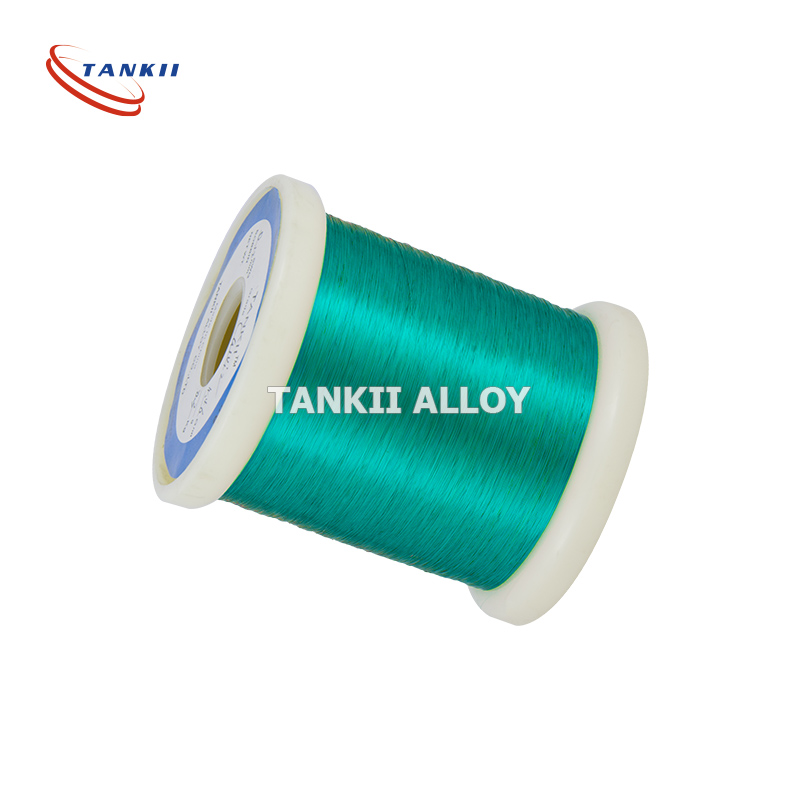

I-0.2mm 130 Class Enameled Wire Colored Round Copper Alloy Manganin

I-130 Class Colored Copper Alloy Manganin Enameled Wire

1. Inkcazelo Jikelele yezinto ezisetyenzisiweyo

I-alloy ye-nickel yobhedu, enokumelana nombane okuphantsi, iyakwazi ukumelana nobushushu nokugqwala, kulula ukuyicubungula kwaye idityaniswe nge-lead. Isetyenziselwa ukwenza izinto eziphambili kwi-thermal overload relay, i-thermal resistance breaker, kunye nezixhobo zombane. Ikwayinto ebalulekileyo kwi-electrical heating cable. Ifana ne-s type cupronickel. Okukhona i-Nickel ixutywe ngakumbi, kokukhona umphezulu umhlophe ngesilivere.

3. Ukwakhiwa kweekhemikhali kunye nePropathi ephambili yeCu-Ni Low Resistance Alloy

| IGrade yeeProperties | I-CuNi1 | I-CuNi2 | I-CuNi6 | I-CuNi8 | I-CuMn3 | I-CuNi10 | |

| Ulwakhiwo oluPhambili lweeKhemikhali | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | I-Bal | I-Bal | I-Bal | I-Bal | I-Bal | I-Bal | |

| Ubushushu obuphezulu beNkonzo eQhubekayo (oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Ukuqina kwakhona kwi-20oC (Ωmm2/m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Uxinano (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| Ukuqhuba kwe-Thermal (α×10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Amandla okuThamba (i-Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| I-EMF vs Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Indawo yokunyibilika eqikelelweyo (oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Ulwakhiwo lweMicrographic | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | |

| Ipropati yeMagnetic | akukho | akukho | akukho | akukho | akukho | akukho | |

| IGrade yeeProperties | I-CuNi14 | I-CuNi19 | I-CuNi23 | I-CuNi30 | I-CuNi34 | I-CuNi44 | |

| Ulwakhiwo oluPhambili lweeKhemikhali | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | I-Bal | I-Bal | I-Bal | I-Bal | I-Bal | I-Bal | |

| Ubushushu obuphezulu beNkonzo eQhubekayo (oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| Ukuqina kwakhona kwi-20oC (Ωmm2/m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Uxinano (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Ukuqhuba kwe-Thermal (α×10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Amandla okuThamba (i-Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| I-EMF vs Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Indawo yokunyibilika eqikelelweyo (oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Ulwakhiwo lweMicrographic | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | |

| Ipropati yeMagnetic | akukho | akukho | akukho | akukho | akukho | akukho | |

2. Intshayelelo kunye nezicelo ze-Enamelled Wire

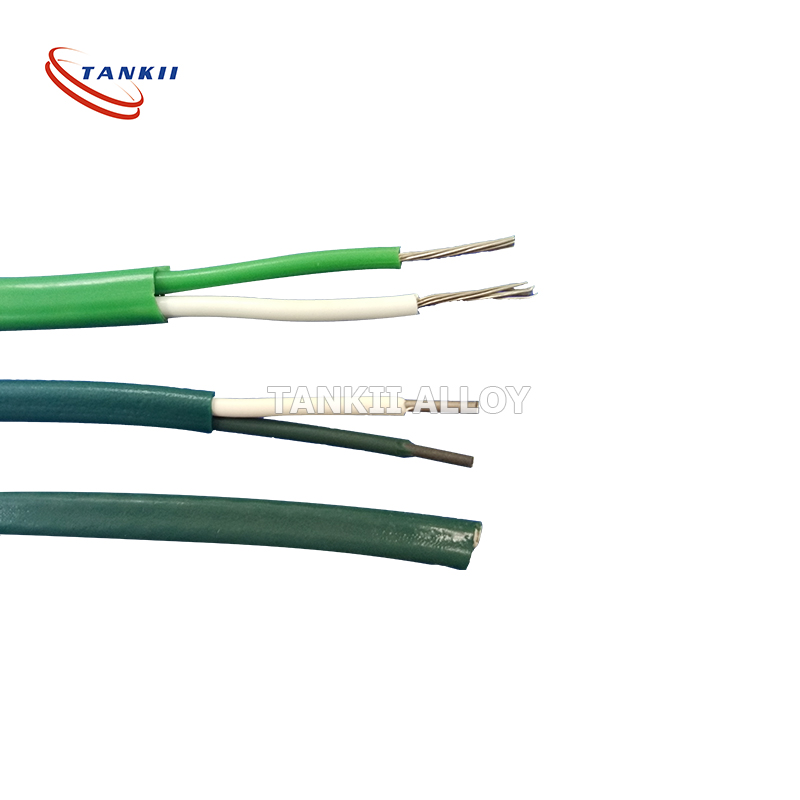

Nangona ichazwa njenge "enameled", i-enameled wire, eneneni, ayigqunywanga ngumaleko wepeyinti ye-enamel okanye nge-vitreous enamel eyenziwe ngomgubo weglasi oxutyiweyo. I-magnet wire yanamhlanje idla ngokusebenzisa umaleko omnye ukuya kowesine (kwimeko ye-quad-film type wire) we-polymer film insulation, edla ngokuba yimilo emibini eyahlukeneyo, ukubonelela ngomaleko oqinileyo noqhubekayo wokukhusela. Iifilimu zokukhusela i-magnet wire zisebenzisa (ngolandelelwano lobushushu obukhulayo) i-polyvinyl formal (Formar), i-polyurethane, i-polyimide, i-polyamide, i-polyster,i-polyester-polyimide, i-polyamide-polyimide (okanye i-amide-imide), kunye ne-polyimide. I-polyimide insulated magnet wire iyakwazi ukusebenza ukuya kuthi ga kwi-250 °C. Ukufakwa kwe-insulation ye-square okanye i-rectangular magnet wire etyebileyo kudla ngokwandiswa ngokuyisonga nge-polyimide okanye i-fiberglass tape enobushushu obuphezulu, kwaye ii-windings ezigqityiweyo zihlala zifakwe i-vacuum nge-insulation varnish ukuphucula amandla okufakwa kwe-insulation kunye nokuthembeka kwexesha elide kwe-winding.

Iikhoyili ezizixhasayo zibotshelelwa ngocingo olugqunywe ubuncinane ngeengqimba ezimbini, elona lingaphandle yi-thermoplastic edibanisa iijika kunye xa zifudunyezwa.

Ezinye iintlobo zokwambathisa ezifana nomsonto we-fiberglass onevarnish, iphepha le-aramid, iphepha le-kraft, i-mica, kunyei-polyesterIifilimu zikwasetyenziswa kakhulu kwihlabathi liphela kwiindlela ezahlukeneyo zokusebenza ezifana neetransformers kunye neereactors. Kwicandelo lesandi, ucingo lwesilivere oluyilwe ngayo, kunye nezinye izinto zokuthintela ubushushu, ezifana nomqhaphu (ngamanye amaxesha zigcwele uhlobo oluthile lwe-coagulating agent/thickener, efana ne-beeswax) kunye ne-polytetrafluoroethylene (PTFE) zinokufunyanwa. Izinto zokukhusela ubushushu ezindala ziquka umqhaphu, iphepha, okanye isilika, kodwa ezi ziluncedo kuphela kwiindlela ezisebenzisa ubushushu obuphantsi (ukuya kuthi ga kwi-105°C).

Ukuze kube lula ukwenziwa, ucingo oluthile lwemagnethi olukumgangatho ophantsi lune-insulation enokususwa bubushushu be-soldering. Oku kuthetha ukuba uqhagamshelo lombane eziphelweni lunokwenziwa ngaphandle kokususa i-insulation kuqala.

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu