I-0cr15al5 Bright Annealed Fecral Alloy Strip yeResistor

I-0cr15al5 Bright Annealed Fecral Alloy Strip yeResistor

Udidi: 1Cr13AL4, 0Cr15AL5, 0Cr23AL5, 0Cr25AL5, 0Cr21AL6Nb0Cr27AL7Mo2

Ubungakanani: Ucingo: 0.15~10mm

Ibha: 12 ~ 120mm

| Iipropati/Ibanga | 1Cr13Al4 | 0Cr21Al4 | 0Cr21Al6 | 0Cr23Al5 | 0Cr25Al5 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Ikhemikhali ephambili ukwakheka (%) | Cr | 12.0-15.0 | 18.0-21.0 | 19.0-22.0 | 22.5-24.5 | 23.0-26.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 3.0-4.2 | 5.0-7.0 | 4.2-5.0 | 4.5-6.5 | 5.0-7.0 | 6.0-7.0 | |

| Fe | Ibhalansi | Ibhalansi | Ibhalansi | Ibhalansi | Ibhalansi | Ibhalansi | Ibhalansi | |

| Re | elifanelekileyo | elifanelekileyo | elifanelekileyo | elifanelekileyo | elifanelekileyo | elifanelekileyo | elifanelekileyo | |

| Inombolo:0.5 | UMvulo:1.8-2.2 | |||||||

| Inkonzo eqhubekayo ephezulu ubushushu bento | 950 | 1100 | 1250 | 1250 | 1250 | 1350 | 1400 | |

| Ukumelana ne-resistance kwi-20oC (μΩ @ m) | 1.25+-0.08 | 1.23+-0.06 | 1.42+-0.07 | 1.35+-0.07 | 1.42+-0.06 | 1.45+-0.07 | 1.53+-0.07 | |

| Ubuninzi (g/cm3) | 7.4 | 7.35 | 7.16 | 7.25 | 7.1 | 7.1 | 7.1 | |

| Ukuqhuba kobushushu (KJ/m@ h@ oC) | 52.7 | 46.9 | 63.2 | 60.2 | 46.1 | 46.1 | 45.2 | |

| I-coefficient yemigca ulwandiso(α × 10-6/oC) | 15.4 | 13.5 | 14.7 | 15 | 16 | 16 | 16 | |

| Iqondo lokunyibilika (malunga )(oC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Ukwandiswa ngexesha lokuqhekeka (%) | ≥16 | ≥12 | ≥12 | ≥12 | ≥12 | ≥12 | ≥10 | |

| Ulwakhiwo lweMicrographic | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | |

| Iimpawu zeMagnetic | imagnethi | imagnethi | imagnethi | imagnethi | imagnethi | imagnethi | imagnethi | |

Ngokuphathelele le alloy yokufudumeza yombane, singabonelela ngeengcingo ezahlukeneyo, iibha, iipleyiti, iistrips, iirod, njl.njl.

Inkcazo

Ngeempawu zokuxhathisa okuphezulu, ukumelana nombane okuphantsi, ubushushu obuphezulu bokusebenza, ukumelana nokugqwala okuhle phantsi kobushushu obuphezulu. Isetyenziswa kakhulu kwi-cooker yombane ye-ceramic, nakwi-industrial furnace.

Ukusetyenziswa

Isetyenziswa kakhulu kwiinjini zombane, iinjini zombane zedizili, iimoto zemetro kunye neenjini ezihamba ngesantya esiphezulu njl.njl. inkqubo yeebhuleki yokumelana neebhuleki, isitya sokupheka seceramic sombane, kunye nesithando somlilo semizi-mveliso.

Iimbonakalo

Ukusebenza okuzinzileyo; Ukuchasana ne-oxidation; Ukumelana nokugqwala; Uzinzo kubushushu obuphezulu; Amandla amahle okwenza iikhoyili; Imeko efanayo kwaye intle yomphezulu engenamabala.

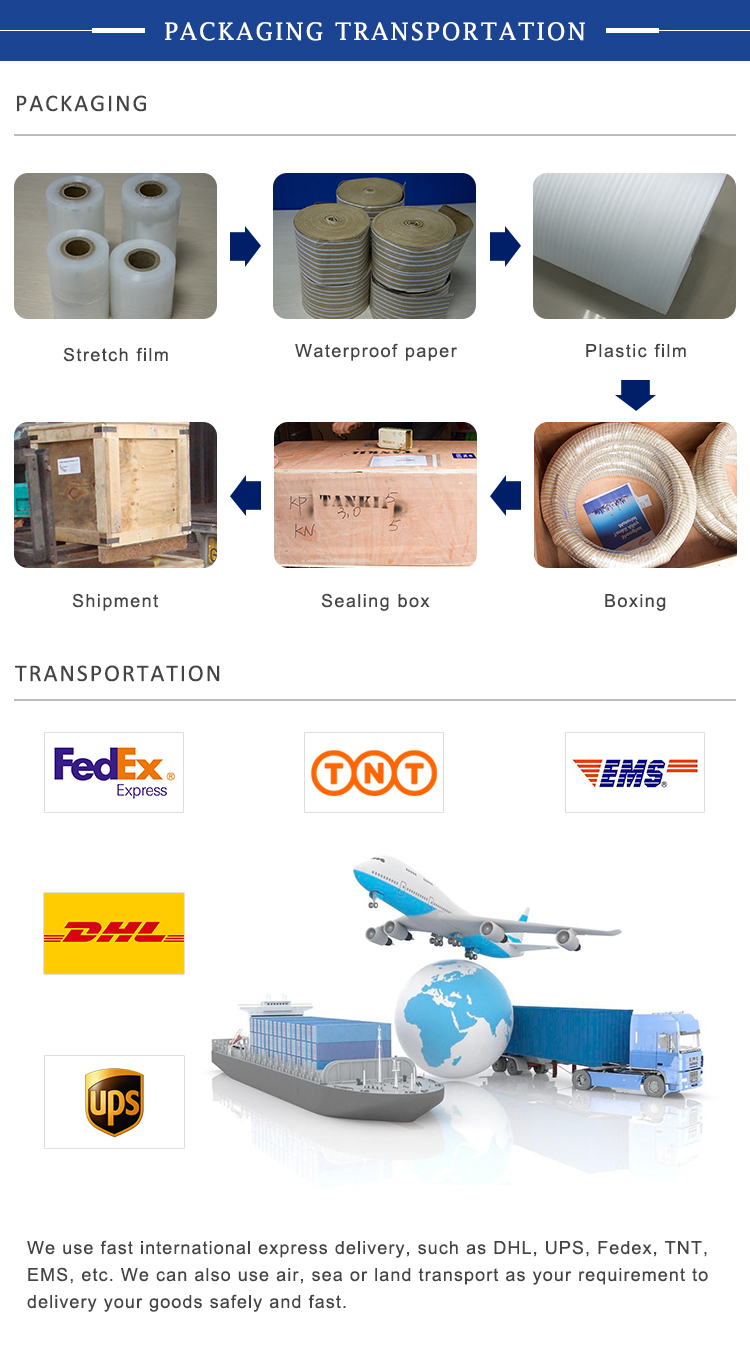

Iinkcukacha zokupakisha

1) Ikhoyili (iplastiki ephothiweyo) + ikesi yomthi ecinezelweyo + ipalethi

2) Ikhoyili (iplastiki) + ibhokisi + ipalethi

Iimveliso kunye neenkonzo:

1). Ipasi: Isatifikethi se-ISO9001, kunye ne-SO14001certification;

2). Iinkonzo zokuhlawula emva kokuthengisa;

3). Iodolo encinci yamkelwe;

4). Iipropati ezizinzileyo kubushushu obuphezulu;

5). Ukuhanjiswa okukhawulezayo;

.

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu