Wamkelekile kwiwebhusayithi zethu!

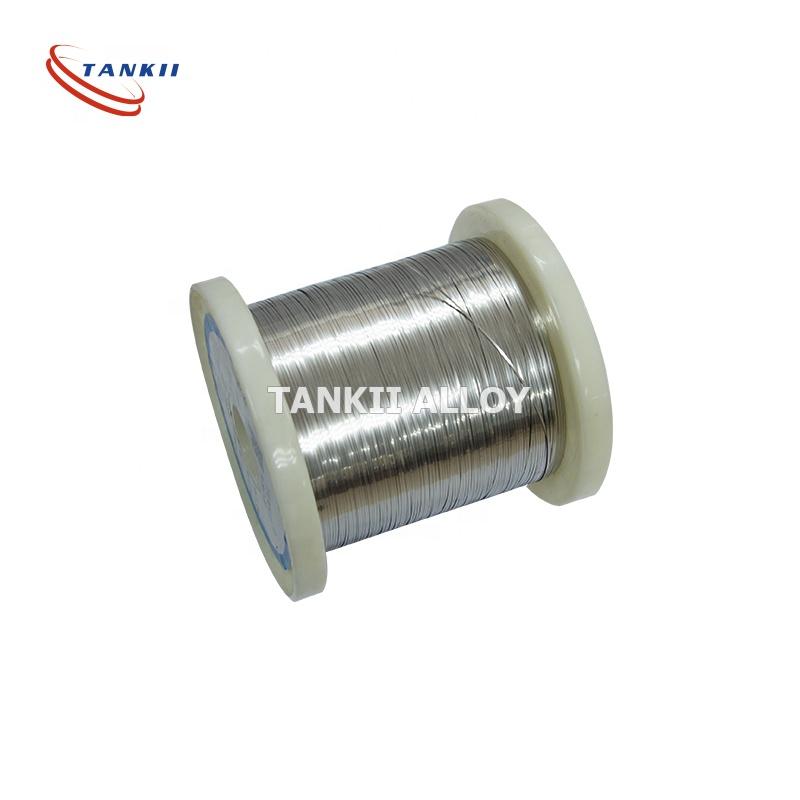

I-FeCrAl 0cr23al5 into yokufudumeza ucingo olusicaba kunye nomcu owenziwe ngumzi-mveliso

I-FeCrAl 0cr23al5 isixhobo sokufudumeza ucingo olusicaba kunyeumcungumzi-mveliso

| Ibanga | 0Cr23Al5 |

| Ubungakanani | ubukhulu: 0.05-3mm ububanzi: 4-250mm |

| Umphezulu | ukunqumla okukhanyayo |

| Ubunzima | 1-3kg/roll, ngokobungakanani babathengi |

| Ukuxhathisa | 1.3±0.05μΩ.m |

| Ubulukhuni (HV) | 180-210HV |

| Ukwandiswa | ≥16% |

| Ibanga | Ubushushu obuphezulu | Ukuxhathisa | Ukuqina | Tensile strength | Ukwandiswa |

| 0Cr13Al4 | 1050℃ | 1.25±0.05μΩ.m | 180-210HV | ≥550N/mm2 | ≥16 |

| 0Cr15Al5 | 1100℃ | 1.3±0.05μΩ.m | 180-210HV | ≥550N/mm2 | ≥16 |

| 0Cr21Al6Nb | 1300℃ | 1.42±0.05μΩ.m | 200-240HV | 750N/mm2 | ≥12 |

| I-Cr20Ni80 | 1200℃ | 1.09±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Cr15Ni60 | 1150℃ | 1.12±0.05μΩ.m | 175-210HV | 750N/mm2 | ≥20 |

| I-Cr20Ni35 | 1100℃ | 1.04±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| I-Cr25Ni20(310S) | 1100℃ | 0.86±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Ibanga | Ukwakheka kweekhemikhali% | ||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | |

| ≤ | |||||||||

| 0Cr15Al5 | 0.04 | 0.02 | 0.01 | 0.3 | ≤0.5 | 13-14 | 1 | 4.8-5.0 | ibhalansi |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.02 | 0.5 | ≤0.6 | 21-23 | ≤0.6 | 5-7 | ibhalansi |

| 0Cr13Al4 | 0.04 | 0.02 | 0.01 | 0.3 | ≤0.5 | 13-14 | 1 | 4.8-5.0 | ibhalansi |

| I-Cr20Ni80 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.6 | 20-23 | ibhalansi | 0.5 | ≤1.0 |

| Cr15Ni60 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.6 | 15-18 | 55-61 | 0.5 | ibhalansi |

| I-Cr20Ni35 | 0.08 | 0.02 | 0.015 | 1.0 | 1-3 | 18-21 | 34-37 | - | ibhalansi |

| I-Cr25Ni20 | 0.08 | 0.045 | 0.03 | 2.0 | 0.4-0.6 | 24-26 | 19-22 | - | ibhalansi |

IShanghai Tankii ALLOY Material Co., Ltd. igxile kwimveliso ye-nichrome alloy, i-thermocouple wire, i-fecral alloy, i-precision alloy, i-copper nickel alloy, i-thermal spray alloy njl.njl. ngohlobo lwe-wire, iphepha, iteyiphu,umcu,intonga nepleyiti.

Sele sinesatifikethi senkqubo yomgangatho we-ISO 9001 kunye nokuvunywa kwenkqubo yokukhusela okusingqongileyo ye-ISO 14001. Sineseti epheleleyo yemveliso ephucukileyo yokucocwa, ukunciphisa ukubanda, ukuzoba kunye nokunyanga ubushushu njl. Sikwanomthamo we-R&D ozimeleyo.

Bhala umyalezo wakho apha uze uwuthumele kuthi

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu