I-Oven Wire yoMbane I-Electric Stove Wire I-Industrial Electric Furnace I-Heat Coil Engaxhathisiyo

I-Oven Wire yoMbane I-Electric Stove Wire I-Industrial Electric Furnace I-Electric Furnace I-Emergency Heat Wire

Iinkcukacha zajikelele

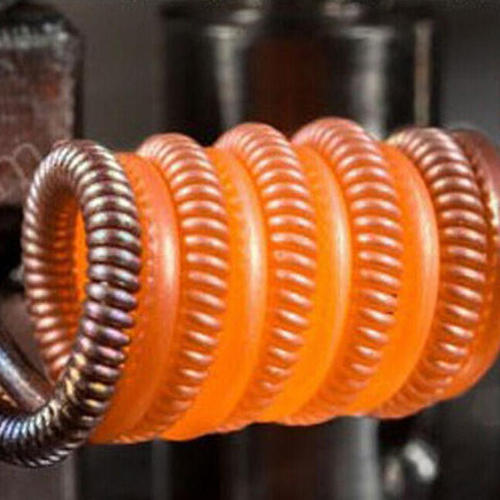

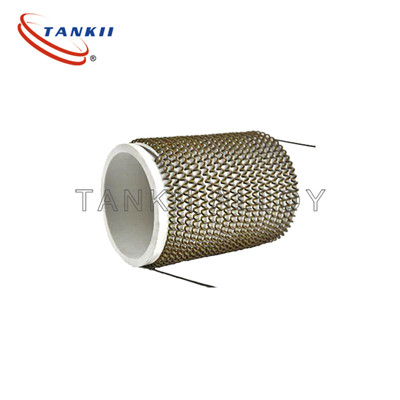

Intambo ye-oven yombane luhlobo lwentambo yombane ekwaziyo ukumelana nombane kakhulu. Le ntambo iyamelana nokuhamba kombane, kwaye iguqula amandla ombane abe bubushushu.

Ukusetyenziswa kwentambo yokumelana kuquka izithinteli, izinto zokufudumeza, izifudumezi zombane, ii-oveni zombane, ii-toaster, nezinye ezininzi.

I-Nichrome, i-alloy engeyiyo imagnethi ye-nickel kunye ne-chromium, isetyenziswa kakhulu ekwenzeni i-resistance wire kuba inokumelana okuphezulu kunye nokumelana ne-oxidation kumaqondo obushushu aphezulu. Xa isetyenziswa njengesixhobo sokufudumeza, i-resistance wire idla ngokubotshelelwa kwiikhoyili. Ubunzima obunye ekusebenziseni i-Electric Oven Wire kukuba i-common electrical solder ayinamatheli kuyo, ngoko ke uqhagamshelo kumandla ombane kufuneka lwenziwe kusetyenziswa ezinye iindlela ezifana nezihlanganisi ze-crimp okanye ii-screw terminals.

I-FeCrAl, usapho lwee-alloys ze-iron-chromium-aluminium ezisetyenziswa kwiintlobo ngeentlobo zokumelana nobushushu obuphezulu, ikwasetyenziswa ngendlela yeengcingo zokumelana.

Iimpawu kunye neempawu

| Uyilo lwezinto | Elinye Igama | Ulwakhiwo lweekhemikhali olubi | |||||

| Ni | Cr | Fe | Nb | Al | Ukuphumla | ||

| I-Nickel Chrome | |||||||

| I-Cr20Ni80 | I-NiCr8020 | 80.0 | 20.0 | ||||

| Cr15Ni60 | I-NiCr6015 | 60.0 | 15.0 | 20.0 | |||

| I-Cr20Ni35 | I-NiCr3520 | 35.0 | 20.0 | 45.0 | |||

| I-Cr20Ni30 | I-NiCr3020 | 30.0 | 20.0 | 50.0 | |||

| I-aluminiyam ye-Chrome yentsimbi | |||||||

| OCr25Al5 | I-CrAl25-5 | 23.0 | 71.0 | 6.0 | |||

| OCr20Al5 | I-CrAl20-5 | 20.0 | 75.0 | 5.0 | |||

| OCr27Al7Mo2 | 27.0 | 65.0 | 0.5 | 7.0 | 0.5 | ||

| OCr21Al6Nb | 21.0 | 72.0 | 0.5 | 6.0 | 0.5 | ||

| Uyilo lwezinto | Ukumelana µOhms/cm | Uxinano G/cm3 | I-Coefficient yoLwandiso oluLungileyo | Ukuqhuba kwe-Thermal W/mK | |

| µm/m.°C | Ubushushu°C | ||||

| I-Nickel Chrome | |||||

| I-Cr20Ni80 | 108.0 | 8.4 | 17.5 | 20-1000 | 15.0 |

| Cr15Ni60 | 112.0 | 8.2 | 17.5 | 20-1000 | 13.3 |

| I-Cr20Ni35 | 105.0 | 8.0 | 18.0 | 20-1000 | 13.0 |

| I-aluminiyam ye-Chrome yentsimbi | |||||

| OCr25Al5 | 145.0 | 7.1 | 15.1 | 20-1000 | 16.0 |

| OCr20Al5 | 135.0 | 7.3 | 14.0 | 20-1000 | 16.5 |

Izicelo eziCetyisiweyo

| Uyilo lwezinto | Iipropati zeNkonzo | Izicelo |

| I-Nickel Chrome | ||

| I-Cr20Ni80 | Iqulethe izongezo ezihlala ixesha elide ezenza ukuba ifaneleke kakhulu kwiizicelo ezixhomekeke ekutshintsheni rhoqo kunye nokuguquguquka okukhulu kobushushu. Ingasetyenziswa kumaqondo obushushu asebenzayo ukuya kuthi ga kwi-1150 °C. | Izithinteli zolawulo, izitofu zobushushu obuphezulu, ii-ironing irons. |

| Cr15Ni60 | I-alloy ye-Ni/Cr ene-balance ikakhulu i-Iron, enobomi obude. Ifanelekile ukusetyenziswa ukuya kuthi ga kwi-1100 °C, kodwa i-coefficient ephezulu yokumelana nayo yenza ukuba ifaneleke ukusetyenziswa okuncinci kune-80/20. | Izifudumezi zombane, izithinteli ezinzima, izitofu zombane. |

| I-Cr20Ni35 | Ilungelelanise ikakhulu i-Iron. Ifanelekile ukusebenza rhoqo ukuya kuthi ga kwi-1050°C, kwii-oven ezinee-atmospheres ezinokubangela ukugqwala okomileyo kwizixhobo eziphezulu ze-nickel. | Izifudumezi zombane, ii-oven zombane (ezine-atmospheres). |

| I-aluminiyam ye-Chrome yentsimbi | ||

| OCr25Al5 | Ingasetyenziswa kwiimeko zokusebenza ukuya kuthi ga kwi-1350°C, nangona inokuba buthathaka. | Izinto zokufudumeza zee-oven ezishushu kakhulu kunye nezifudumezi ezikhazimlayo. |

| OCr20Al5 | I-alloy ye-ferromagnetic enokusetyenziswa kumaqondo obushushu afikelela kwi-1300°C. Ifanele isetyenziswe kwindawo eyomileyo ukuze kuthintelwe ukugqwala. Ingaqhekeka xa amaqondo obushushu aphezulu. | Izinto zokufudumeza zee-oven ezishushu kakhulu kunye nezifudumezi ezikhazimlayo. |

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu