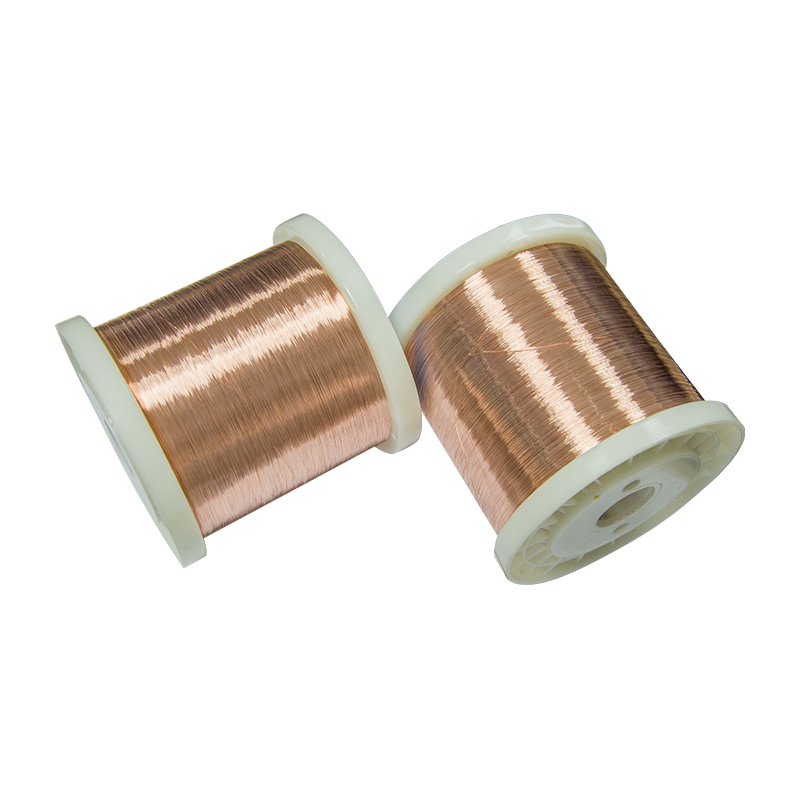

Iintambo zeBeryllium zeDia 0.6mm Alloy M25 Copper Beryllium zeeBridges zoQhagamshelwano

Ingcaciso yeMveliso

Ulwakhiwo lweeKhemikhali (Ipesenti yoBunzima)I-C17200 Beryllium Copper Alloy:

| Ukuhambisa izisombululo | ||||||

| I-alloy | IBeryllium | I-Cobalt | I-Nickel | Co + Ni | Co+Ni+Fe | Ithusi |

| C17200 | 1.80-2.00 | - | 0.20 Umzuzu | 0.20 Umzuzu | Ubuninzi be-0.60 | Ibhalansi |

Isaziso: Izongezo zeCopper kunye ne-99.5% Min.

TIimpawu eziqhelekileyo ze-C172:

Ubuninzi (g/cm3): 8.36

Uxinano ngaphambi kokuba luqine (g/cm3): 8.25

I-Elastic Modulus (kg/mm2 (103)): 13.40

I-Coefficient yokwandisa ubushushu (20 °C ukuya kwi-200 °C m/m/°C): 17 x 10-6

Ukuqhuba kwe-Thermal (cal/(cm-s-°C)): 0.25

Uluhlu lokunyibilika (°C): 870-980

Ubushushu obuqhelekileyo esibonelela ngabo:

| Utyumbo lweCuBeryllium | I-ASTM | Iimpawu zoomatshini nezombane zeCopper Beryllium Strip | ||||||

| Ukutyunjwa | Inkcazo | Tensile strength (I-Mpa) | Amandla okuVuna yi-0.2% isaphulelo | Ipesenti yobude | UBUQINI (HV) | UBUQINI uRockwell Isikali se-B okanye se-C | Ukuqhuba kombane (% IACS) | |

| A | TB00 | Isisombululo esiqhotyoshelweyo | 410~530 | 190~380 | 35~60 | <130 | 45~78HRB | 15~19 |

| 1/2 H | TD02 | Isiqingatha Esiqinileyo | 580~690 | 510~660 | 12~30 | 180~220 | 88~96HRB | 15~19 |

| H | TD04 | Kunzima | 680~830 | 620~800 | 2~18 | 220~240 | 96 ~ 102HRB | 15~19 |

| HM | TM04 | Iqinisiwe i-mill | 930~1040 | 750~940 | 9~20 | 270~325 | 28~35HRC | 17~28 |

| SHM | TM05 | 1030~1110 | 860~970 | 9~18 | 295~350 | 31~37HRC | 17~28 | |

| I-XHM | TM06 | 1060~1210 | 930~1180 | 4~15 | 300~360 | 32~38HRC | 17~28 | |

Ubuchwepheshe obuPhambili beBeryllium Copper (Unyango lobushushu)

Unyango lobushushu yeyona nkqubo ibalulekileyo kule nkqubo ye-alloy. Nangona zonke ii-alloy zobhedu ziqina xa zisebenza kubanda, i-beryllium copper yahlukile ekubeni iqina xa isetyenziswa ngobushushu obuphantsi. Ibandakanya amanyathelo amabini asisiseko. Elokuqala libizwa ngokuba yi-solution annealing kwaye elesibini, yi-precipitation okanye i-age hardening.

Isisombululo sokuNgcwaba

Kwi-alloy eqhelekileyo iCuBe1.9 (1.8- 2%), i-alloy ifudunyezwa phakathi kwe-720°C kunye ne-860°C. Kule ndawo i-beryllium equlethwe kuyo ngokuyintloko "iyanyibilika" kwi-matrix yobhedu (isigaba se-alpha). Ngokucima ngokukhawuleza ukuya kubushushu begumbi, ulwakhiwo lwesisombululo esiqinileyo luyagcinwa. Izinto ezikule nqanaba zithambile kakhulu kwaye zithambile kwaye zinokubanda ngokulula ngokutsala, ukwenza i-rolling, okanye i-cold heading. Umsebenzi wokufaka isisombululo uyinxalenye yenkqubo kwindawo yokusila kwaye awusetyenziswa rhoqo ngumthengi. Ubushushu, ixesha kubushushu, izinga lokucima, ubungakanani bengqolowa, kunye nobunzima zonke ziiparameter ezibalulekileyo kwaye zilawulwa ngokuqinileyo yi-TANKII.

Ukuqina kobudala

Ukuqina kokuguga kuyawomeleza kakhulu amandla ezinto. Olu hlobo lokusabela lwenziwa rhoqo kumaqondo obushushu aphakathi kwama-260°C nama-540°C kuxhomekeke kwi-alloy kunye neempawu ezifunwayo. Lo mjikelo ubangela ukuba i-beryllium enyibilikisiweyo ifikelele njengesigaba se-beryllium etyebileyo (gamma) kwi-matrix nakwimida yeenkozo. Kukwakheka kwale precipitate okubangela ukwanda okukhulu kwamandla ezinto. Inqanaba leempawu zoomatshini ezifunyenweyo limiselwa bubushushu kunye nexesha kubushushu. Kufuneka kuqatshelwe ukuba i-beryllium copper ayinazo iimpawu zokuguga kubushushu begumbi.

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu