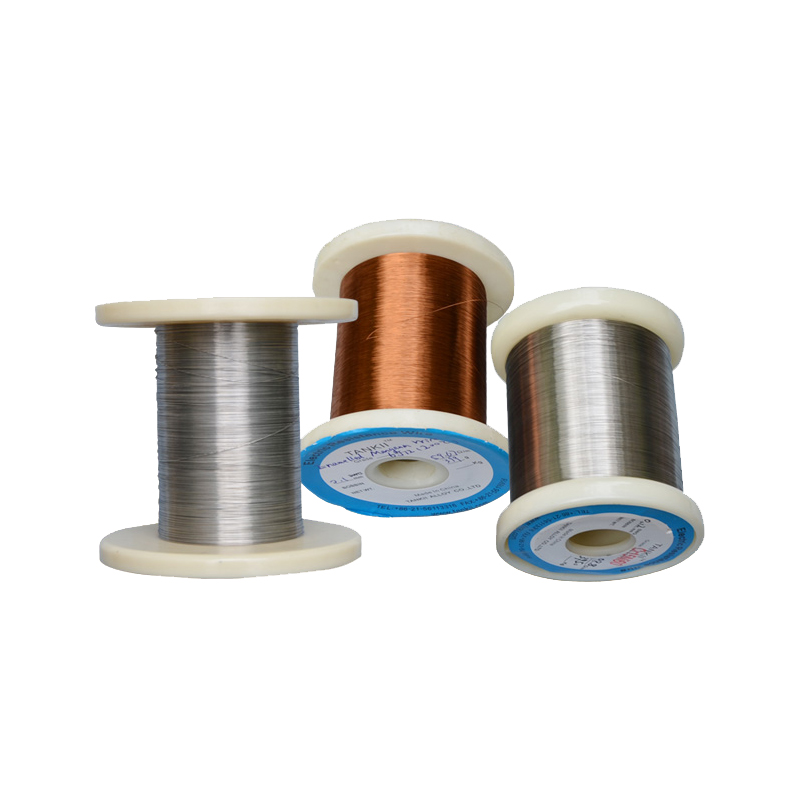

Ukumelana ne-Eureka Round/Flat Wire enamel

Ingcaciso yeMveliso

Ezi ntambo zokumelana ezine-enamel zisetyenziswa ngokubanzi kwii-resistor ezisemgangathweni, iimoto

iinxalenye, ii-resistors ezijikelezayo, njl. kusetyenziswa i-insulation processing efanelekileyo kwezi zicelo, kusetyenziswa ngokupheleleyo iimpawu ezikhethekileyo ze-enamel coating.

Ngaphezu koko, siza kusebenzisa i-enamel coating insulation kwiingcingo zesinyithi ezixabisekileyo ezifana nesilivere kunye neplatinum xa ziodolwe. Nceda usebenzise le mveliso-ngoku-odolwa.

Uhlobo lokuvala:

1) Ucingo lokumelana nepolyester, udidi lwe-130

2) Ucingo oluhlengahlengisiweyo lokumelana ne-polyester, udidi lwe-155

3) Ucingo lokumelana nePolyesterimide, udidi lwe-180

4) I-Polyester (imide) egqunywe ngocingo lokumelana ne-polyamide-imide, iklasi 200

5) Ucingo lokumelana nePolyimide, udidi 220

Intambo yeBare Wire

| uhlobo lwepropati ephambili | I-Cuni1 | I-CuNI2 | I-CuNI6 | I-CuNi8 | I-CuNI10 | I-CuNi14 | I-CuNi19 | I-CuNi23 | I-CuNi30 | I-CuNi34 | I-CuNI44 | |

| ulwakhiwo oluphambili lweekhemikhali | Ni | 1 | 2 | 6 | 8 | 10 | 14.2 | 19 | 23 | 30 | 34 | 44 |

| MN | / | / | / | / | / | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| CU | ukuphumla | ukuphumla | ukuphumla | ukuphumla | ukuphumla | ukuphumla | ukuphumla | ukuphumla | ukuphumla | ukuphumla | ukuphumla | |

| ubushushu obuphezulu bokusebenza | / | 200 | 220 | 250 | 250 | 300 | 300 | 300 | 350 | 350 | 400 | |

| uxinano g/cm3 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| ukumelana nokuxhathisa kwi-20 °c | 0.03 ± 10% | 0.05±10% | 0.10±10% | 0.12±10% | 0.15±10% | 0.20±5% | 0.25±5% | 0.30±5% | 0.35±5% | 0.40±5% | 0.49±5% | |

| ukumelana nobushushu obufanelekileyo | <100 | <120 | <60 | <57 | <50 | <38 | <25 | <16 | <10 | -0 | <-6 | |

| i-mpa enamandla okutyhafa | >210 | >220 | >250 | >270 | >290 | >310 | >340 | >350 | >400 | >400 | >420 | |

| ubude | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | |

| indawo yokunyibilika °c | 1085 | 1090 | 1095 | 1097 | 1100 | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| i-coefficient ofconductivity | 145 | 130 | 92 | 75 | 59 | 48 | 38 | 33 | 27 | 25 | 23 |

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu