Wamkelekile kwiiwebhusayithi zethu!

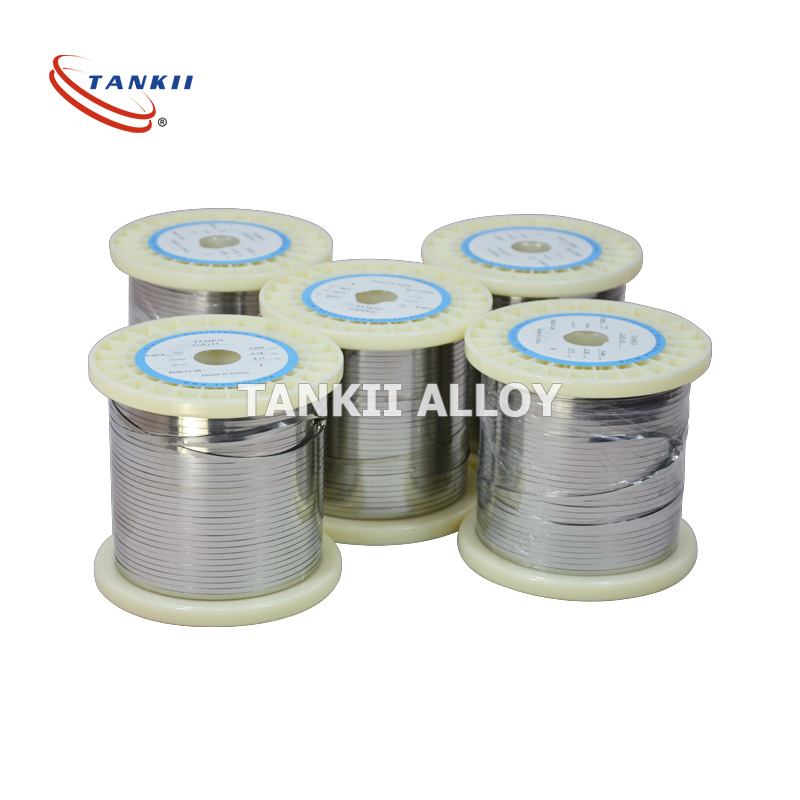

0.25mm 0Cr25Al5 ngocingo oluKhanyayo ukuya kwi-Industrial Furances

Ulwazi olusisiseko.

| Ipharamitha | Iinkcukacha | Ipharamitha | Iinkcukacha |

|---|---|---|---|

| Umzekelo NO. | 0cr25al5 | Ukuqulunqwa kwemichiza | 0cr25al5 |

| Igama lemveliso | I-Heating Resistance Strip | Iimpawu | Ukuxhathisa okuphezulu, I-oxidation elungileyo Ukuchasa |

| Elona qondo lobushushu liphezulu | 1300℃ | Ukuxinana | 7.1g/cm³ |

| Ukuxhathisa | 1.42 Ω·m | Ukwandisa | >20% |

| Isampulu | Inkxaso | Ipakethe yezoThutho | Amatyala omthi okanye iibhokisi |

| Inkcazo | 0.25mm | Uphawu lokuthengisa | Tankii |

| Imvelaphi | Jiangsu | Ikhowudi ye-HS | 7408220000 |

| Isakhono seMveliso | IiToni ezili-100/ngenyanga |

Ingcaciso yeMveliso

0.25mm 0cr25al5 Ukufudumeza ucingo lwe-Fecral Alloy kwintambo yokuIgnition Inkcazo ngokubanzi I-alloy ye-FeCrAl yenziwe ngubushushu obuphezulu, i-ferritic iron-chromium-aluminium alloy enokusetyenziswa kumaqondo obushushu ukuya kwi-1350degrees. Usetyenziso oluqhelekileyo lwe-FeCrAl lufana nezinto zokufudumeza zombane kwiziko lobushushu obuphezulu kunyango lobushushu, iiseramikhi, iglasi, intsimbi, kunye noshishino lombane. Uphawu: Ngobomi benkonzo ende.Ukufudumala ngokukhawuleza.Ukusebenza kakuhle kwe-thermal.Ubushushu obufanayo. Inokusetyenziswa ngokuthe nkqo. Xa isetyenziswa kwi-voltage elinganisiweyo, akukho nto iguquguqukayo.Lukhuseleko lokusingqongileyo ucingo lokufudumeza kombane. Kwaye enye indlela yocingo olubiza kakhulu lwe-nichrome. Ingenziwa ngokwezifiso ngokweemfuno zabathengi Iialloyi ze-FeCrAl ziphawulwa ngokumelana ne-oxidation okugqwesileyo kunye nozinzo oluhle kakhulu olukhokelela kubomi obude. Ngokuqhelekileyo zisetyenziswa kwizinto zokufudumeza zombane kwiziko loshishino kunye nezixhobo zasekhaya. I-alloy ye-Fe-Cr-Al ene-resistivity ephezulu kunye nobushushu bokusebenza kunoko kwe-NiCr alloy kwaye inexabiso eliphantsi. Usetyenziso I-Iron-chrome-aluminium i-resistor wire yombane isetyenziselwa ngokubanzi ukwenza izinto zokufudumeza zombane kwizixhobo zasekhaya kunye neziko loshishino. Usetyenziso oluqhelekileyo zii-ayini ezisicaba, oomatshini boku-ayina, izifudumezi zamanzi, ukubumba iplastiki kuyafa, iiayini zokudambisa, izinto zetsimbi ezigqunywe nge-tubular kunye nezinto zekhatriji. Indawo yesicelo Iimveliso zethu zisetyenziswa kakhulu kwizixhobo zonyango lobushushu, iinxalenye zemoto, ukwenziwa kwentsimbi kunye nentsimbi, ishishini aluminiyam, izixhobo metallurgical, izixhobo petrochemical, oomatshini iglasi, oomatshini ceramic, oomatshini bokutya, oomatshini bamayeza, kunye noshishino lobunjineli bamandla. Umxholo weMichiza, %

Iimpawu eziphambili zobugcisa be-FeCrAl Alloy:

| Izinto ze-alloy | Ukwakheka kweekhemikhali% | |||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | abanye | |

| ubuninzi(≤) | ||||||||||

| 1Cr13Al4 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 12.5-15.0 | - | 3.5-4.5 | Phumla | - |

| 0Cr15Al5 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 14.5-15.5 | - | 4.5-5.3 | Phumla | - |

| 0Cr25Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 23.0-26.0 | ≤0.60 | 4.5-6.5 | Phumla | - |

| 0Cr23Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 20.5-23.5 | ≤0.60 | 4.2-5.3 | Phumla | - |

| 0Cr21Al6 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 19.0-22.0 | ≤0.60 | 5.0-7.0 | Phumla | - |

| 0Cr19Al3 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 18.0-21.0 | ≤0.60 | 3.0-4.2 | Phumla | - |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.60 | 21.0-23.0 | ≤0.60 | 5.0-7.0 | Phumla | Nb dibanisa0.5 |

| 0Cr27Al7Mo2 | 0.05 | 0.025 | 0.025 | 0.2 | ≤0.40 | 26.5-27.8 | ≤0.60 | 6.0-7.0 | Phumla | |

| UphawuIpropati | 1Cr13Al4 | 1Cr21Al4 | 0Cr21Al6 | 0Cr23Al5 | 0Cr25Al5 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Inxalenye yekhemikhali engundoqo | Cr | 12.0-12.5 | 17.0-21.0 | 19.0-22.0 | 20.5-23.5 | 23.0-26.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 2.0-4.0 | 5.0-7.0 | 4.2-5.3 | 4.5-6.5 | 5.0-7.0 | 6.0-7.0 | |

| Fe | Ibhalansi | Ibhalansi | Ibhalansi | Ibhalansi | Ibhalansi | Ibhalansi | Ibhalansi | |

| Re | Ifanelekile | Ifanelekile | Ifanelekile | Ifanelekile | Ifanelekile | Ifanelekile | Ifanelekile | |

| Ukongeza Nb:0.5 | UkongezaMo:1.8-2.2 | |||||||

| Ubuninzi becandelo. sebenzisa ubushushu | 950 | 1100 | 1250 | 1250 | 1250 | 1350 | 1400 | |

| Indawo yokunyibilika | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1510 | |

| Ubuninzi be-g/cm3 | 7.40 | 7.35 | 7.16 | 7.25 | 7.10 | 7.10 | 7.10 | |

| Ukuxhathisa μΩ·m,20 | 1.25±0.08 | 1.23±0.06 | 1.42±0.07 | 1.35±0.06 | 1.45±0.07 | 1.45±0.07 | 1.53±0.07 | |

| Ukuqina kokuqina kweMpa | 588-735 | 637-784 | 637-784 | 637-784 | 637-784 | 637-784 | 684-784 | |

| Isantya sokwandisa% | 16 | 12 | 12 | 12 | 12 | 10 | ||

| Ukugoba okuphindaphindiweyo | 5 | 5 | 5 | 5 | 5 | |||

| Phakamisa ngokukhawuleza h/ | - | 80/1300 | 80/1300 | 50/1350 | ||||

| Ubushushu obuthile J/g. | 0.490 | 0.490 | 0.520 | 0.460 | 0.494 | 0.494 | 0.494 | |

| I-Coefficient ye-Heat Coefficient KJ/Mh | 52.7 | 46.9 | 63.2 | 60.1 | 46.1 | 46.1 | 45.2 | |

| Ukwandiswa komlinganiso womgca we-aX10-6/(20-1000) | 15.4 | 13.5 | 14.7 | 15.0 | 16.0 | 16.0 | 16.0 | |

| Ubulukhuni HB | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Microstructure | I-Ferritic | I-Ferritic | I-Ferritic | I-Ferritic | I-Ferritic | I-Ferritic | I-Ferritic | |

| Imagnethi | Imagnethi | Imagnethi | Imagnethi | Imagnethi | Imagnethi | Imagnethi | Imagnethi | |

Bhala umyalezo wakho apha kwaye uwuthumele kuthi

Iindidi zeemveliso

-

Ifowuni

-

I-imeyile

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Phezulu