Wamkelekile kwiwebhusayithi zethu!

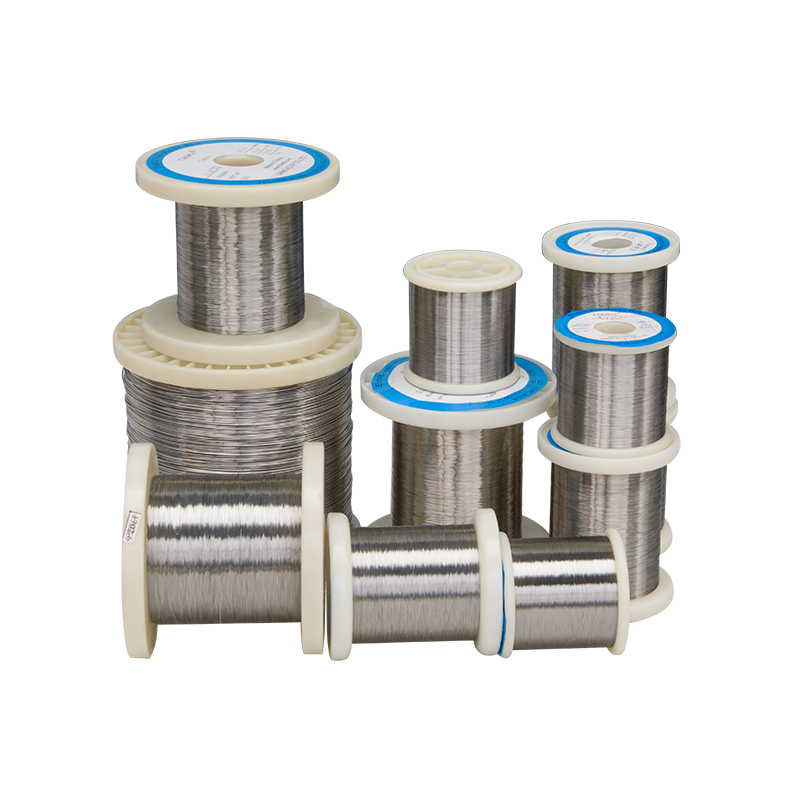

I-Aws A5.14 ASME Sfa 5.14 1.2mm 1.6mm 2.4mm 3.2mm Nickel Alloy Welding Wire/ Ernicrfe 5 Welding TIG Wire Rod Ernicrmo-3 Ernicrmo-3 Ernicrmo-13

Umgangatho:I-AWS A5.14 EN18274 ,ASME II, SFA-5.14,I-ERNiCu-7

Ubungakanani:0.8MM / 1.0MM / 1.2MM / 1.6MM / 2.4MM / 3.2MM

Ifomu:I-MIG(15kg/spool), I-TIG(5kg/box)

Uthotho lwe-Weling:I-ERNiCrMo-3,I-ERNiCrMo-4,I-ERNiCrMo-13,I-ERNiCrFe-3,I-ERNiCrFe-7,I-ERNiCr-3,I-ERNiCr-7,I-ERNiCu-7,I-ERNi-1IIPARAMETHA ZOKUWELDA

| Inkqubo | Ububanzi | I-Voltage | I-Amperage | Igesi |

| I-TIG | .035″ (0.9mm) .045″ (1.2mm) 1/16″ (1.6mm) 3/32″ (2.4mm) 1/8″ (3.2mm) | 12-15 13-16 14-18 15-20 15-20 | 60-90 80-110 90-130 120-175 150-220 | 100% Argon 100% Argon 100% Argon 100% Argon 100% Argon |

| I-MIG | .035″ (0.9mm) .045″ (1.2mm) 1/16″ (1.6mm) | 26-29 28-32 29-33 | 150-190 180-220 200-250 | I-75% Argon+25% Helium I-75% Argon+25% Helium I-75% yeArgon + 25% yeHelium |

| I-SAW | 3/32″ (2.4mm) 1/8″ (3.2mm) 5/32″ (4.0mm) | 28-30 29-32 30-33 | 275-350 350-450 400-550 | I-Flux efanelekileyo ingasetyenziswa I-Flux efanelekileyo ingasetyenziswa I-Flux efanelekileyo ingasetyenziswa |

| Uhlobo | Umgangatho | Ulwakhiwo lwekhemikhali ye-Manin % | Isicelo esiqhelekileyo |

| Ucingo lokuwelda lweNickel | A5.14I-ERNi-1 | I-Ni ≥ 93 Ti3 Al1 Cr– Mo– | I-ERNi-1 isetyenziselwa ukuwelda i-GMAW, i-GTAW kunye ne-ASAW ye-Nickel 200 kunye ne-201, idibanisa ezi alloys kwiintsimbi ezingatyiwayo nezekhabhoni, kunye nezinye iintsimbi zesiseko se-nickel kunye ne-copper-nickel. Ikwasetyenziselwa ukugquma intsimbi. |

| Ucingo lweNiCuwelding | A5.14 ERNiCu-7 | Ngo-65 Cr– Mo– Ti2 Okunye: Cu | I-ERNiCu-7 yintambo esisiseko se-copper-nickel alloy yokuwelda i-GMAW kunye ne-GTAW ye-Monel alloys 400 kunye ne-404. Ikwasetyenziselwa ukugquma intsimbi emva kokufaka okokuqala Umaleko we-610 nickel. |

| Ucingo lokuwelda lweCuNi | A5.7 ERCuNi | Ni 30 Cr– Mo– Okunye: Cu | I-ERCuNi isetyenziselwa ukuwelda intsimbi yegesi kunye ne-tungsten arc welding yegesi. Ingasetyenziswa nangokuwelda i-oxy-fuel ye-70/30, 80/20, kunye ne-90/10 copper nickel alloys. Umaleko wesithintelo se-nickel alloy 610 uyacetyiswa ngaphambi kokuba kugqunywe intsimbi ngenkqubo yokuwelda ye-GMAW. |

| Ucingo lokuwelda lweNiCr | A5.14 ERNiCrFe-3 | Ni≥ 67 Cr 20 Mo— Mn3 Nb2.5 Fe2 | Ii-electrode ze-Type ENiCrFe-3 zisetyenziselwa ukuwelda ii-alloys ze-nickel-chromium-iron kuzo kunye nokuwelda okwahlukileyo phakathi kwee-alloys ze-nickel-chromium-iron kunye neentsimbi okanye iintsimbi ezingenasici. |

| A5.14 ERNiCrFe-7 | Ni: Phumla Cr 30 Fe 9 | Uhlobo lwe-ERNiCrFe-7 lusetyenziselwa ukuwelda i-gas-tungsten-arc kunye ne-gas-metal-arc welding ye-INCONEL 690. | |

| Ucingo lokuwelda lweNiCrMo | A5.14 ERNiCrMo-3 | Ni≥ 58 Cr 21 Mo 9 Nb3.5 Fe ≤1.0 | I-ERNiCrMo-3 isetyenziswa kakhulu kwi-tungsten yegesi kunye ne-arc yesinyithi segesi kunye neentsimbi ezisisiseko ezihambelanayo. Ikwasetyenziselwa ukuwelda i-Inconel 601 kunye ne-Incoloy 800. Ingasetyenziselwa ukuwelda indibaniselwano yesinyithi eyahlukileyo efana nentsimbi, intsimbi engagqwaliyo, i-Inconel kunye nee-alloys ze-Incoloy. |

| A5.14 ERNiCrMo-4 | Ukuphumla kweNi Cr 16 Mo 16 W3.7 | I-ERNiCrMo-4 isetyenziselwa ukuwelda izinto zesiseko se-nickel-chromium-molybdenum kuzo, kwisinyithi nakwezinye ii-alloys zesiseko se-nickel kunye nentsimbi yokugquma. | |

| A5.14 ERNiCrMo-10 | Ukuphumla kweNi Cr 21 Mo 14 W3.2 Fe 2.5 | I-ERNiCrMo-10 isetyenziselwa ukuwelda izinto zesiseko se-nickel-chromium-molybdenum kuzo, kwintsimbi nakwezinye ii-alloys zesiseko se-nickel, nakwiintsimbi zokugquma. Ingasetyenziselwa ukuwelda iintsimbi ezingenasici ze-duplex, super duplex. | |

| A5.14 ERNiCrMo-14 | Ukuphumla kweNi Cr 21 Mo 16 W3.7 | I-ERNiCrMo-14 isetyenziselwa ukuwelda i-gas-tungsten-arc kunye ne-gas-metal-arc ye-duplex, i-super-duplex kunye ne-super-austenitic stainless steels, kunye ne-nickel alloys ezifana ne-UNS N06059 kunye ne-N06022, i-INCONEL alloy C-276, kunye ne-INCONEL alloys 22, 625, kunye ne-686. |

Bhala umyalezo wakho apha uze uwuthumele kuthi

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu