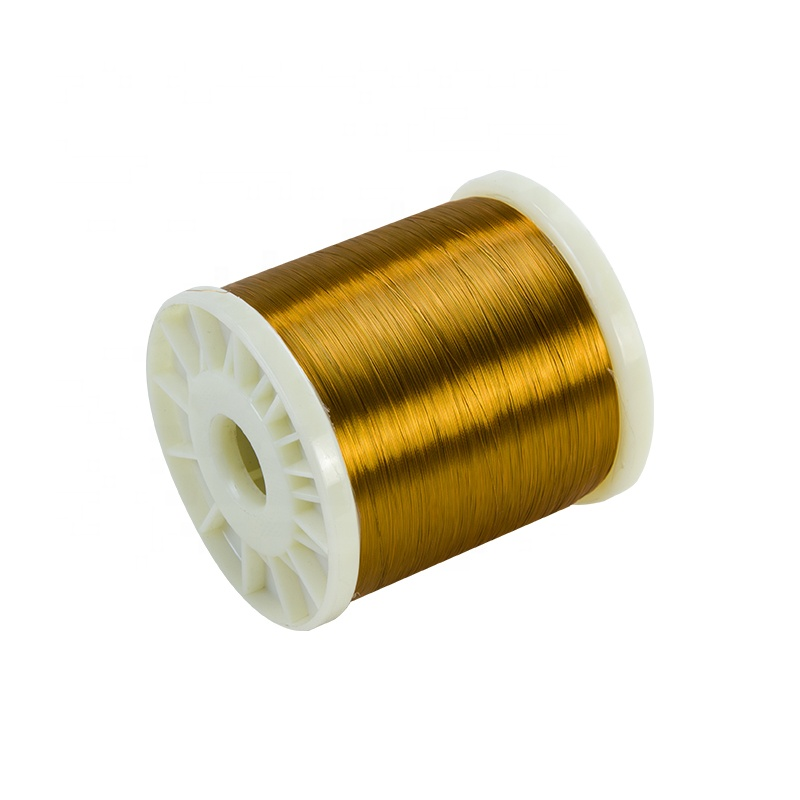

I-0.2mm 130 Class Enameled Wire Colored Round Copper Alloy Manganin

I-130 Class Colored Copper Alloy Manganin Enameled Wire

1. Inkcazelo Jikelele yezinto ezisetyenzisiweyo

I-alloy ye-nickel yobhedu, enokumelana nombane okuphantsi, iyakwazi ukumelana nobushushu nokugqwala, kulula ukuyicubungula kwaye idityaniswe nge-lead. Isetyenziselwa ukwenza izinto eziphambili kwi-thermal overload relay, i-thermal resistance breaker, kunye nezixhobo zombane. Ikwayinto ebalulekileyo kwi-electrical heating cable. Ifana ne-s type cupronickel. Okukhona i-Nickel ixutywe ngakumbi, kokukhona umphezulu umhlophe ngesilivere.

3. Ukwakhiwa kweekhemikhali kunye nePropathi ephambili yeCu-Ni Low Resistance Alloy

| IGrade yeeProperties | I-CuNi1 | I-CuNi2 | I-CuNi6 | I-CuNi8 | I-CuMn3 | I-CuNi10 | |

| Ulwakhiwo oluPhambili lweeKhemikhali | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | I-Bal | I-Bal | I-Bal | I-Bal | I-Bal | I-Bal | |

| Ubushushu obuphezulu beNkonzo eQhubekayo (oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Ukuqina kwakhona kwi-20oC (Ωmm2/m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Uxinano (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| Ukuqhuba kwe-Thermal (α×10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Amandla okuThamba (i-Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| I-EMF vs Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Indawo yokunyibilika eqikelelweyo (oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Ulwakhiwo lweMicrographic | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | |

| Ipropati yeMagnetic | akukho | akukho | akukho | akukho | akukho | akukho | |

| IGrade yeeProperties | I-CuNi14 | I-CuNi19 | I-CuNi23 | I-CuNi30 | I-CuNi34 | I-CuNi44 | |

| Ulwakhiwo oluPhambili lweeKhemikhali | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | I-Bal | I-Bal | I-Bal | I-Bal | I-Bal | I-Bal | |

| Ubushushu obuphezulu beNkonzo eQhubekayo (oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| Ukuqina kwakhona kwi-20oC (Ωmm2/m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Uxinano (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Ukuqhuba kwe-Thermal (α×10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Amandla okuThamba (i-Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| I-EMF vs Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Indawo yokunyibilika eqikelelweyo (oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Ulwakhiwo lweMicrographic | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | |

| Ipropati yeMagnetic | akukho | akukho | akukho | akukho | akukho | akukho | |

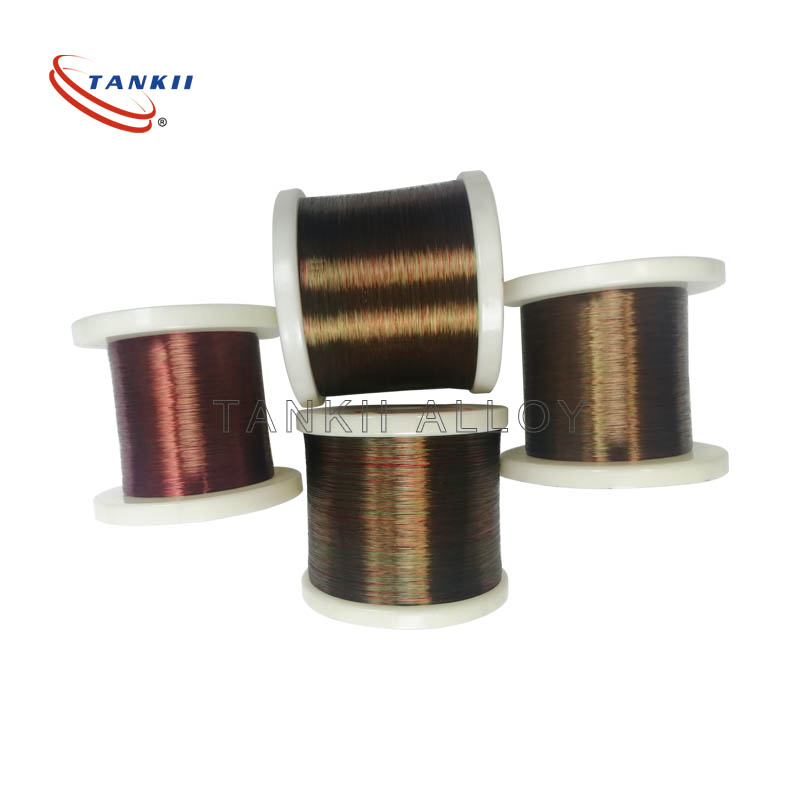

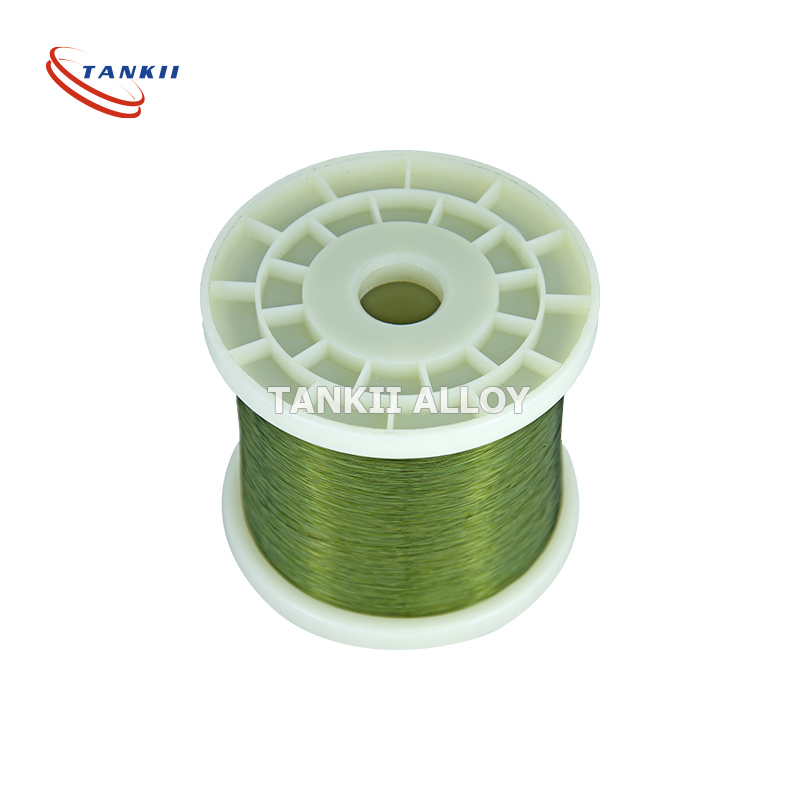

2. Intshayelelo kunye nezicelo ze-Enamelled Wire

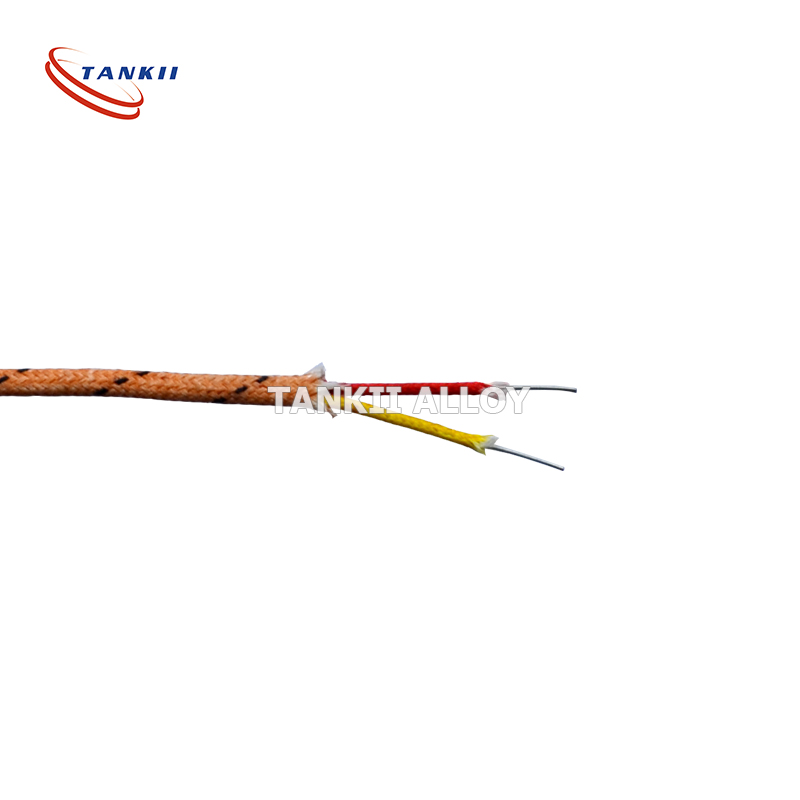

Nangona ichazwa njenge "enameled",ucingo olune-enamelEnyanisweni, ayigqunywanga ngomaleko wepeyinti ye-enamel okanye nge-enamel ye-vitreous eyenziwe ngomgubo weglasi oxutyiweyo. Intambo yemagnethi yanamhlanje idla ngokusebenzisa umaleko omnye ukuya kowesine (kwimeko yocingo olunefilimu ezine) we-polymer film insulation, edla ngokuba yimilo emibini eyahlukeneyo, ukubonelela ngomaleko oqinileyo noqhubekayo wokukhusela. Iifilimu zokukhusela intambo yemagnethi zisebenzisa (ngolandelelwano lobushushu obukhulayo) i-polyvinyl formal (Formar), i-polyurethane, i-polyimide, i-polyamide, i-polyamide, i-polyster, i-polyester-polyimide, i-polyamide-polyimide (okanye i-amide-imide), kunye ne-polyimide. Intambo yemagnethi egqunyiweyo ye-polyimide iyakwazi ukusebenza ukuya kuthi ga kwi-250 °C. Ukukhusela intambo yemagnethi etyebileyo yesikwere okanye yengxande kudla ngokwandiswa ngokuyisonga nge-polyimide okanye i-fiberglass tape enobushushu obuphezulu, kwaye ii-windings ezigqityiweyo zihlala zifakwe i-vacuum nge-varnish yokukhusela ukuphucula amandla okukhusela kunye nokuthembeka kwexesha elide kwe-winding.

Iikhoyili ezizixhasayo zibotshelelwa ngocingo olugqunywe ubuncinane ngeengqimba ezimbini, elona lingaphandle yi-thermoplastic edibanisa iijika kunye xa zifudunyezwa.

Ezinye iintlobo zokwambathisa ezifana nomsonto we-fiberglass onevarnish, iphepha le-aramid, iphepha le-kraft, i-mica, kunye nefilimu ye-polyester nazo zisetyenziswa kakhulu kwihlabathi liphela kwizicelo ezahlukeneyo ezifana nee-transformers kunye nee-reactors. Kwicandelo le-audio, ucingo lwesilivere oluyilwe, kunye nezinye izinto zokwambathisa, ezifana nomqhaphu (ngamanye amaxesha ozaliswa yi-agent/thickener ethile, efana ne-beeswax) kunye ne-polytetrafluoroethylene (PTFE) zinokufunyanwa. Izinto zokwambathisa ezindala ziquka umqhaphu, iphepha, okanye isilika, kodwa ezi ziluncedo kuphela kwizicelo zobushushu obuphantsi (ukuya kuthi ga kwi-105°C).

Ukuze kube lula ukwenziwa, ucingo oluthile lwemagnethi olukumgangatho ophantsi lune-insulation enokususwa bubushushu be-soldering. Oku kuthetha ukuba uqhagamshelo lombane eziphelweni lunokwenziwa ngaphandle kokususa i-insulation kuqala.

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu