Wamkelekile kwiwebhusayithi zethu!

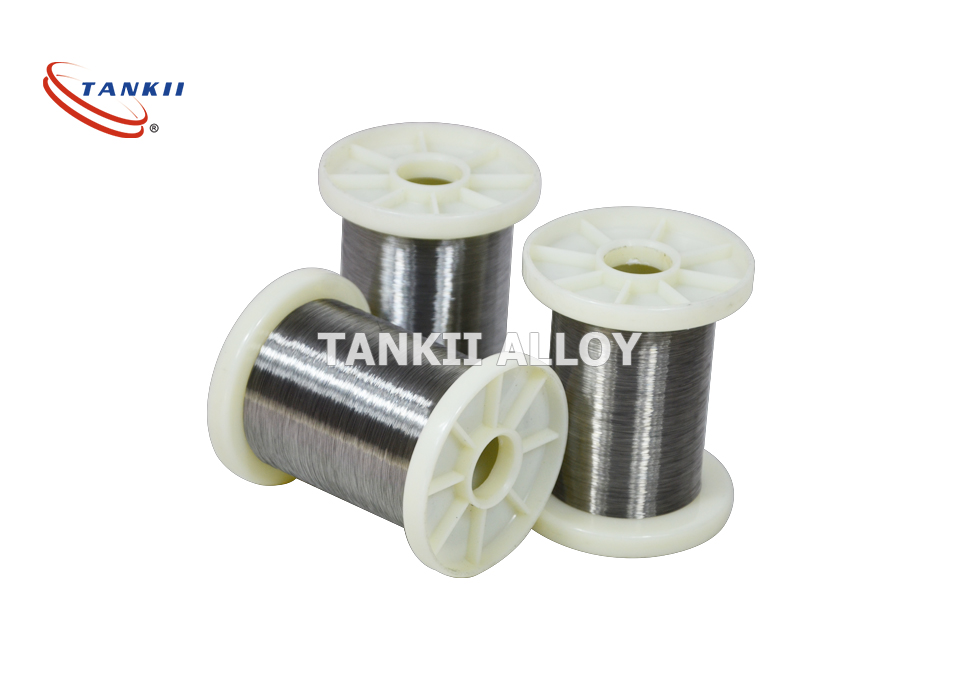

Intambo yokumelana ye-GY FeCrAl 0Cr25Al5 ye-tubular heater

Ucingo lokumelana ne-GY FeCrAl OCr25Al5isifudumezi setyhubhu

| Igama lemveliso | Uluhlu lobungakanani |

| Ucingo lokudweba olubandayo | Ububanzi 0.03-7.5mm |

| Intonga yocingo eqengqelekayo eshushu | Ububanzi 8.0-12mm |

| Iribhoni | Ubukhulu 0.05-0.35mm |

| Ububanzi 0.5.0-3.5mm | |

| Umcu osongiweyo obandayo | Ubukhulu 0.5-2.5mm |

| Ububanzi 5.0-40mm | |

| umcu osongiweyo oshushu | Ubukhulu 4-6mm |

| Ububanzi 15-40mm |

Malunga ne-Resistance Heating Wire:

Singumvelisi obalaseleyo wobuchwephesha we-resistance heating alloy eTshayina, sigxile kwi-Ferro-Chrome (Fe-Cr-AL) wire, i-Nickel-Chrome (Nichrome) wire, i-Copper Nickel (Constantan) wire, i-Stainless steel wire kunye neemveliso ezinxulumene nayo kwii-alloys ezenzelwe ukuhlangabezana neemfuno zabathengi ezithile.

Iinkcukacha zobungakanani

iiparameter ezisisiseko:

| iiparameter ezisisiseko | I-Kanthall APMTM | IKanthall | ||

| A-1 | AF | D | ||

| Ubushushu obuphezulu bokusebenza obuqhubekayo | 1425 | 1400 | 1300 | 1300 |

| Ulwakhiwo lweekhemikhali oluqhelekileyo,% Cr | 22 | 22 | 22 | 22 |

| AI | 5.8 | 5.8 | 5.3 | 4.8 |

| Fe | izithako | izithako | izithako | izithako |

| Ni | - | - | - | - |

| Ukumelana ne-resistivity kwi-20ºC,Ωmm-2mm-1 | 1.45 | 1.45 | 1.39 | 1.35 |

| uxinano, g/cm3 | 7.1 | 7.1 | 7.15 | 7.25 |

| I-coefficient yokwandiswa kobushushu i-K-1 20-750ºC | 14×10-6 | 14×10-6 | 14×10-6 | 14×10-6 |

| 20-1000ºC | 15×10-6 | 15×10-6 | 15×10-6 | 15×10-6 |

| Ukuqhuba kobushushu obuyi-20ºC,Wm-1K-1 | 13 | 13 | 13 | 13 |

| Umthamo othile wobushushu 20ºC, KJkg-1K-1 | 0.46 | 0.46 | 0.46 | 0.46 |

| Iqondo lokunyibilikaºC | 1500 | 1500 | 1500 | 1500 |

| Mhlawumbi iimpawu zoomatshini | ||||

| Amandla okuxinana, N mm-2 | 680 | 680 | 680 | 650 |

| Amandla okuvelisa, N mm-2 | 470 | 475 | 475 | 450 |

| Ubunzima, i-Hv | 230 | 230 | 230 | 230 |

| Ukuphuka kobude,% | 20 | 18 | 18 | 18 |

| Amandla e-900ºCT, N mm-2 | 40 | 34 | 37 | 34 |

| Amandla okuhamba 800ºC | 11 | 6 | 8 | 6 |

| 1000ºC | 3.4 | 1 | 1.5 | 1 |

| Imagnethi | imagnethi (Kwiqondo lobushushu eliyi-600ºC) | |||

| Ukukhupha umoya, iimeko ze-oxidation | 0.7 | 0.7 | 0.7 | 0.7 |

Inkcazo:

| Uhlobo lwe-alloy | Ububanzi | Ukuxhathisa | Ukutsalwa | Ukwandiswa(%) | Ukugoba | Ubuninzi.Okuqhubekayo | Ubomi bokuSebenza |

| (mm) | (μΩm)(20°C) | Amandla | Amaxesha | Inkonzo | (iiyure) | ||

| (N/mm²) | Ubushushu(°C) | ||||||

| I-Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| I-Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥0.50 | 1.15±0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| I-Cr20Ni35 | <0.50 | 1.04±0.05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥0.50 | 1.06±0.05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

Inzuzo:

I-alloy ye-nickelchromium enokumelana okuphezulu nokuzinzileyo, ukumelana nokugqwala, ukumelana nokuxinana komphezulu ilungile, ingcono xa iphantsi kobushushu obuphezulu kunye namandla enyikima, i-ductility elungileyo, ukusebenza kakuhle kunye nokudityaniswa.

I-alloy ye-nickelchromium enokumelana okuphezulu nokuzinzileyo, ukumelana nokugqwala, ukumelana nokuxinana komphezulu ilungile, ingcono xa iphantsi kobushushu obuphezulu kunye namandla enyikima, i-ductility elungileyo, ukusebenza kakuhle kunye nokudityaniswa.

Bhala umyalezo wakho apha uze uwuthumele kuthi

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu