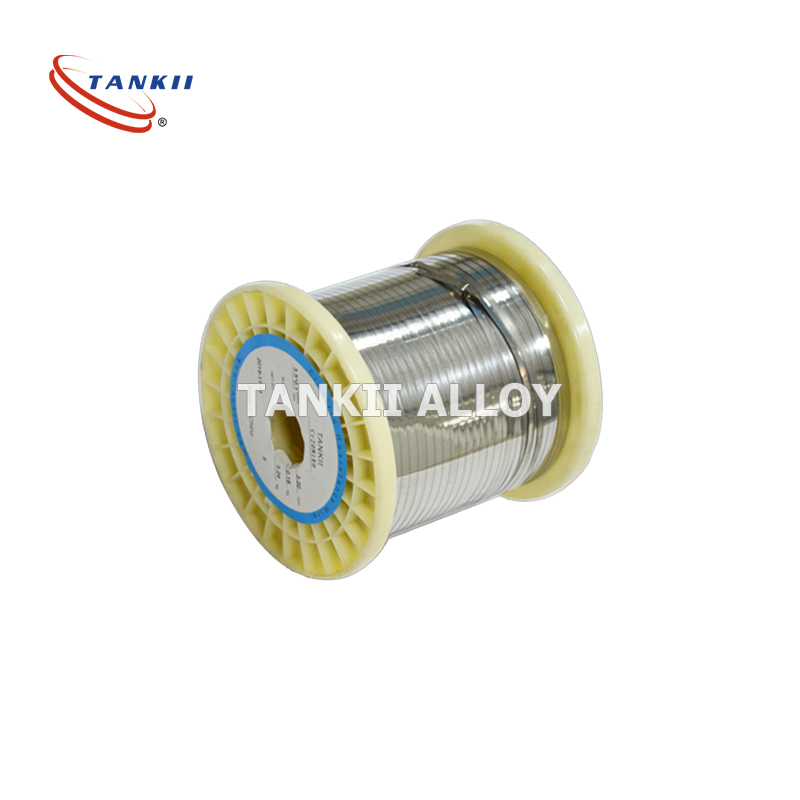

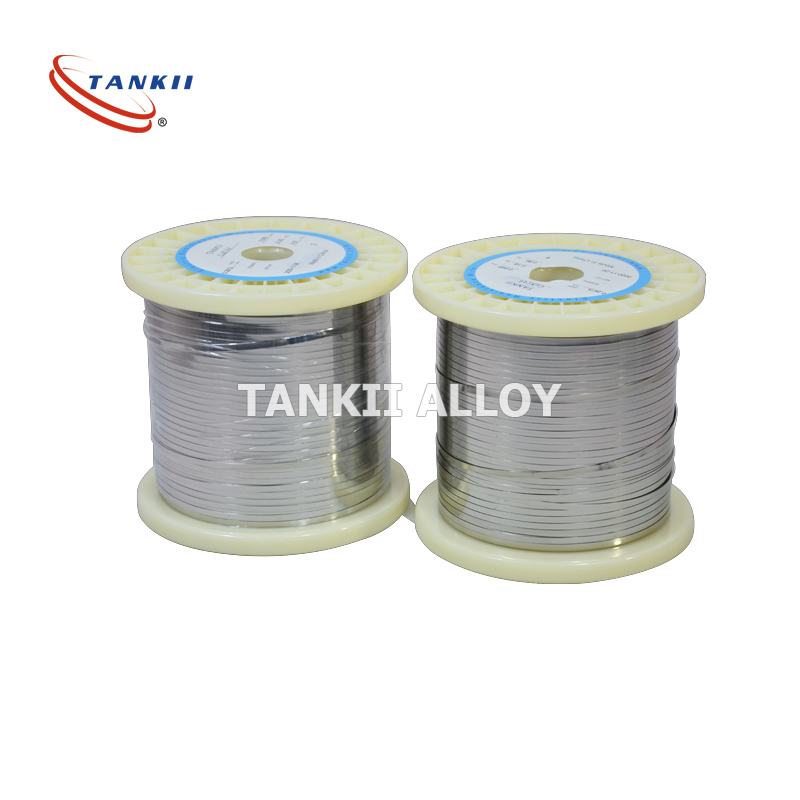

I-Hai-Nicr70 Flat Wire ye-Double Strip Coils Braking Resistor

Ucingo oluSicaba lweHai-Nicr70ngenxaIikhoyili zeStrip eziphindwe kabini Isithinteli sokuQhekeza

I-Ni70Cr30yi-alloy ye-nickel-chromium (i-NiCr alloy) ephawulwa ngokuxhathisa okuphezulu, ukumelana okuhle kwe-oxidation kunye nozinzo oluhle kakhulu kwimo. Ifanelekile ukusetyenziswa kumaqondo obushushu afikelela kwi-1250°C, kwaye igcina ubomi benkonzo obuphezulu xa ithelekiswa nee-alloy ze-Iron chromium alumium.

Izicelo eziqhelekileyo zeI-Ni70Cr30zii-elements zokufudumeza ngombane kwizixhobo zasekhaya, ii-ovens zoshishino kunye nee-resistor (ii-resistors ze-wirewound, ii-resistors zefilimu yesinyithi), ii-flat irons, ii-ayina oomatshini, ii-water heaters, ii-plastic molding dies, ii-soldering irons, ii-metal sheathed tubular elements kunye nee-cartridge elements.

Ulwakhiwo oluqhelekileyo%

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Okunye |

| Ubuninzi | |||||||||

| 0.03 | 0.02 | 0.015 | 0.60 | 0.75~1.60 | 28.0~31.0 | Ibhala. | Ubuninzi 0.50 | Ubuninzi 1.0 | - |

Iimpawu eziqhelekileyo zomzimba

| Ubuninzi (g/cm3) | 8.1 |

| Ukumelana kombane kwi-20ºC(mm2/m) | 1.18 |

| I-coefficient yokwandiswa kobushushu | |

| Ubushushu | I-Coefficient yoKwandiswa koBushushu x10-6/ºC |

| 20 ºC- 1000ºC | 17 |

| Umthamo othile wobushushu | |

| Ubushushu | 20ºC |

| I-J/gK | 0.46 |

| Iqondo lokunyibilika (ºC) | 1380 |

| Ubushushu obuphezulu bokusebenza obuqhubekayo emoyeni (ºC) | 1250 |

| Iimpawu zeMagnetic | okungekho magnethi |

| Izinto Ezichaphazela Ubushushu Bokumelana Nombane | |||||

| 20ºC | 100ºC | 200ºC | 300ºC | 400ºC | 600ºC |

| 1 | 1.006 | 1.012 | 1.018 | 1.025 | 1.018 |

| 700ºC | 800ºC | 900ºC | 1000ºC | 1100ºC | 1300ºC |

| 1.01 | 1.008 | 1.01 | 1.014 | 1.021 | - |

Uhlobo lokubonelela

| Igama lee-alloys | Uhlobo | Ubukhulu | ||

| I-Ni70Cr30W | Ucingo | D=0.03mm~8mm | ||

| I-Ni70Cr30R | Iribhoni | W=0.4~40 | T=0.03~2.9mm | |

| I-Ni70Cr30S | Umcu | W=8~250mm | T=0.1~3.0 | |

| I-Ni70Cr30F | Ifoyile | W=6~120mm | T=0.003~0.1 | |

| I-Ni70Cr30B | Ibhari | Ububanzi = 8 ~ 100mm | L=50~1000 | |

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu