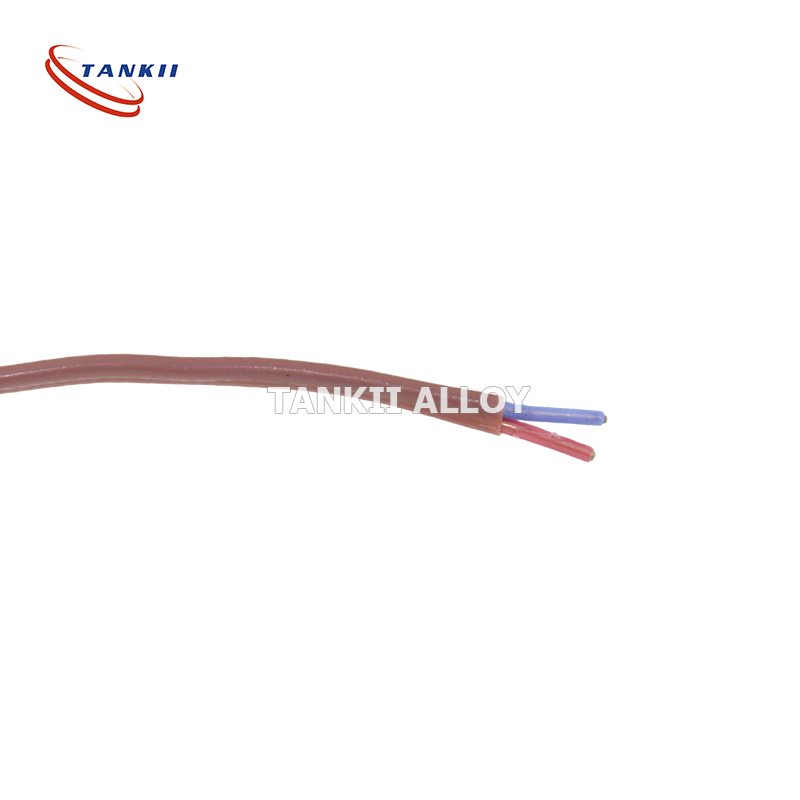

Ucingo lobhedu olujikelezileyo olune-enamel yeClass F/i-polyester eguquliweyo

Iklasi Fi-nylon/i-polyester eguquliweyo ene-enamel ejikelezileyoucingo lobhedu

Ingcaciso yeMveliso

Ezi ntambo zokumelana ezine-enamel zisetyenziswa ngokubanzi kwii-resistor ezisemgangathweni, iimoto

iindawo, izithinteli zokujikeleza, njl. kusetyenziswaubushushu bomzimbaukucubungula kulungele kakhulu ezi zicelo, kusetyenziswa ngokupheleleyo iimpawu ezikhethekileyo zokwambathisa i-enamel.

Ngaphezu koko, siza kucoca i-enamel.ubushushu bomzimbaucingo lwesinyithi oluxabisekileyo olufana nolwesilivere nolweplatinum xa luodolwa. Nceda usebenzise olu hlobo lokuvelisa xa luodolwa.

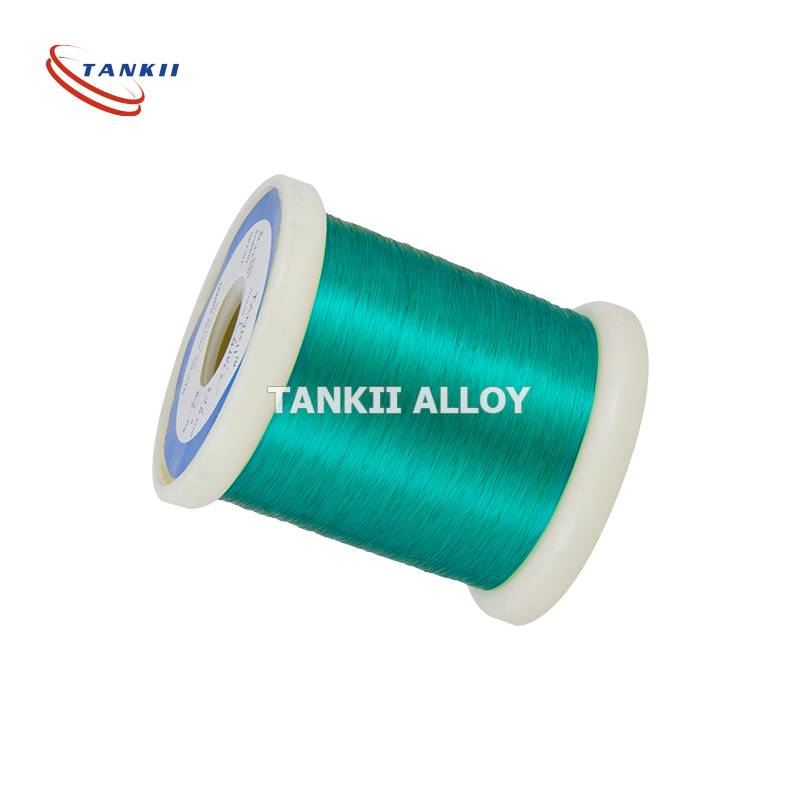

Uhlobo lwentambo ye-Alloy engenanto

Iingxubevange esizenzayo ziyi-enamelled wire ye-Copper-nickel alloy, i-Constantan wire, i-Manganin wire. I-Kama Wire, i-NiCr Alloy wire, i-FeCrAl Alloy wire njl.

Uhlobo lokukhusela ubushushu

| Igama elifakwe i-insulation enamel | Inqanaba lobushushuºC (Ixesha lokusebenza liyi-2000h) | Igama leKhowudi | Ikhowudi ye-GB | Uhlobo lwe-ANSI |

| Ucingo olune-enamel ye-polyurethane | 130 | I-UEW | QA | MW75C |

| Ucingo olufakwe i-polyester enamel | 155 | I-PEW | QZ | MW5C |

| Ucingo olune-enamel ye-polyester-imide | 180 | I-EIW | QZY | MW30C |

| Ucingo olune-enamel olufakwe i-polyester-imide kunye ne-polyamide-imide olufakwe kabini | 200 | I-EIWH (i-DFWF) | QZY/XY | MW35C |

| Ucingo olune-enamel lwe-polyamide-imide | 220 | I-AIW | QXY | MW81C |

Umxholo weeKhemikhali, %

| Cu | Bi | Sb | As | Fe | Ni | Pb | S | Zn | Isikhokelo seROHS | |||

| Cd | Pb | Hg | Cr | |||||||||

| 99.90 | 0.001 | 0.002 | 0.002 | 0.005 | - | 0.005 | 0.005 | - | ND | ND | ND | ND |

Iipropati Zomzimba

| Indawo yokunyibilika – iLiquidus | 1083ºC |

| Indawo yokunyibilika – iSolidus | 1065ºC |

| Uxinano | 8.91 gm/cm3@ 20 ºC |

| Ubunzima obuthile | 8.91 |

| Ukumelana nombane | 1.71 microhm-cm @ 20 ºC |

| Ukuqhuba kombane** | 0.591 MegaSiemens/cm @ 20 ºC |

| Ukuqhuba kweThermal | 391.1 W/m · oK kwi-20 C |

| I-Coefficient yoKwandiswa koBushushu | 16.9 ·10-6 nge-ºC (20-100 ºC) |

| I-Coefficient yoKwandiswa koBushushu | 17.3 ·10-6 nge-ºC (20-200 ºC) |

| I-Coefficient yoKwandiswa koBushushu | 17.6·10-6 nge-ºC (20-300 ºC) |

| Umthamo othile wobushushu | 393.5 J/kg ·oK kwi-293 K |

| I-Modulus ye-Elasticity kwi-Tension | 117000 Mpa |

| Imodulus yoBulukhuni | 44130 Mpa |

Ukusetyenziswa kwefoyile yeCopper

1) Iziphethu zombane kunye nombane, iiswitshi

2) Iifreyimu zentsimbi

3) Izihlanganisi kunye neengcongolo zokushukuma

3) Intsimi yePCB

4) Intambo yonxibelelwano, Izixhobo zokukhusela iintambo, Ibhodi yefowuni ephathwayo

5) I-lamination yokuvelisa ibhetri ye-Ion ngefilimu ye-PI

6) Izinto zokuqokelela i-PCB (i-electrode backing)

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu