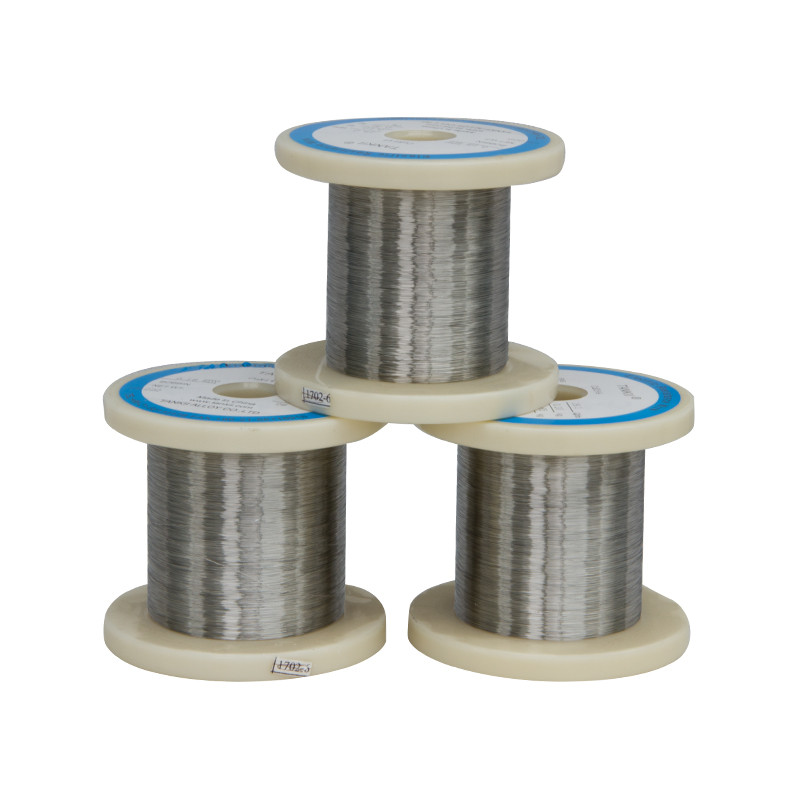

Ixabiso leFektri I-Permalloy 1j85/1j79 1j50 Ni50 1j46 Ni46 Uns 45-Permalloy Soft Magnetic Alloy Wire

Isetyenziswa kakhulu kwiindawo ezimbini zokuguqula amandla kunye nokucubungula ulwazi

Kwishishini lamandla, ikakhulu kwi-magnetic field ephezulu kukho i-induction ephezulu ye-magnetic kunye nokulahleka okuphantsi kwe-alloy. Kwishishini le-elektroniki, ikakhulu kwi-alloy ephantsi okanye ephakathi ene-magnetic permeability ephezulu kunye namandla aphantsi okunyanzela. Kwi-frequency ephezulu kufuneka kwenziwe kwi-strip encinci okanye i-alloy resistivity ephezulu. Ngokwesiqhelo ngephepha okanye i-strip.

Izinto zemagnethi ezithambileyo ezitshintshiselana nokusetyenziswa, ngenxa yemisinga yemagnethi etshintshanayo ebangelwa ngaphakathi kwezinto, nto leyo ebangela ukulahleka, kokukhona ukumelana kwe-alloy kuncinci, kokukhona ubukhulu bukhula, kokukhona intsimi yemagnethi etshintshanayo iphakama, ukulahleka komsinga we-eddy kukhulu, ukuncipha kombane wemagnethi. Ngenxa yoku, izinto kufuneka zenziwe iphepha elincinci (iteyipu), kwaye umphezulu ugqunywe ngomaleko wokuthintela, okanye ukusetyenziswa kweendlela ezithile kumphezulu ukwenza umaleko wokuthintela i-oxide, ezi ntlobo ze-alloys zihlala zisetyenziswa njenge-magnesium oxide electrophoresis coating.

I-iron-nickel alloy ikakhulu isetyenziswa kwi-alternating magnetic field, ikakhulu kwi-yoga iron, i-relay, ii-Small Power Transformers kunye ne-Magnetically shielded.

Nazi iinkcukacha zeemveliso zethu ze-1J80:

Ukwakheka kweekhemikhali

| ukwakheka | C | P | S | Mn | Si |

| ≤ | |||||

| Umxholo(%) | 0.03 | 0.020 | 0.020 | 0.60~1.10 | 1.10~1.50 |

| ukwakheka | Ni | Cr | Mo | Cu | Fe |

| Umxholo(%) | 79.0~81.5 | 2.60~3.00 | - | ≤0.2 | I-Bal |

Inkqubo yonyango lobushushu

| uphawu lwevenkile | Isixokelelwano sokutsala | ubushushu bokufudumeza | Gcina ixesha lobushushu/h | Izinga lokuphola |

| 1j80 | I-hydrogen eyomileyo okanye i-vacuum, uxinzelelo alukho ngaphezu kwe-0.1 Pa | Kunye nesithando somlilo sifudumeza i-1100~1150ºC | 3~6 | Kwi-100 ~ 200 ºC / h isantya sokupholisa ukuya kwi-400 ~ 500 ºC, ngokukhawuleza ukuya kwi-200 ºC tsala itshaja |

1J06,1J12,1J17,1J18,1J22,1J30,1J36,1J38,1J46,1J50,1J51,1J54,1J76,1J77,1J79,1J80,1J85,1J87

I-alloy yemagnethi esisigxinaAyinabo nje kuphela ubulukhuni obuphezulu kunye neempawu zoomatshini, kodwa ikwanabo nobuchule obuqinileyo bokulwa nokususwa kwemagnethi, ixabiso eliphezulu lokunyanzela (elingaphezulu kwe-20kA/m2), "inzima" yemagnethi kunye nezinye iimpawu, ngoko ke ikwabizwa ngokuba yi-hard magnetic alloy.2J04,2J07,2J09,2J10,2J31,2J53,2J84,2J85 Ii-alloys ze-elasticIquka ii-alloys eziphezulu ze-elastic kunye nee-alloys ezihlala zihleli ze-elastic. Isetyenziselwa ukwenza izinto ze-elastic ezifana nezinto ezibuthathaka ze-elastic, izinto zokugcina amandla kunye nezinto ze-frequency kwizixhobo ezichanekileyo.3J01,3J21,3J53

Ii-alloys ze-elasticIquka ii-alloys eziphezulu ze-elastic kunye nee-alloys ezihlala zihleli ze-elastic. Isetyenziselwa ukwenza izinto ze-elastic ezifana nezinto ezibuthathaka ze-elastic, izinto zokugcina amandla kunye nezinto ze-frequency kwizixhobo ezichanekileyo.3J01,3J21,3J53

Iialloy zokwandisa (Invar Alloy)zahlulwe ngee-alloys zeKovar, ii-alloys ze-ceramic sealing, ii-alloys ze-low expansion, kunye nee-alloys ze-constant expansion. Zisetyenziswa kakhulu kushishino lwe-elektroniki, izixhobo zokulinganisa ngokuchanekileyo, izixhobo ze-precision kunye nobunjineli bobushushu obuphantsi kunye nezinye iindawo..

4J28,4J29,4J32,4J33,4J36,4J40,4J42,4J50

Ii-alloys ezichanekileyo ezine-nickel, i-chromium, i-aluminium kunye nesinyithi njengezona zinto ziphambili, ukumelana kwayo kuphindwe kathathu kunobhedu lwe-manganese, kwaye inomlinganiselo ophantsi wokumelana nobushushu kunye nokukwazi ubushushu obuphantsi kwi-copper, kunye nokuzinza okuhle kokumelana nexesha elide kunye nokumelana. Iipropati ze-oxidation.

Ifanelekile ukwenza izinto ezichanekileyo kwizixhobo ezahlukeneyo zokulinganisa kunye neemitha, ukwenza izinto ezichanekileyo zokuchaneka kunye neegeyiji zoxinzelelo.

6J10,6J15,6J20,6J22,6J23,6J24

| i-alloy yokwandisa | ||||||||||

| Ibanga | C≤ | S≤ | P≤ | Mn | Si | Ni | Cr | Cu | Al | Fe |

| 6J10 | ≤0.05 | ≤0.01 | ≤0.01 | ≤0.3 | ≤0.2 | i-nI+cO rem | 9-10 | ≤0.2 | ≤0.4 | |

| 6J15 | ≤0.05 | ≤0.02 | ≤0.03 | ≤1.5 | 0.4-1.3 | 55-61 | 15-18 | ≤0.3 | umva | |

| 6J20 | ≤0.05 | ≤0.01 | ≤0.01 | ≤0.7 | 0.4-1.3 | umva | 20-23 | ≤0.3 | ≥1.5 | |

| 6J22 | ≤0.04 | ≤0.01 | ≤0.01 | 0.5-1.5 | ≤0.2 | umva | 19-21.5 | 2.7-3.2 | 2-3 | |

| 6J23 | ≤0.04 | ≤0.01 | ≤0.01 | 0.5-1.5 | ≤0.2 | umva | 19-21.5 | 2-3 | 2.7-3.2 | |

| 6J24 | ≤0.04 | ≤0.01 | ≤0.01 | 1.0-3.0 | 0.9-1.5 | umva | 19-21.5 | 2.7-3.2 | ≤0.5 | |

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu