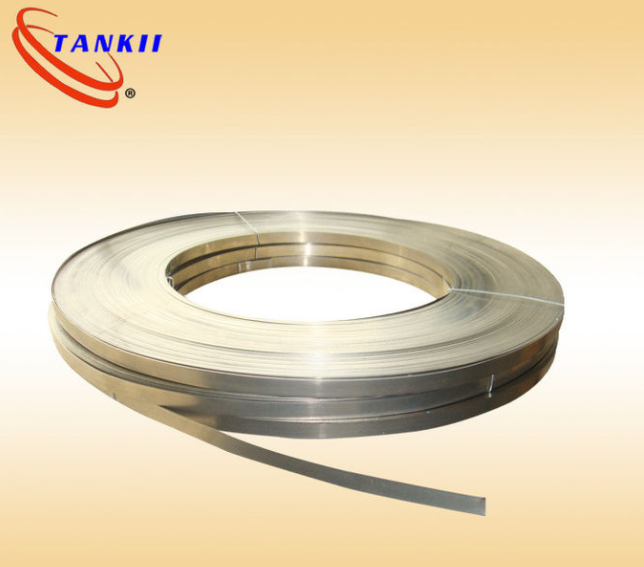

Intambo ye-1Cr13Al4 eqaqambileyo ethe tyaba enobubanzi obuyi-5 – 310mm ye-FeCrAl Alloy

Indawo Yokusetyenziswa: Isetyenziswa kakhulu kwizithando zomlilo zoshishino, izixhobo zasekhaya, izithando zomlilo zoshishino, isinyithi, oomatshini, iinqwelomoya, iimoto, ezomkhosi kunye nezinye izimboni ezivelisa izinto zokufudumeza kunye nezinto zokuxhathisa.

Iiresistor ezifakwe kwibhodi yocingo eprintiweyo ziya kuba luncedo ekwenzeni iipakethe zibe ncinci ngokuthembeka okuphezulu kunye nokusebenza kombane okuphuculweyo. Ukudibanisa ukusebenza kweresistor kwi-substrate ye-laminate kukhulula indawo yomphezulu we-PWB esetyenziswa zizinto ezihlukeneyo, okuvumela ukusebenza kwesixhobo okwandisiweyo ngokubekwa kwezinto ezisebenzayo ngakumbi. Ii-alloy ze-nickel-chromium zinokumelana okuphezulu kombane, okwenza ukuba zibe luncedo ekusebenziseni kwiintlobo ngeentlobo zezicelo. I-nickel kunye ne-chromium zixutywe nge-silicon kunye ne-aluminium ukuphucula uzinzo lobushushu kunye nokunciphisa i-coefficient yobushushu yokumelana. Umaleko omncinci wefilimu osekelwe kwi-alloy ze-nickel-chromium ubekwe rhoqo kwimiqulu yefoyile yobhedu ukwenza izinto zokusetyenziswa kwe-resistor efakwe ngaphakathi. Umaleko omncinci wefilimu oncitshisiweyo phakathi kobhedu kunye ne-laminate unokunqunyulwa ngokukhetha ukwenza iiresistor ezihlukeneyo. Iikhemikhali zokunqunyulwa zixhaphakile kwiinkqubo zemveliso ye-PWB. Ngokulawula ubukhulu bee-alloy, amaxabiso okumelana neshiti ukusuka kwi-25 ukuya kwi-250 ohm/sq. afunyanwa. Eli phepha liza kuthelekisa izinto ezimbini ze-nickel-chromium kwiindlela zazo zokugrumba, ukufana, ukuphathwa kwamandla, ukusebenza kobushushu, ukunamathela kunye nesisombululo sokugrumba.

| Igama lebrand | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Ulwakhiwo oluphambili lweekhemikhali% | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| RE | elifanelekileyo isixa | elifanelekileyo isixa | elifanelekileyo isixa | elifanelekileyo isixa | elifanelekileyo isixa | elifanelekileyo isixa | elifanelekileyo isixa | |

| Fe | Ukuphumla | Ukuphumla | Ukuphumla | Ukuphumla | Ukuphumla | Ukuphumla | Ukuphumla | |

| Inombolo 0.5 | Umhla 1.8-2.2 | |||||||

| Ubuninzi. buyaqhubeka ubushushu benkonzo i-element (ºC) | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| Ukuxhathisa μΩ.m,20ºC | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| Uxinano (g/cm3) | 7.4 | 7.10 | 7.16 | 7.25 | 7.35 | 7.10 | 7.10 | |

| Ubushushu ukuhanjiswa komoya I-KJ/mhºC | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| I-Coefficient ye ukwandiswa kwemigca α×10-6/ºC | 15.4 | 16.0 | 14.7 | 15.0 | 13.5 | 16.0 | 16.0 | |

| Iqondo lokunyibilikaºC | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Tensile strength I-Mpa | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| Ukwandiswa e ukuqhekeka % | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| Utshintsho lwe indawo % | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| Phinda ugobe imvamisa (F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| Ubulukhuni (HB) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| I-Micrographic isakhiwo | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | |

| Imagnethi iipropati | Imagnethi | Imagnethi | Imagnethi | Imagnethi | Imagnethi | Imagnethi | Imagnethi | |

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu