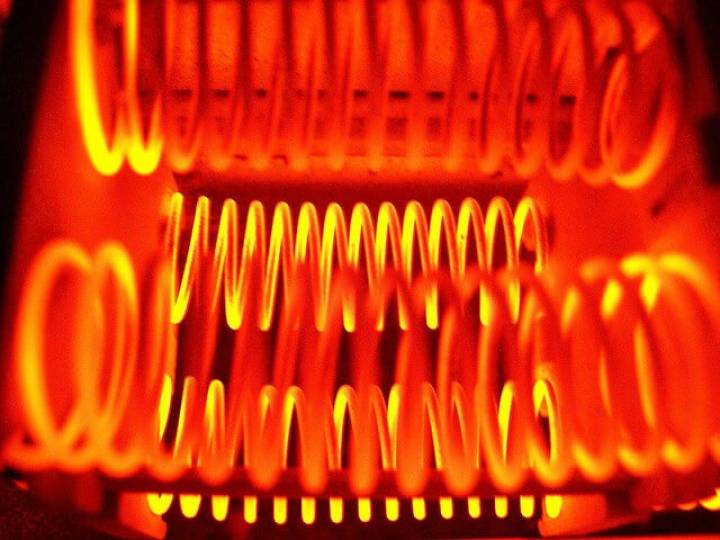

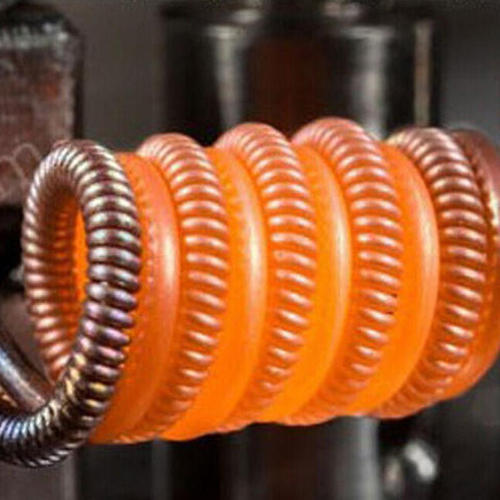

I-FeCrAl 0Cr25Al5 yokufudumeza isitovu sombane i-coil yokufudumeza ucingo

Ipropati ephambili yocingo lokumelana nokufudumeza

| Uhlobo lwe-alloy | Ububanzi (mm) | Ukuxhathisa (μΩm)(20°C) | Ukutsalwa Amandla (N/mm²) | Ukwandiswa(%) | Ukugoba Amaxesha | Ubuninzi.Okuqhubekayo Inkonzo Ubushushu(°C) | Ubomi bokuSebenza (iiyure) |

| I-Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| I-Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥0.50 | 1.15±0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| I-Cr20Ni35 | <0.50 | 1.04±0.05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥0.50 | 1.06±0.05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

| IGAMA | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| IKHEMIKALI ENGUMBO | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| ULWAKHIWO | Re | elifanelekileyo | elifanelekileyo | elifanelekileyo | elifanelekileyo | elifanelekileyo | elifanelekileyo | elifanelekileyo |

| Fe | Ukuphumla | Ukuphumla | Ukuphumla | Ukuphumla | Ukuphumla | Ukuphumla | Ukuphumla | |

| Inombolo 0.5 | Umhla 1.8-2.2 | |||||||

| UBUSHUSHU OBUPHEZULU(oC) | 650 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| UKUTHINTEKA20oC (μΩ·m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| UXINANO(g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| UTSHINTSHO LWEZOKUSHUSHU | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| IZINGA(KJ/m·h·oC) | ||||||||

| izinga lokwandiswa (α×10-6/oC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| indawo yokunyibilika (oC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| amandla okuxinana (N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| ubude (%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| ukwahluka kwendawo(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| ukugoba rhoqo (F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| ubulukhuni (HB) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| isakhiwo se-micrographic | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | |

| ipropati yemagnethi | Imagnethi | Imagnethi | Imagnethi | Imagnethi | Imagnethi | Imagnethi | Imagnethi | |

| Ububanzi(mm) | Ukunyamezelana (mm) | Ububanzi(mm) | Ukunyamezelana (mm) |

| 0.03-0.05 | ±0.005 | >0.50-1.00 | ± 0.02 |

| >0.05-0.10 | ±0.006 | >1.00-3.00 | ±0.03 |

| >0.10-0.20 | ±0.008 | >3.00-6.00 | ± 0.04 |

| >0.20-0.30 | ±0.010 | >6.00-8.00 | ±0.05 |

| >0.30-0.50 | ±0.015 | >8.00-12.0 | ± 0.4 |

| Ubukhulu (mm) | Ukunyamezelana (mm) | Ububanzi(mm) | Ukunyamezelana (mm) |

| 0.05-0.10 | ±0.010 | 5.00-10.0 | ± 0.2 |

| >0.10-0.20 | ±0.015 | >10.0-20.0 | ± 0.2 |

| >0.20-0.50 | ±0.020 | >20.0-30.0 | ± 0.2 |

| >0.50-1.00 | ±0.030 | >30.0-50.0 | ± 0.3 |

| >1.00-1.80 | ±0.040 | >50.0-90.0 | ± 0.3 |

| >1.80-2.50 | ±0.050 | >90.0-120.0 | ± 0.5 |

| >2.50-3.50 | ±0.060 | >120.0-250.0 | ± 0.6 |

Singumvelisi wentambo yokumelana nobushushu ibandakanya

ucingo lwe-FeCrAL, ucingo lwe-NiCr, ucingo lwaseCuNi:

II Inzuzo ephambili kunye nesicelo

A. Ipharamitha ebonakalayo:

1) Ububanzi bentambo: 0.025 ~ 15mm

2) I-nickel ecocekileyo inamandla okumelana namaqondo obushushu aphezulu ngaphandle kokuwohloka. Ukusebenza okuphezulu

ubushushu bumalunga nama-600°C

3) Ucingo lweNickel luyafumaneka ngokwakhiwa komtya omnye okanye imitya emininzi. Lufumaneka kwisitokhwe nokuba lungenanto, okanye lugqunywe nge-insulation

B. Iimpawu:

1) Ukuthe tye okugqwesileyo

2) Imeko efanayo nentle yomphezulu engenamabala

3) Ubuchule obuhle kakhulu bokwenza ikhoyili

C. Izicelo eziphambili kunye nenjongo ngokubanzi:

1) Le ntambo ingasetyenziswa kakhulu kwiikhaphu ze-transistor, ii-anode zeetyhubhu ze-elektroniki,

iileyidi zezixhobo ze-elektroniki / iingcingo zeleyidi zezibane kunye neengcingo ze-wire-mesh. Zikwasetyenziswa kwimo yestrip kwiindidi ezahlukeneyo

usetyenziso oluquka iibhetri zeNi-Cd

2) Ikwasetyenziswa kwiintambo, I-Lead-in-Wire yezibane, izixhasi zeetyhubhu ze-elektroniki, ilaphu lentambo, iilead zokudibanisa umbane

apho amaqondo obushushu egqitha lawo afanelekileyo ubhedu, ukuluka ucingo

3) Ukusetyenziswa okuqhelekileyo kuquka: iziphelo zezinto zokufudumeza njengakwii-oven, iiplastiki, ii-extruders, ii-oven.

Iinkxaso zefilament kunye neentambo zelothe kushishino lokukhanyisa

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu