FENi52/Nilo 52/Feni52/Ingxubevange 52/ASTM F30 ucingo Strip for Magnetic Reed Switshi

I-Nife52/Nilo 52/Feni52/Ingxubevange 52/ASTM F30 strip yokutshintsha ingcongolo kazibuthe

I-alloy 52 Iqulethe i-52% ye-nickel kunye ne-48% yentsimbi kwaye isetyenziswa kakhulu kumashishini onxibelelwano.Ikwafumana isicelo kwiintlobo ezahlukeneyo zezicelo ze-elektroniki, ngakumbi kwiimpawu zeglasi.

I-alloy 52 yenye yeglasi ukuya kwintsimbi yokutywina ialloys eyenzelwe ukusetyenziswa ngeentlobo ezahlukeneyo zeeglasi ezithambileyo. Eyaziwa ngokuba yi-coefficient yokwanda kwe-thermal ephantse iqhubeke ukuya kwi-1050F (565 C).

Uluhlu lobungakanani:

*Ishiti-Ubukhulu 0.1mm ~ 40.0mm, ububanzi: ≤300mm, imeko: kubanda kuqengqeleka (kushushu), kuqaqambile, kuqaqambe annealed

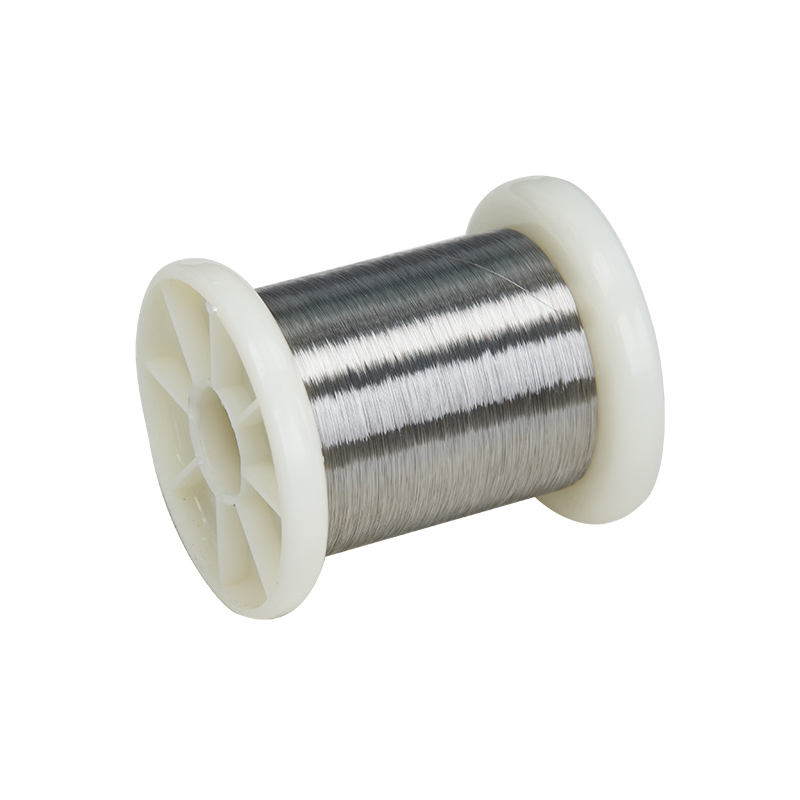

*Ucingo olusangqa-Dia 0.1mm~Dia 5.0mm,Imeko: izotyiwe ebandayo, eqaqambileyo, eqaqambileyo efakwe

*Intambo yocingo-I-Dia 0.5mm~Dia 5.0mm, ubude: ≤1000mm, imeko: i-flat rolling, i-annealed eqaqambileyo

*Ibha-Dia 5.0mm~Dia 8.0mm, ubude: ≤2000mm, imeko: iyabanda, iyaqaqamba, iqaqambile annealed

I-Dia 8.0mm ~ Dia 32.0mm, ubude: ≤2500mm, imeko: ishushu iqengqeleke, iqaqambile, iqaqambile

I-Dia 32.0mm~Dia 180.0mm, ubude:≤1300mm, imeko: ishushu, icwecwe, iguqulwe, iphathwe shushu

* I-Capillary-OD 8.0mm ~ 1.0mm, i-ID 0.1mm ~ 8.0mm, ubude: ≤2500mm, Umqathango: utsalwa ngokubanda, oqaqambileyo, okhanyayo.

*Umbhobho-OD 120mm ~ 8.0mm, i-ID 8.0mm ~ 129mm, ubude: ≤4000mm, Umqathango: utsalwa ngokubanda, ugqamile, ugqamile.

IKhemistri:

| Cr | Al | C | Fe | Mn | Si | P | S | Ni | Mg | |

| Min | - | - | - | - | - | - | - | - | 50.5 | - |

| Max | 0.25 | 0.10 | 0.05 | UBhal. | 0.60 | 0.30 | 0.025 | 0.025 | - | 0.5 |

I-Avareji yoLwandiso loMda lomlinganiso:

| IBanga | α1/10-6ºC-1 | |||||||

| 20 ~ 100ºC | 20-200ºC | 20-300ºC | 20-350ºC | 20-400ºC | 20-450ºC | 20 ~ 500ºC | 20 ~ 600ºC | |

| 4J52 | 10.3 | 10.4 | 10.2 | 10.3 | 10.3 | 10.3 | 10.3 | 10.8 |

Iinkcazelo ngeempawu:

| Imeko | Malunga. tensile strength | Malunga. ubushushu bokusebenza | ||

| N/mm² | ksi | °C | °F | |

| I-Anealed | 450 - 550 | 65 – 80 | ukuya kuthi ga kuma +450 | ukuya kuthi ga +840 |

| Izotywe nzima | 700 - 900 | 102 – 131 | ukuya kuthi ga kuma +450 | ukuya kuthi ga +840 |

| Ukubumba: |

| I-alloy ine-ductility efanelekileyo kwaye inokuqulunqwa ngeendlela eziqhelekileyo. |

| Ukuwelda: |

| I-Welding ngeendlela eziqhelekileyo zifanelekile kule alloy. |

| Unyango loBubushushu: |

| I-alloy 52 kufuneka ifakwe kwi-1500F ilandelwa kukupholisa umoya. Ukunciphisa ubunzima obuphakathi kunokwenziwa kwi-1000F. |

| Ukuqulunqa: |

| Ukubunjwa kufuneka kwenziwe kwiqondo lobushushu le-2150 F. |

| Ukusebenza Okubandayo: |

| I-alloy iyasebenza ngokukhawuleza. Umgangatho womzobo onzulu kufuneka ucaciswe kulo msebenzi wokubumba kunye nebakala elidityanisiweyo lokwenziwa ngokubanzi. |

Iindidi zeemveliso

-

Ifowuni

-

I-imeyile

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Phezulu