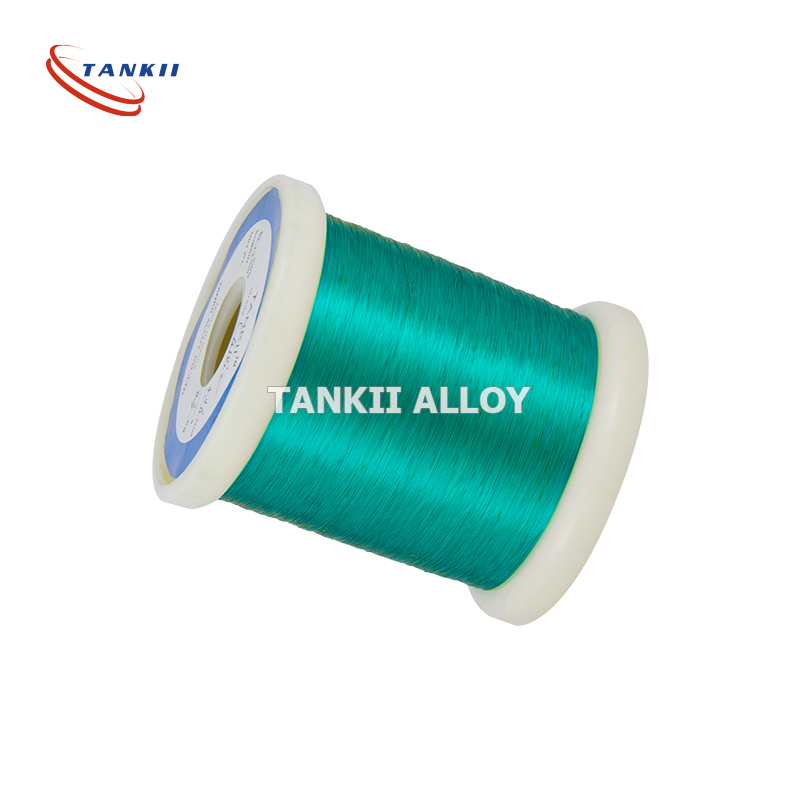

I-Enameled Nichrome /Constantan /Copper / Lizt / Intambo yombala / Isilivere / Intambo yeTwist

Ingcaciso yeMveliso

Ezi ntambo zokumelana ezine-enamel zisetyenziswa ngokubanzi kwii-resistor ezisemgangathweni, iimoto

iinxalenye, ii-resistors ezijikelezayo, njl. kusetyenziswa i-insulation processing efanelekileyo kwezi zicelo, kusetyenziswa ngokupheleleyo iimpawu ezikhethekileyo ze-enamel coating.

Ngaphezu koko, siza kusebenzisa i-enamel coating insulation kwiingcingo zesinyithi ezixabisekileyo ezifana nesilivere kunye neplatinum xa ziodolwe. Nceda usebenzise le mveliso-ngoku-odolwa.

Uhlobo lweNtambo yeNichrome

I-NiCr80/20, i-NiCr70/30, i-NiCr60/15, i-NiCr90/10, i-NiCr35/20, i-NiCr30/20

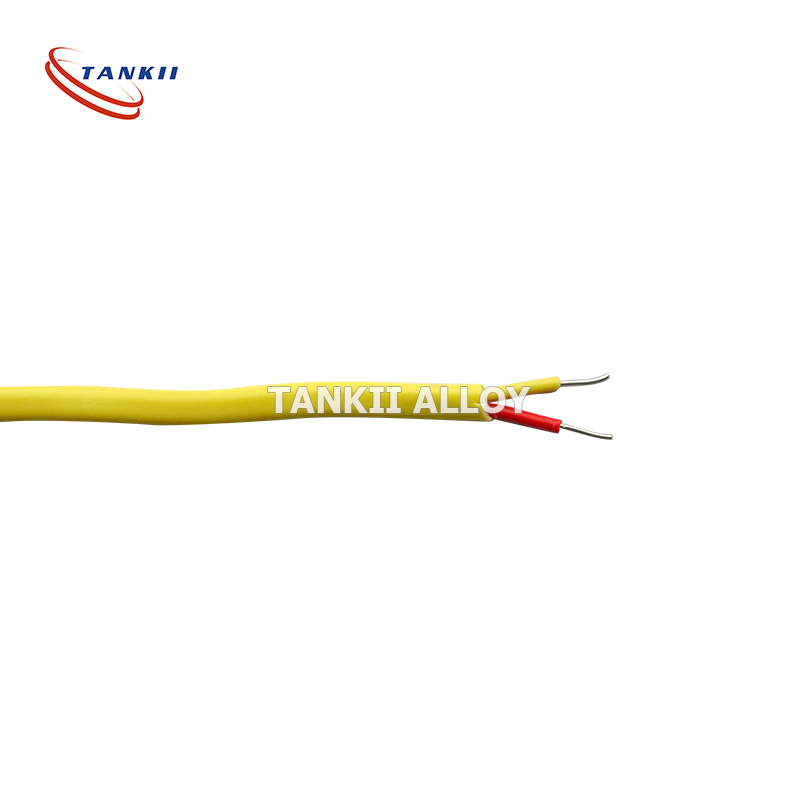

Uhlobo lokufaka ubushushu

| Igama elifakwe i-insulation enamel | Inqanaba lobushushuºC (Ixesha lokusebenza liyi-2000h) | Igama leKhowudi | Ikhowudi ye-GB | Uhlobo lwe-ANSI |

| Ucingo olune-enamel ye-polyurethane | 130 | I-UEW | QA | MW75C |

| Ucingo olufakwe i-polyester enamel | 155 | I-PEW | QZ | MW5C |

| Ucingo olune-enamel ye-polyester-imide | 180 | I-EIW | QZY | MW30C |

| I-polyester-imide kunye ne-polyamide-imide egqunywe kabiniucingo olune-enamel | 200 | I-EIWH (i-DFWF) | QZY/XY | MW35C |

| Ucingo olune-enamel lwe-polyamide-imide | 220 | I-AIW | QXY | MW81C |

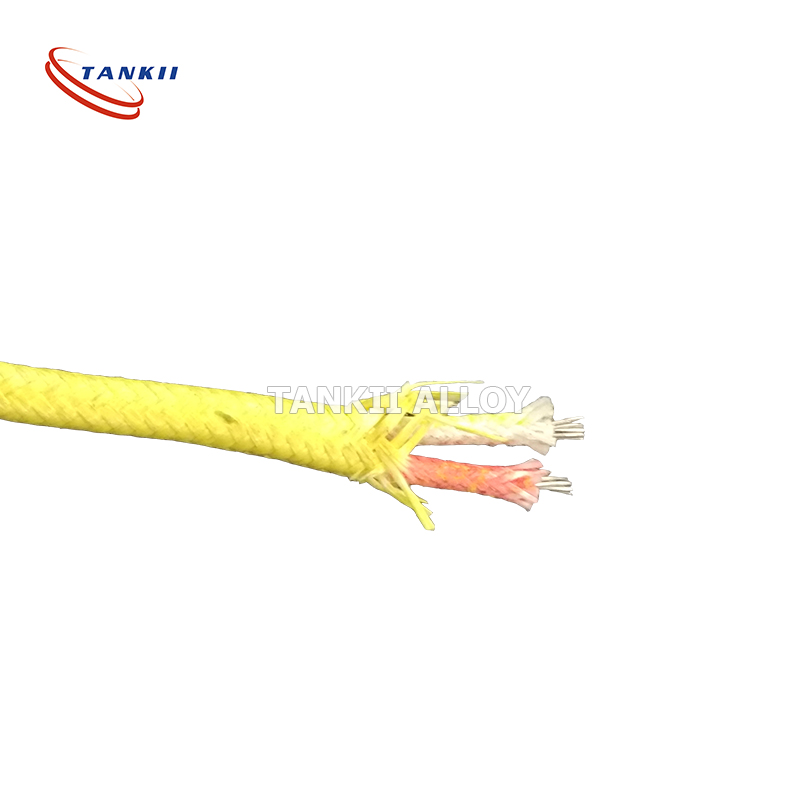

Uhlobo lweNtambo ye-Alloy engenanto

Iingxubevange esizenzayo ziyi-enamelled wire ye-Copper-nickel alloy, i-Constantan wire, i-Manganin wire. I-Kama Wire, i-NiCr Alloy wire, i-FeCrAl Alloy wire njl.

| eyona nto iphambili ipropati uhlobo | I-Cuni1 | I-CuNI2 | I-CuNI6 | I-CuNi8 | I-CuNI10 | I-CuNi19 | I-CuNi23 | I-CuNi30 | I-CuNi34 | I-CuNI44 | |

| eyona nto iphambili ikhemikhali ukwakheka | Ni | 1 | 2 | 6 | 8 | 10 | 19 | 23 | 30 | 34 | 44 |

| MN | / | / | / | / | / | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| CU | ukuphumla | ukuphumla | ukuphumla | ukuphumla | ukuphumla | ukuphumla | ukuphumla | ukuphumla | ukuphumla | ukuphumla | |

| ubuninzi ukusebenza ubushushu | / | 200 | 220 | 250 | 250 | 300 | 300 | 350 | 350 | 400 | |

| uxinano g/cm3 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| ukumelana nokuxhathisa kwi-20 °c | 0.03 ± 10% | 0.05± 10% | 0.10± 10% | 0.12± 10% | 0.15± 10% | 0.25± 5% | 0.30± 5% | 0.35± 5% | 0.40± 5% | 0.49± 5% | |

| ubushushu i-coefficient ye ukuxhathisa | <100 | <120 | <60 | <57 | <50 | <25 | <16 | <10 | -0 | <-6 | |

| ukuthamba amandla e-mpa | >210 | >220 | >250 | >270 | >290 | >340 | >350 | >400 | >400 | >420 | |

| ubude | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | |

| ukunyibilika inqaku °c | 1085 | 1090 | 1095 | 1097 | 1100 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| i-coefficient ye ukuhanjiswa komoya | 145 | 130 | 92 | 75 | 59 | 38 | 33 | 27 | 25 | 23 |

ucingo lokufudumeza lwe-nicr8020 alloy

1. Malunga nentambo yeNichrome

I-alloy ye-Nichrome iquka i-nickel ecocekileyo, i-alloy ye-NiCr, i-alloy ye-Fe-Cr-Al kunye ne-alloy ye-nickel yobhedu.

Ii-alloy ze-chrome ze-nickel: i-Ni80Cr20, i-Ni70Cr30, i-Ni60Cr15, i-Ni35Cr20, i-Ni30Cr20, i-Cr25Ni20, i-nickel ecocekileyo i-Ni200 kunye ne-Ni201

2.Inzuzo ephambili kunye nesicelo

1. I-alloy ye-nickel-chromium, i-nickel-chromium enokumelana okuphezulu nokuzinzileyo, ukumelana nokugqwala, ukumelana nokuxinana komphezulu kulungile, ingcono xa iphantsi kobushushu obuphezulu kunye namandla enyikima, i-ductility elungileyo, ukusebenza kakuhle kunye nokudityaniswa.

Iimveliso zethu zisebenza kakhulu kushishino lweekhemikhali, indlela yokwenza isinyithi, ishishini leglasi, ishishini le-ceramic, indawo yezixhobo zasekhaya njalo njalo.

1) Ulwakhiwo lweekhemikhali:

| Uphawu | Ukwakheka kweekhemikhali | Si | Cr | Ni | Al | Fe | |||

| C | P | S | Mn | ||||||

| Akukho ngaphezu | |||||||||

| I-Cr20Ni80 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 20.0-23.0 | hlala | ≤0.50 | ≤1.0 |

| Cr15Ni60 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 15.0-18.0 | 55.0-61.0 | ≤0.50 | hlala |

| I-Cr20Ni35 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-3.00 | 18.0-21.0 | 34.0-37.0 | - | hlala |

| I-Cr20Ni30 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-2.00 | 18.0-21.0 | 30.0-34.0 | - | hlala |

2) Ubungakanani kunye nokunyamezela

Xa imveliso ikwimeko ethi “M”, kufuneka ilandelwe yi-GB/T1234-1995 esemgangathweni.

1) Ukumelana noxinzelelo:

| Uphawu | I-Cr20Ni80 | I-Cr20Ni60 | I-Cr20Ni35 | I-Cr20Ni30 | ||

| Ububanzi mm | <0.50 | 0.50-3.0 | <0.50 | ≥0.50 | <0.50 | ≥0.50 |

| ukumelana (20°C)uΩ·m | 1.09±0.05 | 1.13±0.05 | 1.12±0.05 | 1.15±0.05 | 1.04±0.05 | 1.06±0.05 |

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu