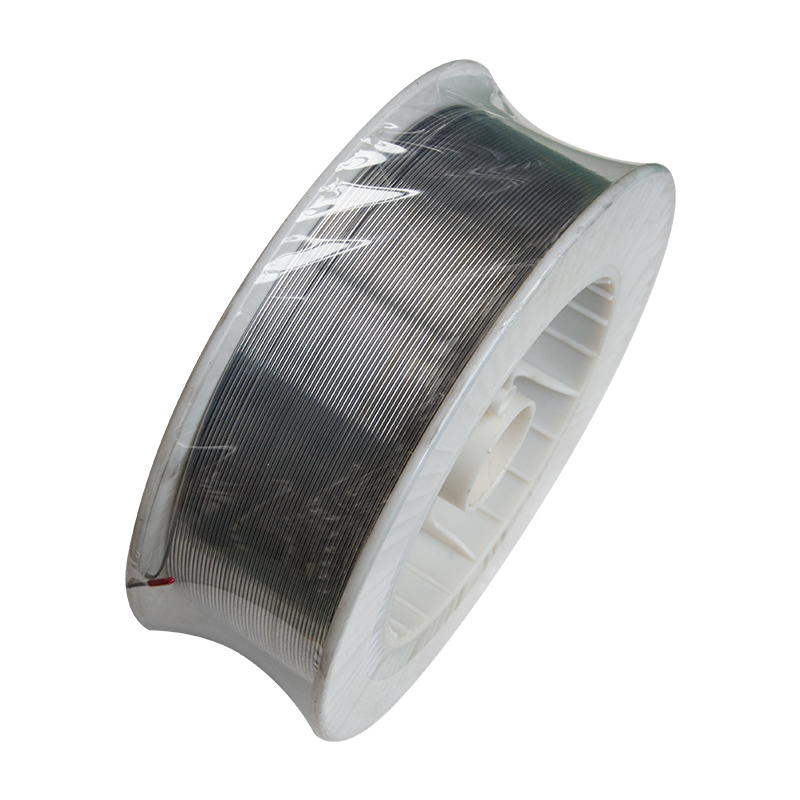

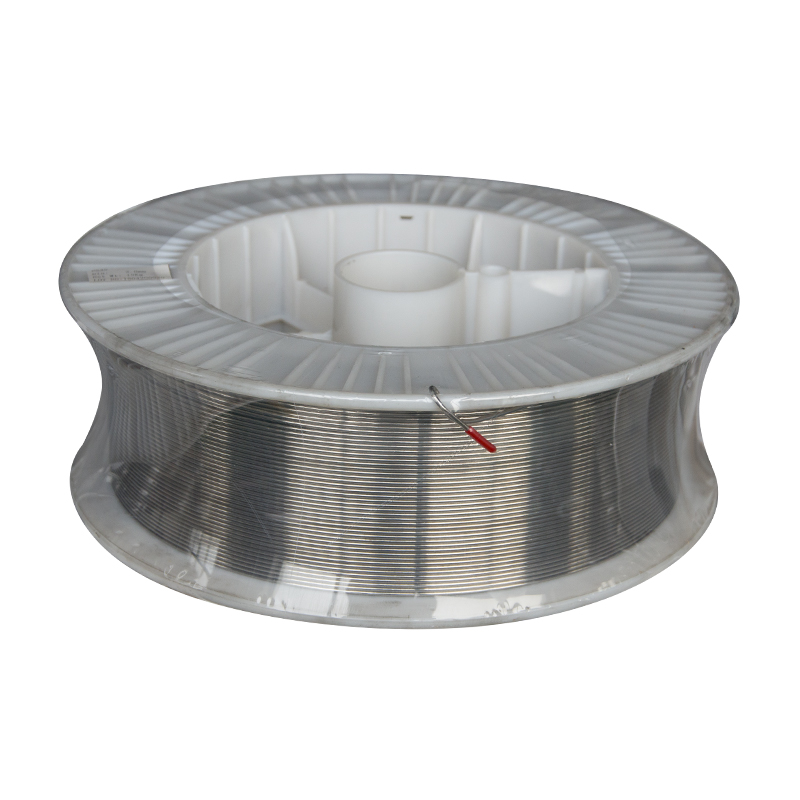

I-ASME Sfa 5.14 Ernicr-3 Nickel Alloy 80 Inconel 600 Alloy MIG Welding Wire TIG Welding Rod

I-Inconel 600 yi-alloy ye-nickel-chromium enokumelana okuhle kakhulu ne-organic acids kwaye isetyenziswa kakhulu ekucutshungulweni kwe-fatty acid. Umxholo ophezulu we-nickel we-Inconel 600 ubonelela ngokumelana okuhle nokugqwala phantsi kweemeko zokunciphisa, kunye nomxholo wayo we-chromium, ukumelana phantsi kweemeko ze-oxidizing. I-alloy ayichaphazeleki kakhulu kukuqhekeka kwe-chloride stress-corrosion. Ikwasetyenziswa kakhulu kwimveliso nasekuphatheni iikhemikhali ze-caustic soda kunye ne-alkali. I-Alloy 600 ikwayisixhobo esibalaseleyo sokusetyenziswa kobushushu obuphezulu esifuna indibaniselwano yokumelana nobushushu kunye nokugqwala. Ukusebenza kakuhle kwe-alloy kwiindawo ezishushu ze-halogen kwenza ukuba ibe lukhetho oludumileyo kwiinkqubo ze-organic chlorination. I-Alloy 600 ikwamelana ne-oxidation, carburization, kunye ne-nitridation.

Kwimveliso ye-titanium dioxide nge-chloride, i-titanium oxide yendalo (i-illmenite okanye i-rutile) kunye neegesi ze-chlorine ezishushu zasabela ukuvelisa i-titanium tetrachloride. I-Alloy 600 isetyenziswe ngempumelelo kule nkqubo ngenxa yokumelana kwayo okuhle nokugqwala yigesi ye-chlorine eshushu. Le ngxube ifunyenwe isetyenziswa kakhulu kwisithando somlilo nakwintsimi yokulungisa ubushushu ngenxa yokumelana kwayo okuhle nokugqwala kunye nokukhula kwi-980°C. Ingxube ikwafunyenwe isetyenziswa kakhulu ekuphatheni iindawo zamanzi, apho iintsimbi ezingenasici ziye zasilela ngokuqhekeka. Isetyenziswe kwinani lee-reactors zenyukliya kuquka ukubilisa ijenereyitha yomphunga kunye neenkqubo zokuhambisa amanzi eziphambili.

Ezinye iindlela eziqhelekileyo zokusetyenziswa ziinqanawa zokucubungula iikhemikhali kunye nemibhobho, izixhobo zokunyanga ubushushu, iinxalenye zeenjini zeenqwelo-moya kunye neefreyimu zomoya, iindawo ze-elektroniki, kunye nee-reactor zenyukliya.

Ukwenziwa kweeKhemikhali

| Ibanga | I-Ni% | Mn% | I-Fe% | I-Si% | I-Cr% | C% | I-Cu% | S% |

| I-Inconel 600 | Ubuncinane be-72.0 | Ubuninzi 1.0 | 6.0-10.0 | Ubuninzi 0.50 | 14-17 | Ubuninzi 0.15 | Ubuninzi 0.50 | Ubuninzi 0.015 |

Iinkcukacha

| Ibanga | Umgangatho waseBritane | Inombolo yeWerkstoff | I-UNS |

| I-Inconel 600 | I-BS 3075 (NA14) | 2.4816 | N06600 |

Iipropati Zomzimba

| Ibanga | Uxinano | Indawo yokunyibilika |

| I-Inconel 600 | 8.47 g/cm3 | 1370°C-1413 °C |

Iipropati zoomatshini

| I-Inconel 600 | Tensile strength | Unikeze Amandla | Ukwandiswa | Ubunzima bukaBrinell (HB) |

| Unyango lwe-Annealing | 550 N/mm² | 240 N/mm² | 30% | ≤195 |

| Unyango lweSisombululo | 500 N/mm² | 180 N/mm² | 35% | ≤185 |

Umgangatho Wethu Wemveliso

| Ibhari | Ukubumba | Umbhobho | Iphepha/Umcu | Ucingo | Izixhobo | |

| I-ASTM | I-ASTM B166 | I-ASTM B564 | I-ASTM B167/B163/B516/B517 | I-AMS B168 | I-ASTM B166 | I-ASTM B366 |

Ukuwelda kwe-Inconel 600

Naziphi na iinkqubo zokuwelda zemveli zingasetyenziselwa ukuwelda i-Inconel 600 kwii-alloys ezifanayo okanye ezinye iintsimbi. Ngaphambi kokuwelda, kufuneka kufudunyezwe kwangaphambili kwaye naliphi na ibala, uthuli okanye uphawu kufuneka lususwe ngebrashi yocingo lwentsimbi. Malunga nobubanzi obuyi-25mm ukuya kumphetho wokuwelda wesinyithi esisisiseko kufuneka sikhazimliswe ukuze sikhanye.

Cebisa ucingo lokugcwalisa malunga nokuwelda i-Inconel 600: ERNiCr-3

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu